Page 1066 - Softbound_Edition_19_en

P. 1066

Proportional

Proportional pressure reducing valve

Proportional pressure reducing valve pressure reducing valves

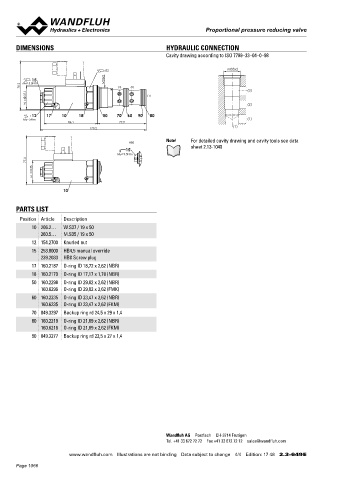

DIMENSIONS HYDRAULIC CONNECTION Proportional pressure reducing valve

Cavity drawing according to ISO 7789–33–04–0–98 Screw-in cartridge construction M33x2

• Integrated amplifier or controller electronics ISO 7789

s32 M33x2 • Pilot operated

15 M33x2 • Q max = 160 l/min

78.2 MD=5.5Nm (3) (2) • p max = 400 bar

37.1 (1) (3) • p N red max = 350 bar

W = (2)

DESCRIPTION FUNCTION APPLICATION

12 17 10 18 50 70 60 90 80

MD=5Nm (1) Pilot operated proportional pressure reducing The proportional pressure reducing valve Proportional pressure reducing valves with

86.1 77.9 valve with integrated electronics as screw-in controls the pressure in port A (1). Proportio- integrated electronics are perfectly suitable for

(1)

170.2 cartridge. Thread M22x1,5 for cavity according nally to the seolenoid current, the solenoid demanding applications in which the pressure

ti ISO 7789. The Plug & Play valves are factory force and the pressure in port A (1) rise. The frequently has to be changed. They are used

Note! For detailed cavity drawing and cavity tools see data set and adjusted and have a high valve-to- valve functions practically independently of the in applications where high valve-to-valve re-

HB0 valve reproducibility. With protection IP67 for pressure in port P (2). The control takes place producibility, easy installation, comfortable ope-

15 sheet 2.13-1040 the electronics, these valves are suitable for- via an analog interface or a fieldbus interface ration and high precision are very important.

MD= 9.5Nm harsh environmental conditions. As standard, (CANopen, J1939 or Profibus DP). The pa- The applications are in the industrial as well as

77.3 4 pressure ranges are available. The adjust- rameterisation takes place by means of the in the mobile hydraulics. The proportional pres-

35 ment takes place by a Wandfluh proportional free of cost parameterisation and diagnostics sure reducing cartridge is perfectly suitable for

M = solenoid (VDE standard 0580). The cartridge software «PASO» or via Feldbus interface. The installation in control blocks as well as in flange

and sandwich valves of the size NG10 (please

USB parameterisation interface is accessible

body as well as the solenoid made of steel

are zinc coated and therefore rust protected. through a cover flap. «PASO» is a Windows refer to separate data sheets in register 2.3).

10 The electronics housing is made of aluminium. programm in the flow diagram style, which For machining the cartridge cavity in steel and

Optionally these valves are available with inte- enables the intuitive adjustment and storing aluminum blocks, cavity tools are available

grated controller. As feedback value generator, of all variable parameters. The data remain (hire or purchase). Please refer to the data

sensors with voltage or current output can be saved in case of a power failure and can also sheets in register 2.13.

PARTS LIST directly connected. The available controller be reproduced and transferred to other DSVs.

structures are optimised for the utilisation with

Position Article Description hydraulic drives.

10 206.2… W.S37 / 19 x 50

260.5… M.S35 / 19 x 50

12 154.2700 Knurled nut TYPE CODE

15 253.8000 HB4,5 manual override M V P PM33 - - / M E - HB4,5 #

239.2033 HB0 Screw plug Pressure reducing valve

17 160.2187 O-ring ID 18,72 x 2,62 (NBR)

Pilot operated

18 160.2170 O-ring ID 17,17 x 1,78 (NBR) Proportional

50 160.2298 O-ring ID 29,82 x 2,62 (NBR)

160.6296 O-ring ID 29,82 x 2,62 (FMK) Screw-in thread M33x2

Nominal pressure range p 100 bar 100

60 160.2235 O-ring ID 23,47 x 2,62 (NBR) N red 200 bar 200

160.6235 O-ring ID 23,47 x 2,62 (FKM) 275 bar 275

70 049.3297 Backup ring rd 24,5 x 29 x 1,4 350 bar 350

80 160.2219 O-ring ID 21,89 x 2,62 (NBR) Nominal voltage U 12 VDC G12

N

160.6216 O-ring ID 21,89 x 2,62 (FKM) 24 VDC G24

90 049.3277 Backup ring rd 22,5 x 27 x 1,4 Slip-on coil Metal housing, square

Connection execution Integrated electronics

Hardware configuration

With analog command value signal (0…+10 V preset) A1

With CANopen according to DSP-408 C1

With Profibus DP in accordance with Fluid Power Technology P1

With CAN J1939 (on request) J1

Function

Amplifier

Controller with current feedback value signal (0...20 mA / 4...20 mA) R1

Controller with voltage feedback value signal (0...10 V) R2

Dichtwerkstoff NBR

FKM (Vitron) D1

Manual override

Design-Index (Subject to change)

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 17 48 2.3-649 E Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.3-652E 1/4

CH-3714 Frutigen Edition 17 01

Page 1066