Page 1074 - Softbound_Edition_19_en

P. 1074

Proportional

Proportional pressure reducing valve

Proportional pressure reducing valve pressure reducing valves

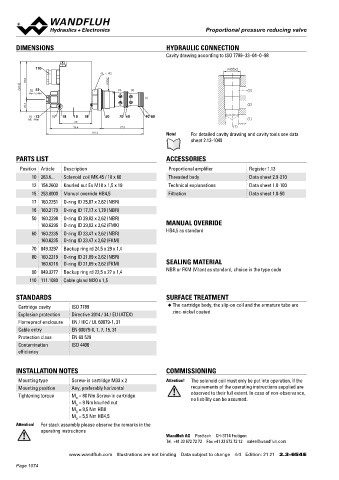

DIMENSIONS HYDRAULIC CONNECTION Proportional pressure control valve

Cavity drawing according to ISO 7789–33–04–0–98 Slip-in cartridge construction

• Direct-operated

110 M33x2 • Q = 3 l/min

s32 max

70.8 M33x2 • p max = 450 bar

93.3 15 (3) (2) • p T max = 20 bar, p N red max = 48 bar

MD=5.5Nm (3)

(1) DESCRIPTION FUNCTION APPLICATION

22.5 (2) Direct-operated proportional pressure control The proportional pressure control valve con- The compact valve has its application in hy-

cartridge for cavity MDPPR11 PI35. Due to the trols the pressure in the connection A (1). So- draulic systems, in which the pressure fre-

12 17 18 10 18 50 70 60 90 80 very compact installation dimensions, new ap- lenoid power and the pressure in the connec- quently has to be varied. The facility of electric

MD=9Nm (1) plication possibilities are offered. As standard tion A (1) increase proportionally to the sole- remote control of the valve, in conjunction with

60

96.4 77.9 (1) versions, two pressure ranges are available. noid current. The valve operates to a great process control systems, makes economical

181.2 Note! For detailed cavity drawing and cavity tools see data The adjustment is done by means of a Wand- extent independent of the pressure in the con- solutions with repetitive sequences possible.

sheet 2.13-1040 fluh proportional solenoid (VDE-Standard nection P (2). The increase of the pressure in Application fields are the pilot-operation of pro-

0580). The solenoid as well as the housing bot-

the connection A (1) to over the set value, e.g.

portional spool valves, the driving of control

tom made of steel are zinc coated and there- by an active consumer, is prevented by diver- pumps and motors as well as the controlling of

fore rust-protected. ting excess oil to the tank T (3). The back pres- the contact pressure of disc brake coatings.

PARTS LIST ACCESSORIES sure in T influences the pressure in A (1). With With the compact valve a minimum control oil

a current-free solenoid, the oil freely flows from volume is achieved.

Position Article Description Proportional amplifier Register 1.13 the consumer connection A to the connection

10 263.6... Solenoid coil MK.45 / 18 x 60 Threaded body Data sheet 2.9-210 T. For driving the valve, Wandfluh proportional

amplifiers are available (see Register 1.13).

12 154.2603 Knurled nut Ex M18 x 1,5 x 18 Technical explanations Data sheet 1.0-100

15 253.8000 Manual override HB4,5 Filtration Data sheet 1.0-50 TYPE CODE

17 160.2251 O-ring ID 25,07 x 2,62 (NBR) M D P PR11 - - #

18 160.2170 O-ring ID 17,17 x 1,78 (NBR) Pressure reducing valve

50 160.2298 O-ring ID 29,82 x 2,62 (NBR) Direct operated

160.6296 O-ring ID 29,82 x 2,62 (FMK) MANUAL OVERRIDE Proportional

HB4,5 as standard

60 160.2235 O-ring ID 23,47 x 2,62 (NBR) Slip-in cartridge, diameter 11 mm

160.6235 O-ring ID 23,47 x 2,62 (FKM) Nominal pressure range p N red 25 bar 25

70 049.3297 Backup ring rd 24,5 x 29 x 1,4 48 bar 48

Nominal voltage U 12 VDC G12

80 160.2219 O-ring ID 21,89 x 2,62 (NBR) N 24 VDC G24

160.6216 O-ring ID 21,89 x 2,62 (FKM) SEALING MATERIAL Design-Index (Subject to change) 20

90 049.3277 Backup ring rd 22,5 x 27 x 1,4 NBR or FKM (Viton) as standard, choice in the type code

110 111.1080 Cable gland M20 x 1,5

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

STANDARDS SURFACE TREATMENT Denomination Direct operated proportional pressure 15 Fluid Mineral oil, other fluid on request

Cartridge cavity ISO 7789 ◆ The cartridge body, the slip-on coil and the armature tube are Construction reducing valve Contamination efficiency ISO 4406:1999, class 18/16/13

50

Required filtration grade (ß 6...10 ≥ 75)

Slip-in cartridge for cavity acc.

Explosion protection Directive 2014 / 34 / EU (ATEX) zinc-nickel coated to Wandfluh-standard 74 (refer to data sheet 1.0-50/2)

40

Flameproof enclosure EN / IEC / UL 60079-1, 31 Actuation Proportional solenoid Oil temperature Acrylnitril -25…+70 °C

/s...320 mm /s 30

Viscosity range

Mounting

min. 2 head screws crosswise M4 x 60

2

Cable entry EN 60079-0, 1, 7, 15, 31 Ambient temperature -25…50 °C Maximum pressure 12 mm 2 T(3)

= 450 bar (final testing at WAG up to 350 bar)

p max

Protection class EN 60 529 Mounting position any Nominal pressure range p N red = 25 bar, p N red = 48 bar

A(1)

Contamination ISO 4406 Fastening torque M D = 2,8 Nm (quality 8.8) Volume flow range 25 bar Q = 0 - 1 l/min p → A A →T

48 bar Q = 0 -3 l/min

Weight

m = 0,45 kg

efficiency Pressure decrease 1 → 3 ∆p red min. < lower than nominal pressure

P(2)

at nominal volume flow

ELECTRICAL SPECIFICATIONS Leakage volume flow see characteristics

INSTALLATION NOTES COMMISSIONING Construction Proportional solenoid, wet pin push Hysteresis 70,3 ≤ 4 % (at optimal dither signal)

14

type, pressure tight

Mounting type Screw-in cartridge M33 x 2 Attention! The solenoid coil must only be put into operation, if the Standard nominal voltage U = 12 VDC U = 24 VDC

Mounting position Any, preferably horizontal requirements of the operating instructions supplied are Limiting current I G = 1250 mA I = 680 mA

G

Tightening torque M = 80 Nm Screw-in cartridge observed to their full extent. In case of non-observance, Relative duty factor 100 % ED / DF SYMBOL

no liability can be assumed.

D

M = 9 Nm knurled nut Protection class IP 65 acc. to EN 60 529

D

M = 9,5 Nm HB0 Connection / Power supply Over device plug connection to A(1)

EN 175301-803 (DIN 43650)

D

M = 5,5 Nm HB4,5 ISO 4400

D

Attention! For stack assembly please observe the remarks in the

operating instructions

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com P(2) T(3)

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 21 21 2.3-654 E Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.3-671E 1/2

CH-3714 Frutigen Edition 16 18

Page 1074