Page 1006 - Softbound_Edition_19_en

P. 1006

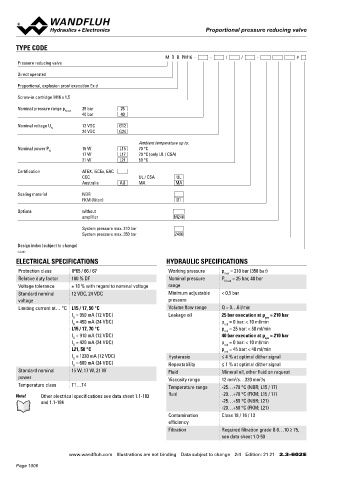

Proportional pressure reducing valve

Proportional pressure reducing valve Proportional pressure reducing valve

TYPE CODE PERFORMANCE SPECIFICATIONS

2

M D B PM16 - - / / - # Oil viscosity u = 30 mm /s

Pressure reducing valve p = f (Q) Pressure volume flow characteristics p = f (Q) Pressure volume flow characteristics

red

red

Direct operated Maximal adjustable pressure Maximal adjustable pressure

25 bar execution 40 bar execution

Proportional, explosion proof execution Ex d *Limit of the operating range *Limit of the operating range

p [bar] p [bar]

Screw-in cartridge M16 x 1,5

30 K1145 60 K1144

Nominal pressure range p N red 25 bar 25

40 bar 40 20 40

Nominal voltage U 12 VDC G12 ∗ ∗

N 10 20

24 VDC G24

Ambient temperature up to: 0 0

Nominal power P 15 W L15 70 °C 6 4 2 0 2 4 6 6 4 2 0 2 4 6

N

17 W L17 70 °C (only UL / CSA) A T Q [l/min] P A A T Q [l/min] P A

21 W L21 50 °C

Certification ATEX, IECEx, EAC

CCC UL / CSA UL p = f (n) Pressure adjustment characteristics p = f (n) Pressure adjustment characteristics

Australia AU MA MA red red

Measured at Q = 0 l/min (static) Measured at Q = 0 l/min (static)

Sealing material NBR 25 bar execution 40 bar execution

FKM (Viton) D1 **Slightly increased hysteresis **Slightly increased hysteresis

p [bar] p [bar]

Options without 30 K4148 L21 50 K4149 L21

amplifier M248

25 40

System pressure max. 210 bar 20 L15 / L17 30 L15 / L17

System pressure max. 350 bar Z406 15

10 20

Design index (subject to change) 5 10

2.3-602 ** **

0 0

ELECTRICAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS 0 10 20 30 40 50 60 70 80 90 100 l [%] 0 10 20 30 40 50 60 70 80 90 100 l [%]

Protection class IP65 / 66 / 67 Working pressure p = 210 bar (350 bar)

max

Relative duty factor 100 % DF Nominal pressure P = 25 bar, 40 bar

N red

Voltage tolerance ± 10 % with regard to nominal voltage range

Standard nominal 12 VDC, 24 VDC Minimum adjustable < 0,5 bar STANDARDS SURFACE TREATMENT

voltage pressure Cartridge cavity Wandfluh standard ◆ The cartridge body is gas-nitro carburised

Limiting current at… °C L15 / 17, 50 °C Volume flow range Q = 0…6 l/min Explosion protection Directive 2014 / 34 / EU (ATEX) ◆ The slip-on coil and the armature tube are zinc-nickel coated

I = 950 mA (12 VDC) Leakage oil 25 bar execution at p = 210 bar Flameproof enclosure EN / IEC / UL 60079-1, 31

sys

G

I = 450 mA (24 VDC) p = 0 bar: < 10 ml/min

G red Cable entry EN 60079-0, 1, 7, 15, 31

L15 / 17, 70 °C p = 25 bar: < 50 ml/min Protection class EN 60 529

red

I = 910 mA (12 VDC) 40 bar execution at p = 210 bar Contamination ISO 4406

G

sys

I = 420 mA (24 VDC) p = 0 bar: < 10 ml/min

G red efficiency

L21, 50 °C p = 45 bar: < 40 ml/min

red

I = 1230 mA (12 VDC) Hysteresis ≤ 4 % at optimal dither signal

G

I = 600 mA (24 VDC)

G Repeatability ≤ 1 % at optimal dither signal COMMISSIONING INSTALLATION NOTES

Standard nominal 15 W, 17 W, 21 W Fluid Mineral oil, other fluid on request

power Viscosity range 12 mm /s…320 mm /s Attention! The solenoid coil must only be put into operation, if the Mounting type Screw-in cartridge type M16 x 1,5

2

2

Temperature class T1…T4 Temperature range -25…+70 °C (NBR; L15 / 17) requirements of the operating instructions supplied are Mounting position Any, preferably horizontal

observed to their full extent. In case of non-observance,

Note! Other electrical specifications see data sheet 1.1-183 fluid -20…+70 °C (FKM; L15 / 17) no liability can be assumed. Tightening torque M = 30 Nm screw-in cartridge

D

M = 9 Nm Knurled nut

and 1.1-184 -25…+50 °C (NBR; L21) D

-20…+50 °C (FKM; L21)

Contamination Class 18 / 16 / 13

efficiency

Filtration Required filtration grade ß 6…10 ≥ 75,

see data sheet 1.0-50

www.wandfluh.com Illustrations are not binding Data subject to change 2/4 Edition: 21 21 2.3-602 E www.wandfluh.com Illustrations are not binding Data subject to change 3/4 Edition: 21 21 2.3-602 E

Page 1006