CERTIFICATES

Our coils are certified for applications in zones with explosion-hazard gas, steam, vapour, air and dust mixtures of the zones 1/21 and 2/22

Flammable gases, vapours and dust can form an explosive atmosphere when mixed with oxygen. In order to ensure a high level of safety, appropriate protective regulations exist for the various operating equipment to avoid the risk of explosion hazards. The solenoid as an electrical actuation in the valve technology must therefore demonstrate a type of protection that is in line with the explosion protection standard.

An explosion is usually a sudden, rapid oxidation or decomposition reaction of flammable gases, vapours or dusts with the oxygen in the surrounding air. For an explosion to occur, the following 3 factors must normally come together.

Potentially explosive atmospheres can form in production and work areas when the first two conditions for an explosion are met. Typical potentially explosive atmospheres are found in mines, refineries, chemical factories, paint shops, cleaning plants, mills and stores for ground materials and other combustible dusts, in tank and loading facilities for flammable gases, liquids and solids. The first two factors - flammable substance and air - must be present in a certain quantitative ratio for them to form an explosive atmosphere. To prevent explosions in such areas, all possible sources of ignition must be consistently prevented. On the one hand, people with their activities and electrical discharges are one of the major hazards in these areas; on the other hand, it is the technical equipment that is supplied with electricity and can spread heat or even sparks in the event of a defect. In the case of hydraulic valves, it is primarily the solenoid coils that can pose a corresponding hazard. In the design and manufacture of such explosion-protected valve solenoids, we know of two different constructive explosion protection types that are used.

Type of protection for products which contain parts inside their enclosure which can ignite an explosive atmosphere. Such products must have a suitable enclosure which, on the one hand, withstands the explosion pressure of an internal enclosure explosion and, on the other hand, ensures that the explosion is prevented from spreading to the explosive atmosphere surrounding the enclosure. Technically required gaps are designed to be long and narrow enough to ensure that escaping hot gases outside the enclosure have lost their ignition capability or, if gaps are only required for the manufacturing process, are hermetically sealed.

Solenoid coil in accordance with Directive 2014/34/EU (ATEX) for potentially explosive atmospheres. The flameproof enclosure (according to EN/IEC 60079-1/31) prevents internal explosion from explosion inside to outside. The design prevents an ignitable surface temperature.

|

|

Intrinsically safe equipment contains only electronic circuits that meet the requirements for intrinsically safe circuits. These are circuits in which, under the test conditions specified in the standard, no spark or thermal effect can cause the ignition of a potentially explosive atmosphere of subgroups IIA, IIB or IIC or a dust-air mixture of group III. The test conditions include normal operation and certain fault conditions specified in the standard.

The solenoid coil for explosion hazard areas in the ignition protection type «intrinsically safe» is utilised on solenoid spool valves. The winding resistance can be adapted to the intrinsically safe electric power supply utilised, in the range of 20...1000 Ω. With 100 Ω or 152 Ω coil resistance, it is adapted to the recommended electric power supplies. Three diodes connected in parallel with the winding serve to render the inductivity ineffective, and a diode connected in series serves as a protection against reverse polarity

|

|

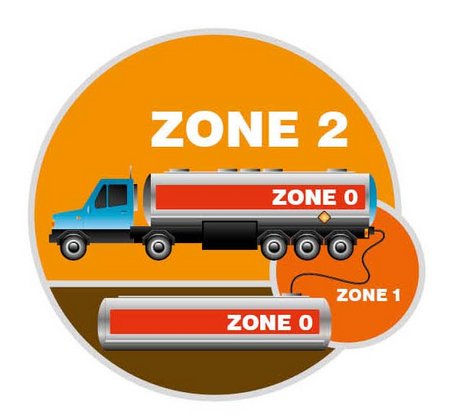

When classifying potentially explosive atmospheres, the zones and atmospheres are evaluated and classified according to their hazard potential. The following six explosion protection zones are distinguished:

Zone 0

A place in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapour or mist is present continuously or for long periods.

Zone 1

A place in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapour or mist is likely to occur in normal operation.

Zone 2

A place in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Zone 0

A place in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapour or mist is present continuously or for long periods.

Zone 1

A place in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapour or mist is likely to occur in normal operation.

Zone 2

A place in which an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapour or mist is not likely to occur in normal operation but, if it does occur, will persist for a short period only.

Technical measures must be taken to ensure that no ignition source can act in accordance with the classification of an assumed explosive mixture (gap width, temperature class). There are several technical ways to achieve explosion protection of an electrical appliance. The ignition protection types are listed in the table. In the Ex marking of a device, the type of protection is indicated by the first letter of the type of protection.

| Ignition protection | Description | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| t | Protection by housing | Type of protection only for dust Explosion protection. The enclosure is securely sealed against the ingress of dust. This requires a enclosure tightness according to IEC/EN 60529 of IP6x. In addition, surfaces exposed to dust must not exceed a certain temperature. | |||||||||

| d | Flameproof enclosure | The components that can trigger an ignition are installed in an enclosure that can withstand the explosion pressure. The openings of the enclosure are such that transmission of the explosion to the outside is prevented. | |||||||||

| i | Intrinsic safety | The electrical equipment is supplied via a safety barrier which limits the current and voltage so that the minimum ignition energy and ignition temperature of an explosive mixture is not reached. The equipment is further subdivided into Ex-ia for Ex zone 0 or 1 and Ex-ib for Ex zone 1 or 2. | |||||||||

Our coils are certified for applications in zones with explosion-hazard gas, steam, vapour, air and dust mixtures of the zones 1/21 and 2/22

Im Bereich des Bergbaus werden Hydrauliksysteme für verschiedenartige Aufgaben eingesetzt. Diese Einsatzgebiete sind prädestiniert für xplosionsgefährdeten Atmosphären wie Stäube, brennbare Flüssigkeiten oder Gase. Um Explosionen zu vermeiden, steht daher meist eine explosionsgeschützte Technik im Einsatz. Dies ist wichtig, da eine Explosion, insbesondere im Umtertagebau verheerende Personen- und Materialschäden, bis hin zum Einsturz der Mine zur Folge hätte.

Im Bereich des Bergbaus werden Hydrauliksysteme für verschiedenartige Aufgaben eingesetzt. Diese Einsatzgebiete sind prädestiniert für xplosionsgefährdeten Atmosphären wie Stäube, brennbare Flüssigkeiten oder Gase. Um Explosionen zu vermeiden, steht daher meist eine explosionsgeschützte Technik im Einsatz. Dies ist wichtig, da eine Explosion, insbesondere im Umtertagebau verheerende Personen- und Materialschäden, bis hin zum Einsturz der Mine zur Folge hätte.

Harbour facility

Offshore

Mines and opencast mines

Chemical plants

Depending on the area of application, a particularly robust and proven technology is required that meets the high demands on corrosion protection. The valves are made of rust- and acid-resistant steel and are used in particular in mining and open-cast mining, on the high seas, in port facilities or in mobile machinery. For this purpose, valves are available in various designs and with different functions.