Page 1155 - Softbound_Edition_19_en

P. 1155

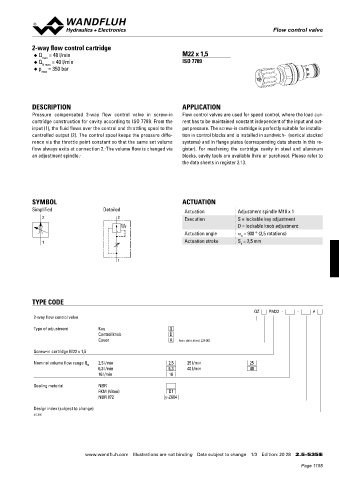

Flow control valves Flow control valve

Flow control valve

CHARACTERISTICS Oil viscosity υ = 30 mm /s 2-way flow control cartridge

2

Q = f (p) Volume flow pressure characteristics ∆p = f (Q) Pressure drop characteristics for return flow ◆ Q = 48 l/min M22 x 1,5

max

(from 2 → 1) ◆ Q = 40 l/min ISO 7789

N max

Q [l/min] p[bar] ◆ p = 350 bar

50 K0784 10 K0783 Q = 40 l/min max

N

40 Q = 40 l/min 8

N

N

30 Q = 25 l/min 6

Q = 16 l/min

N

20 Q = 10 l/min 4 Q = 1 l/min

N

N

Q = 6,3 l/min

N

10 Q = 4 l/min 2 DESCRIPTION APPLICATION

N

Q = 1; 1,6;

N

0 2,5 l/min 0 Pressure compensated 2-way flow control valve in screw-in Flow control valves are used for speed control, where the load cur-

0 50 100 150 200 250 300 350 p [bar] 0 10 20 30 40 50 Q [l/min] cartridge construction for cavity according to ISO 7789. From the rent has to be maintained constant independent of the input and out-

input (1), the fluid flows over the control and throttling spool to the put pressure. The screw-in cartridge is perfectly suitable for installa-

controlled output (2). The control spool keeps the pressure diffe- tion in control blocks and is installed in sandwich- (vertical stacked

DIMENSIONS / SECTIONAL DRAWINGS rence via the throttle point constant so that the same set volume systems) and in flange plates (corresponding data sheets in this re-

flow always exits at connection 2. The volume flow is changed via gister). For machining the cartridge cavity in steel and aluminum

Screw setting versions „S“

an adjustment spindle. blocks, cavity tools are available (hire or purchase). Please refer to

Cavity drawing according to

Ø 17 ISO 7789–22–01–0–98 the data sheets in register 2.13.

20

s4 M22x1,5

30

s13

SYMBOL ACTUATION

41 (2) Simplified Detailed Actuation Adjustment spindle M10 x 1

s27

2 2 Execution S = lockable key adjustment

ø 30 (1) D = lockable knob adjustment

79

40 Actuation angle a = 900 ° (2,5 rotations)

b

M22x1,5 (1) Actuation stroke S = 2,5 mm

1 b

38 For detailed cavity drawing

and cavity tools see data

60 sheet 2.13-1008. 1

50

TYPE CODE

PARTS LIST ACCESSORIES QZ PM22 - - #

Line mount body Data sheet 2.9-205 2-way flow control valve

Position Article Description

20 193.1050 Retainer for shaft RD5 DIN 6799 Type of adjustment Key S

30 153.1403 Hexagonal nut 0,5D M8 Control knob D

A

Cover

40 160.2188 O-ring ID 18,77x1,78 (see data sheet 2.0-50)

50 160.2156 O-ring ID 15,60x1,78 Screw-in cartridge M22 x 1,5

2

1

60 049.3196 Back-up ring RD 16,1x19x1,4

1 2 Technical explanation see data sheet 1.0-100 Nominal volume flow range Q 2,5 l/min 2,5 25 l/min 25

N 6,3 l/min 6,3 40 l/min 40

16 l/min 16

Sealing material NBR

FKM (Viton) D1

NBR 872 y-Z604

Design index (subject to change)

2.5-535

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.5-530E 2/2 www.wandfluh.com Illustrations are not binding Data subject to change 1/3 Edition: 20 28 2.5-535 E

CH-3714 Frutigen Edition 05 06

Page 1155