Page 863 - Softbound_Edition_19_en

P. 863

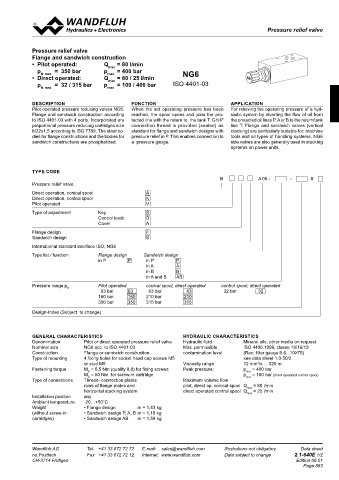

Pressure relief valve

Pressure relief valves

Pressure relief valve

Flange and sandwich construction

• Pilot operated: Q max = 80 l/min

p = 350 bar p max = 400 bar NG6

N max

• Direct operated: Q max = 80 / 25 l/min

p = 32 / 315 bar p = 100 / 400 bar ISO 4401-03

N max max

DESCRIPTION FUNCTION APPLICATION

Pilot operated pressure reducing valves NG6. When the set operating pressure has been For relieving the operating pressure of a hyd-

Flange and sandwich construction according reached, the spool opens and joins the pro- raulic system by diverting the flow of oil from

to ISO 4401-03 with 4 ports. Incorporated are tected line with the return to the tank T. G1/4" the protected oil lines P, A or B to the return/tank

proportional pressure reducing cartridges size connection thread is provided (sealed) as line T. Flange and sandwich valves (vertical

M22x1,5 according to ISO 7789. The steel bo- standard for flange and sandwich designs with stacking) are particularly suitable for: machine

dies for flange constructions and the bodies for pressure relief in P. This enables connection to tools and all types of handling systems. NG6

sandwich constructions are phosphatized. a pressure gauge. size valves are also generally used in stacking

systems on power units.

TYPE CODE

B A 06 - - #

Pressure relief valve

Direct operation, conical spool A

Direct operation, control spool K

Pilot operated V

Type of adjustment Key S

Control knob D

Cover A

Flange design F

Sandwich design S

International standard interface ISO, NG6

Type list / function Flange design Sandwich design

in P P in P P

in A A

in B B

in A and B AB

Pressure range p Pilot operated conical spool, direct operated control spool, direct operated

N

63 bar 63 63 bar 63 32 bar 32

160 bar 160 210 bar 210

350 bar 350 315 bar 315

Design-Index (Subject to change)

GENERAL CHARACTERISTICS HYDRAULIC CHARACTERISTICS

Denomination Pilot or direct operated pressure relief valve Hydraulic fluid Mineral oils, other media on request

Nominal size NG6 acc. to ISO 4401-03 Max. permissible ISO 4406:1999, classe 18/16/13

Construction Flange or sandwich construction contamination level (Rec. filter gauge ß 6...10≥75)

Type of mounting 4 fixing holes for socket head cap screws M5 see data sheet 1.0-50/2

or stud M5 Viscosity range 12 mm /s ... 320 m

2

Fastening torque M = 5,5 Nm (quality 8.8) for fixing screws Peak pressure: p max = 400 bar

D

M = 50 Nm for screw-in cartridge p max = 100 bar (direct operated control spool)

D

Type of connections Thread- connection plates Maximum volume flow

rows of flange plates and pilot, direct op. conical spool Q max = 80 l/min

horizontal stacking system direct operated control spool Q max = 25 l/min

Installation position any

Ambient temperature -20…+50°C

Weight • Flange design m = 1,43 kg

(without screw-in- • Sandwich design P, A, B m = 1,18 kg

cartridges) • Sandwich design AB m = 1,58 kg

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet

no.Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.1-640E 1/2

CH-3714 Frutigen Edition 06 51

Page 863