Page 843 - Softbound_Edition_19_en

P. 843

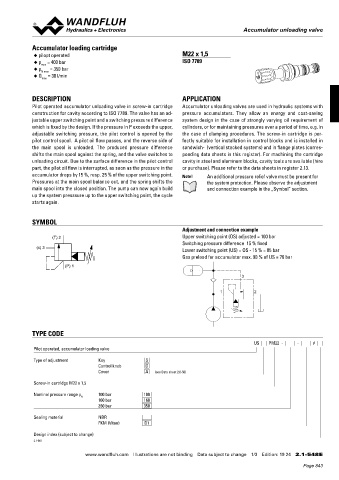

Accumulator loading valve

Pressure sequence valves Accumulator unloading valve

chaRacteRistics Oil viscosity υ = 30 mm /s Accumulator loading cartridge

2

p = f (Q) Pressure volume flow characteristics p = f (Q) Pressure volume flow characteristics ◆ pilopt operated M22 x 1,5

(Maximal adjustable pressure) (Minimal adjustable pressure) ◆ p = 400 bar ISO 7789

p [bar] p [bar] ◆ p max = 350 bar

400 K0102 P N = 350 bar 40 K0112 N max

◆ Q = 30 l/min

max

P N = 160/350 bar

300 30

200 P N = 160 bar 20 P N = 63 bar

DESCRIPTION APPLICATION

100 P N = 63 bar 10 Pilot operated accumulator unloading valve in screw-in cartridge Accumulator unloading valves are used in hydraulic systems with

0 0 construction for cavity according to ISO 7789. The valve has an ad- pressure accumulators. They allow an energy and cost-saving

0 25 50 75 100 Q [l/min] 0 25 50 75 100 Q [l/min] justable upper switching point and a switching pressure difference system design in the case of strongly varying oil requirement of

p = f (n) Pressure adjustment characteristics Q = f (p) Leakage volume flow characteristics which is fixed by the design. If the pressure in P exceeds the upper, cylinders, or for maintaining pressures over a period of time, e.g. in

L

(at Q = 5 l/min) [P (1) → T (2)] adjustable switching pressure, the pilot control is opened by the the case of clamping procedures. The screw-in cartridge is per-

p [bar] Q [cm /min] pilot control spool. A pilot oil flow passes, and the reverse side of fectly suitable for installation in control blocks and is installed in

3

400 K0113 200 K0114

P N = 350 bar the main spool is unloaded. The produced pressure difference sandwich- (vertical stacked systems) and in flange plates (corres-

300 150 shifts the main spool against the spring, and the valve switches to ponding data sheets in this register). For machining the cartridge

200 P(1) 100 unloading circuit. Due to the surface difference in the pilot control cavity in steel and aluminum blocks, cavity tools are available (hire

P N = 160 bar part, the pilot oil flow is interrupted, as soon as the pressure in the or purchase). Please refer to the data sheets in register 2.13.

100 50 accumulator drops by 15 %, resp. 25 % of the upper switching point.

P N = 63 bar Note! An additional pressure relief valve must be present for

0 0 Pressures at the main spool balance out, and the spring shifts the the system protection. Please observe the adjustment

2

0 x(3) 1 A(2) 3 4 5 n [-] 0 50 100 150 200 250 300 350 p [bar] main spool into the closed position. The pump can now again build and connection example in the „Symbol” section.

up the system presssure up to the upper switching point, the cycle

DiMensions starts again.

Screw adjustment „S“ Knob adjustment „D“ Cavity drawing acc. to

ISO 7789–22–06–0–98

ø 26

Ø 17 M22x1,5

s4 30 20 SYMBOL

40 Adjustment and connection example

(T) 2 Upper switching point (OS) adjusted = 100 bar

s13 Switching pressure difference 15 % fixed

40,6 48,1 (x) 3 Lower switching point (US) = OS - 15 % = 85 bar

s27 (3) Gas preload for accumulator max. 90 % of US = 76 bar

ø30

50

M22x1,5 (P) 1

65 (2) 3

54 75

(1) 1 2

60

70

(1)

For detailed cavity drawing and avity

tools see data sheet 2.13-1006.

TYPE CODE

US PM22 - - #

PaRts list accessoRies Pilot operated, accumulator loading valve

Sandwich plate NG4-Mini Data sheet 2.1-820

Position Article Description Sandwich plate NG6 Data sheet 2.1-840 Type of adjustment Key S

Sandwich plate NG10 Data sheet 2.1-860 Control knob D

20 114.2224 Knob Cover A (see Data sheet 2.0-50)

30 193.1061 Safety plate RD6 DIN 6799

40 153.1402 Hexagonal nut 0,5D M8x1 Screw-in cartridge M22 x 1,5

50 160.2188 O-ring ID 18,77x1,78

60 160.2140 O-ring ID 14,00x1,78 Nominal pressure range p N 100 bar 100

65 160.2156 O-ring ID 15,60x1,78 160 bar 160

350 bar

350

70 049.3176 Back-up ring RD 14,1x17x1,4

75 049.3196 Back-up ring RD 16,1x19x1,4 Sealing material NBR

FKM (Viton) D1

Technical explanation see data sheet 1.0-100 Design index (subject to change)

2.1-548

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.1-546E 2/2 www.wandfluh.com Illustrations are not binding Data subject to change 1/3 Edition: 19 24 2.1-548 E

CH-3714 Frutigen Edition 10 33

Page 843