Page 864 - Softbound_Edition_19_en

P. 864

30

20

41

30

15

41

30

20

22

22

A

B

45

A

B

45

A

B

G1/4"

45

G1/4"

12

68

40

12

36

52

104

36

40

12 22 52 40 5,5 Æ 5,5 Æ 5,5 10 18 18 18 G1/4" 36 P P P T T T 104 68 10 ∗ 17,5 17,5 17,5 22,5 22,5 22,5 20

68

52 104

T

T

A B

Pressure relief valve

A B Pressure relief valves Pressure relief valves

P ∗

P

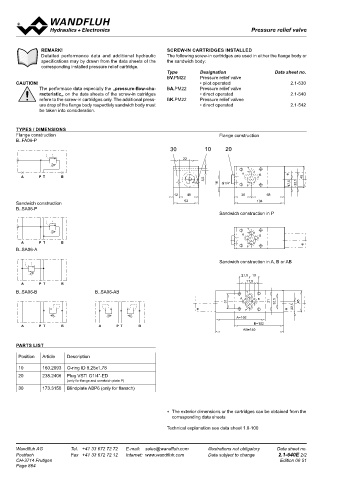

REMARK! SCREW-IN CARTRIDGES INSTALLED Pressure relief valve

Detailed performance data and additional hydraulic The following screw-in cartridges are used in either the flange body or Flange and sandwich construction

19

specifications may by drawn from the data sheets of the 21,5 the sandwich body:

19

21,5

corresponding installed pressure relief cartridge. 17,8 • Pilot operated: Q max = 100 l/min

21,5 17,8 19 Designation Data sheet no. p max = 350 bar p = 400 bar NG10

Type

N

T 17,8 Pressure relief valve • Direct operated: Q max = 100 / 25 l/min

BV.PM22

T max

CAUTION! A B • pilot operated 2.1-530 p max = 32 / 315 bar p = 100 / 400 bar ISO 4401-05

31

45

B

The performace data especially the „pressure-flow-cha- A T BA.PM22 21 21 32,5 32,5 Pressure relief valve N max

45

31

22,5

22,5

racteristic„ on the data sheets of the screw-in catridges A P B 21 • direct operated 2.1-540

31

45

refere to the screw-in cartridges only. The additional press- P BK.PM22 32,5 Pressure relief valvee

22,5

ure drop of the flange body respectivly sandwich body must A=102 P∗ A=102 • direct operated 2.1-542 DESCRIPTION FUNCTION APPLICATION

∗

be taken into consideration. B=102 Pilot operated pressure reducing valves NG10. When the set operating pressure has been For relieving the operating pressure of a hyd-

B=102

A=102 Flange and sandwich construction according reached, the spool opens and joins the pro- raulic system by diverting the flow of oil from the

AB=140

AB=140 B=102 to ISO 4401-05 with 4 ports. Incorporated are tected line with the return to the tank T. G1/4" protected oil lines P, A or B to the return / tank

AB=140 proportional pressure reducing cartridges size connection thread is provided (sealed) as line T. Flange and sandwich valves (vertical

TYPES / DIMENSIONS M22x1,5 according to ISO 7789. The steel bo- standard for flange and sandwich designs with stacking) are particularly suitable for: machine

Flange construction Flange construction dies for flange constructions and the bodies for pressure relief in P. This enables connection to tools and all types of handling systems. NG10

B..FA06-P sandwich constructions are phosphatized. a pressure gauge. size valves are also generally used in stacking

30 10 20 systems on power units.

15 30 41 10 20

22 30 41 20

22

22 T TYPE CODE

A T B ∗

A P T B A B 45

5,5 T 45 B A 10 - - #

Æ 5,5 18 18 G1/4" A P B 17,5 17,5 22,5 22,5 Pressure relief valve

G1/4"

Æ 5,5 P 45 Direct operation, conical spool A

12 40 18 G1/4" 36 P 68 17,5 22,5

12 40 36 68 Direct operation, conical spool K

Sandwich construction 52 40 104 68 Pilot operated V

52

104

B..SA06-P 12 36

52 Sandwich construction in P Type of adjustment Key S

104

Control knob D

Cover A

T

T

A B Flange design F

A B Sandwich design S

A P T B P ∗

P International standard interface ISO, NG10

B..SA06-A

Type list / function Flange design Sandwich design

Sandwich construction in A, B or AB in P P in P P

21,5 19 in A A

21,5 19

17,8 in B B

21,5 17,8 19 in A and B AB

T 17,8

A P T B T

A B Pressure range p Pilot operated conical spool, direct operated control spool, direct operated

N

B..SA06-B B..SA06-AB 31 A T B 21 32,5 45 63 bar 63 63 bar 63 32 bar 32

31 21 32,5 22,5 45 160 bar 160 210 bar 210

A P B 22,5

31 P 21 32,5 45 350 bar 350 315 bar 315

∗ A=102 ∗ 22,5

A=102 P

B=102 Design-Index (Subject to change)

A=102 B=102

AB=140

AB=140 B=102

A P T B A P T B

AB=140

GENERAL CHARACTERISTICS HYDRAULIC CHARACTERISTICS

PARTS LIST Denomination Pilot or direct operated pressure relief valve Hydraulic fluid Mineral oils, other media on request

Nominal size NG10 acc. to ISO 4401-05 Max. permissible ISO 4406:1999, classe 18/16/13

Position Article Description Construction Flange or sandwich construction contamination level (Rec. filter gauge ß 6...10≥75)

Type of mounting 4 fixing holes for socket head cap screws M6 see data sheet 1.0-50/2

2

10 160.2093 O-ring ID 9,25x1,78 or stud M6 Viscosity range 12 mm /s ... 320 m

20 238.2406 Plug VSTI G1/4“-ED Fastening torque M = 9,5 Nm (quality 8.8) for fixing screws Peak pressure: p p max = 400 bar

D

M = 50 Nm for screw-in cartridge

= 100 bar (direct operated control spool)

D

A

(only for flange and sandwich plate P) P T B Type of connections Thread- connection plates Maximum volume flow max

30 173.3150 Blindplate ABP6 (only for flansch) rows of flange plates and pilot, direct op. conical spool Q max = 100 l/min

horizontal stacking system direct op. control spool Q max = 25 l/min

Installation position any

Ambient temperature -20…+50 °C

∗ The exterior dimensions or the cartridges can be obtained from the Weight • Flange design m = 2,34 kg

corresponding data sheets (without screw-in- • Sandwich design P, A, B m = 1,70 kg

cartridges) • Sandwich design AB m = 1,94 kg

Technical explanation see data sheet 1.0-100

A

Wandfluh AG Tel. +41 33 672 72 72 P T B Illustrations not obligatory Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet

E-mail: sales@wandfluh.com

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.1-640E 2/2 no.Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.1-660E 1/2

CH-3714 Frutigen Edition 06 51 CH-3714 Frutigen Edition 08 48

Page 864

A P T B

A P T B A P T B