Page 1002 - Softbound_Edition_19_en

P. 1002

Proportional pressure relief valve

Proportional pressure relief valve Proportional pressure relief valve

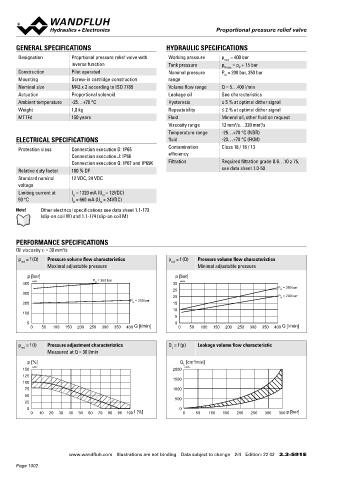

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS DIMENSIONS HYDRAULIC CONNECTION

Designation Proprtional pressure relief valve with Working pressure p = 400 bar Cavity drawing according to ISO 7789–42–02–0–07

max

inverse function Tank pressure p T max = p + 15 bar

P

Construction Pilot operated Nominal pressure P = 200 bar, 350 bar s41 M42x2

N

Mounting Screw-in cartridge construction range * 15 M42x2 (2)

MD=10Nm

Nominal size M42 x 2 according to ISO 7789 Volume flow range Q = 5…400 l/min 81.7 (2)

Actuation Proportional solenoid Leakage oil See characteristics 37.1 s6 (1)

Ambient temperature -25…+70 °C Hysteresis ≤ 5 % at optimal dither signal W = E X

Weight 1,0 kg Repeatability ≤ 2 % at optimal dither signal (1)

12

MTTFd 150 years Fluid Mineral oil, other fluid on request MD=5Nm 17 10 18 50 70 60

Viscosity range 12 mm /s…320 mm /s 34.7 85.8 56.7 (1)

2

2

177.2

Temperature range -25…+70 °C (NBR)

ELECTRICAL SPECIFICATIONS fluid -20…+70 °C (FKM) Note! For detailed cavity drawing and cavity tools see data

sheet 2.13-1048

Protection class Connection execution D: IP65 Contamination Class 18 / 16 / 13

Connection execution J: IP66 efficiency

Connection execution G: IP67 and IP69K Filtration Required filtration grade ß 6…10 ≥ 75, 80.8 X

Relative duty factor 100 % DF see data sheet 1.0-50 35

Standard nominal 12 VDC, 24 VDC M =

voltage

Limiting current at I = 1320 mA (U = 12VDC) 10

N

G

50 °C I = 660 mA (U = 24VDC)

G N E = Air bleed screw

Note! Other electrical specifications see data sheet 1.1-173 *Adjustment screw for adjusting the nominal pressure

(slip-on coil W) and 1.1-174 (slip-on coil M)

PERFORMANCE SPECIFICATIONS PARTS LIST COMMISSIONING

2

Oil viscosity u = 30 mm /s When commissioning, the valve must be vented under pressure as

Position Article Description

p = f (Q) Pressure volume flow characteristics p = f (Q) Pressure volume flow characteristics follows (see detail X in Dimensions):

red red 10 206.2… W.S37 / 19 x 50

Maximal adjustable pressure Minimal adjustable pressure

260.5… M.S35 / 19 x 50 Loosen lock nut

p [bar] p [bar] 12 154.2700 Knurled nut ◆ Remove screw (E)

400 K4272 P N = 350 bar 30 K4273 17 160.2187 O-ring ID 18,72 x 2,62 (NBR) ◆ Push the non-return valve (with pin or hex key < 1,3 mm)

25 P N = 350 bar ◆

300 18 160.2170 O-ring ID 17,17 x 1,78 (NBR) ◆ Screw-in the screw (E)

20 P N = 200 bar

P N = 200 bar ◆ Adjust the required pressure and tighten the lock nut

200 15 50 160.2377 O-ring ID 37,77 x 2,62 (NBR)

10 160.6379 O-ring ID 37,77 x 2,62 (FKM)

100

5 60 160.2314 O-ring ID 31,42 x 2,62 (NBR) Therewith oil flows out with the corresponding

0 0 160.6315 O-ring ID 31,42 x 2,62 (FKM) Attention!

0 50 100 150 200 250 300 350 400 Q [l/min] 0 50 100 150 200 250 300 350 400 Q [l/min] pressure! Cover with a cloth.

70 049.8364 Backup ring PTSM rd 29,1 x 33,6 x 1 ,4

p = f (I) Pressure adjustment characteristics Q = f (p) Leakage volume flow characteristic

red L

Measured at Q = 30 l/min STANDARDS INSTALLATION NOTES

p [%] Q [cm /min] Cartridge cavity ISO 7789 Mounting type Screw-in cartridge M42 x 2

3

L

150 K4273 2000 K4275 Solenoids DIN VDE 0580 Mounting position Any, preferably horizontal

125

1500 Connection execution D EN 175301 – 803 Tightening torque M = 280 Nm Screw-in cartridge

100 M = 5 Nm knurled nut

D

75 1000 Protection class EN 60 529 D

50 Contamination efficiency ISO 4406

25 500

0 0

0 10 20 30 40 50 60 70 80 90 100 I [%] 0 50 100 150 200 250 300 350 p [bar]

www.wandfluh.com Illustrations are not binding Data subject to change 2/4 Edition: 22 02 2.3-591 E www.wandfluh.com Illustrations are not binding Data subject to change 3/4 Edition: 22 02 2.3-591 E

Page 1002