Page 1070 - Softbound_Edition_19_en

P. 1070

Proportional

Proportional pressure reducing valve Proportional pressure reducing valve

pressure reducing valves

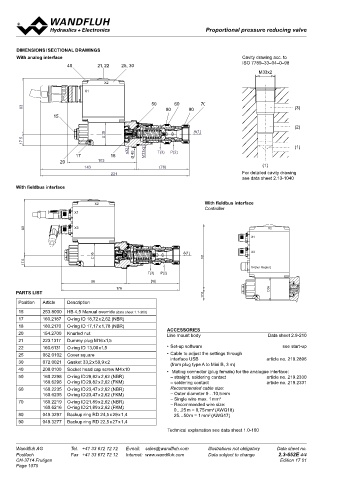

DIMENSIONS / SECTIONAL DRAWINGS Proportional pressure reducing cartridge M33 x 2

With analog interface Cavity drawing acc. to ◆ pilot operated

ISO 7789–33–04–0–98 ◆ Q = 160 l/min ISO 7789

40 21, 22 25, 30 p = 400 bar

max

M33x2 ◆ max x II 2 G Ex db IIC T6, T4

◆ p = 350 bar

N red max x II 2 D Ex tb III C T80 °C, T130 °C

X2 X2

x I M2 Ex db I Mb

X1 X1 Class I Division 1

40 21, 22 25, 30 Class I Zone 1

50 60 70

83 80 90 83 X3 (3)

X2 15 X2 APPLICATION

DESCRIPTION

X1 X1 (2) Pilot operated proportional pressure reducing valve in screw-in These valves are suitable for applications in explosion-hazard

A(1) 35 cartridge construction for cavity according to ISO 7789. Proportio- areas, open cast and also in mines. The electrical remote control in

A(1)

35

83 50 60 90 83 nally to the solenoid current, the solenoid force and the pressure in conjunction with process controls allows economical solutions

17.5 X4(nur Regler) 80 70 X3 17.5

15 (1) port A (1) rise. The valve functions practically independently of the with repeatable processes. The screw-in cartridge is perfectly sui-

s32 M33x2 T(3) P(2) T(3) P(2) pressure in port P (2). Pressure increase in the consumer port A (1) table for installation in control blocks and is installed in sandwich-

17 18 Ø 40

35 20 103 A(1) 35 (1) 98 A(1) 78 to above the adjusted value, e.g. through an active consumer, is (vertical stacked systems) and in flange plates (corresponding data

avoided by discharging excess oil to the tank T (3). With the sole-

sheets in this register). For machining the cartridge cavity in steel

17.5 143 221 17.5 (78) For detailed cavity drawing 176 noid deenergised, the oil flows freely from port P (2) to consumer and aluminum blocks, cavity tools are available (hire or purchase).

M33x2

s32 40 M33x2 T(3) P(2) see data sheet 2.13-1040 port A (1). For the control, Wandfluh proportional amplifiers are Please refer to the data sheets in register 2.13.

s32

40

P(2)

T(3)

17

18

40 21, 22 25, 30 With fieldbus interface available (see register 1.13). The pressure tight encapsulated

20 103

143 78 98 Ex-protection solenoid coil prevents an explosion on the inside

121

X2 221 X2 With fieldbus interface 78 penetrating to the outside as well as an ignitable surface tempera-

A(1) Controller 199 ture.

X1 X1

SYMBOL CERTIFICATES

50 60 70

83 80 90 83 X3 X2 Surface Mining Standard M248

15 X1 (A) 1 -25 °C Electronic

A(1)

P(2) T(3) to…

A(1) A(1) X3

35 Analog 35 101 ATEX x x x x

17.5 17.5 P(2) T(3) X4(nur Regler) (P) 2 (T) 3 IECEx x x x x

s32 M33x2 T(3) P(2) T(3) P(2) CCC x x x x

17 18 Ø 40 EAC x x x x

20 103 98 78

143 (78) 176 35 Australia x x x

221 PARTS LIST 17.5 MA x x x

Position Article Description UL / CSA x x

15 253.8000 HB 4,5 Manual override (data sheet 1.1-300) The certificates can be found on www.wandfluh.com

17 160.2187 O-ring ID 18,72 x 2,62 (NBR)

18 160.2170 O-ring ID 17,17 x 1,78 (NBR) GENERAL SPECIFICATIONS ACTUATION

A(1) ACCESSORIES

20 154.2700 Knurled nut Line mount body Data sheet 2.9-210 Designation Proportional pressure reducing valve Actuation Proportional solenoid, wet pin push

21 223.1317 Dummy plug M16 x1,5 Construction Pilot operated type, pressure tight

22 160.6131 O-ring ID 13,00 x1,5 • Set-up software see start-up Mounting Screw-in cartridge construction Execution MKY45 / 18x60 (data sheet 1.1-183)

25 062.0102 Cover square • Cable to adjust the settings through Nominal size M33 x 2 according to ISO 7789 MKU45 / 18x60 (data sheet 1.1-184)

30 072.0021 Gasket 33,2 x 59,9 x 2 interface USB article no. 219.2896 Connection Cable gland for cable Ø 6,5…14 mm

(from plug type A to Mini B, 3 m)

P(2) T(3) 40 208.0100 Socket head cap screw M4 x10 • Mating connector (plug female) for the analogue interface: Actuation Proportional solenoid

50 160.2298 O-ring ID 29,82 x 2,62 (NBR) – straight, soldering contact article no. 219.2330 Ambient temperature Operation as T6 Attention! The UL execution is always supplied without cable

160.6296 O-ring ID 29,82 x 2,62 (FKM) – soldering contact article no. 219.2331 -25…+40 °C (L9) gland

60 160.2235 O-ring ID 23,47 x 2,62 (NBR) Recommended cable size: Operation as T4

160.6235 O-ring ID 23,47 x 2,62 (FKM) – Outer diameter 9…10,5 mm -25…+90 °C (L9)

70 160.2219 O-ring ID 21,89 x 2,62 (NBR) – Single wire max. 1 mm 2 -25…+70 °C (L15 / L17)

– Recommended wire size:

160.6216 O-ring ID 21,89 x 2,62 (FKM) 0…25 m = 0,75 mm (AWG18) Weight 2,4 kg

2

80 049.3297 Backup ring RD 24,5 x 29 x 1,4 25…50 m = 1 mm (AWG17) MTTFd 150 years

2

90 049.3277 Backup ring RD 22,5 x 27 x 1,4

Technical explanation see data sheet 1.0-100

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.3-652E 4/4 www.wandfluh.com Illustrations are not binding Data subject to change 1/4 Edition: 21 21 2.3-654 E

CH-3714 Frutigen Edition 17 01

Page 1070