Page 860 - Softbound_Edition_19_en

P. 860

Pressure relief valve

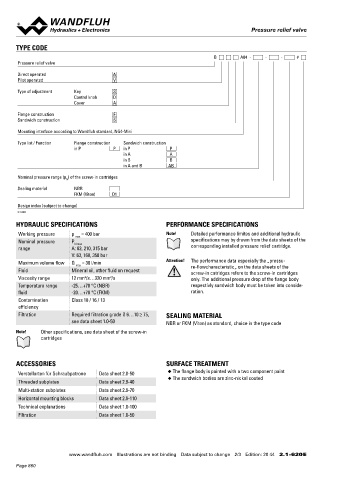

Pressure relief valve Pressure relief valve

TYPE CODE VALVES INSTALLED

B A04 - - - # The following screw-in cartridges are used in either the flange body or the sandwich body.

Pressure relief valve Article Description Data sheet no.

Direct operated A BV.PM22 Pressure relief cartridge pilot operated 2.1-530

Pilot operated V BA.PM22 Pressure relief cartridge direct operated 2.1-540

Type of adjustment Key S

Control knob D DIMENSIONS

Cover A Flange execution Sandwich execution

B.DFA04-P B.DSA04-P

Flange construction F 45 39.5

Sandwich construction S 6 39

9.5 5.5

P

Mounting interface according to Wandfluh standard, NG4-Mini P A B

A B 40 23 T To 40

Type list / Function Flange construction Sandwich construction 19 T To 21

in P P in P P 20 10 20 MD=18Nm

in A A 27 10 20 MD=18Nm 63

48

in B B 80 5 95 5

in A and B AB

Nominal pressure range (p ) of the screw-in cartridges

N Sandwich execution Type of adjustment Type of adjustment

Sealing material NBR B.DSA04-A / B / AB B.S.A04 B.A.A04

FKM (Viton) D1 P

A B

Design index (subject to change) 40

T To s4

2.1-620

MD=60Nm

10 45.6 MD=60Nm

HYDRAULIC SPECIFICATIONS PERFORMANCE SPECIFICATIONS AB 125 53.2

B-Seitig 108.2

Working pressure p = 400 bar Note! Detailed performance limites and additional hydraulic A-Seitig108.2

max

Nominal pressure P N max specifications may by drawn from the data sheets of the B.DSA04-A: Cartridge on A side

range A: 63, 210, 315 bar corresponding installed pressure relief cartridge. B.DSA04-B: Cartridge on B side

V: 63, 160, 350 bar B.DSA04-AB: Cartridge on A and B side

Maximum volume flow Q = 30 l/min Attention! The performance data especially the „pressu-

max re-flowcharacteristic„ on the data sheets of the HYDRAULIC CONNECTION PARTS LIST

Fluid Mineral oil, other fluid on request screw-in catridges refere to the screw-in cartridges

2

Viscosity range 12 mm /s…320 mm /s only. The additional pressure drop of the flange body 28 Position Article Description

2

Temperature range -25…+70 °C (NBR) respectivly sandwich body must be taken into conside- 14 10 160.2052 O-ring ID 5,28 x 1,78 (NBR)

fluid -20…+70 °C (FKM) ration. 160.6052 O-ring ID 5,28 x 1,78 (FKM)

Contamination Class 18 / 16 / 13 P 20 238.2406 Screw plug VSTI G1/4"-ED

efficiency

A B

Filtration Required filtration grade ß 6…10 ≥ 75, SEALING MATERIAL 14 27

see data sheet 1.0-50 NBR or FKM (Viton) as standard, choice in the type code T T0

Note! Other specifications, see data sheet of the screw-in

cartridges

STANDARDS INSTALLATION NOTES

ACCESSORIES SURFACE TREATMENT Mounting interface Wandfluh standard Mounting type Flange or sandwich mounting

Verstellarten für Schraubpatrone Data sheet 2.0-50 ◆ The flange body is painted with a two component paint Contamination ISO 4406 3 fixing holes for

socket head screws or studs M5

◆ The sandwich bodies are zinc-nickel coated efficiency

Threaded subplates Data sheet 2.9-40 Mounting position Any, preferably horizontal

Multi-station subplates Data sheet 2.9-70 Tightening torque Fixing screws M = 5,2 Nm (quality 8.8,

Horizontal mounting blocks Data sheet 2.9-110 zinc coated) D

Technical explanations Data sheet 1.0-100 Screw-in cartridge M = 60 Nm

D

Filtration Data sheet 1.0-50

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

www.wandfluh.com Illustrations are not binding Data subject to change 2/3 Edition: 20 44 2.1-620 E www.wandfluh.com Illustrations are not binding Data subject to change 3/3 Edition: 20 44 2.1-620 E

Page 860