Page 348 - Softbound_Edition_19_en

P. 348

Proportional spool valve

Proportional spool valve Proportional spool valve

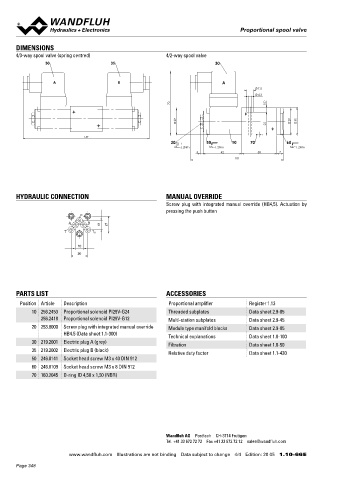

DIMENSIONS Proportional spool valve with integrated

4/3-way spool valve (spring centred) 4/2-way spool valve electronics and spool position control with LVDT NG4-Mini

30 35 30 Flange construction Wandfluh standard

◆ direct operated

◆ Q = 20 l/min

A B A Q max = 8 l/min

7.5 ◆ N max

4.2 ◆ p = 315 bar

max

70 5

DESCRIPTION APPLICATION

29 29 30

25 Direct operated proportional spool valve with 4 connections in Proportional spool valves are perfectly suitable for demanding

5-chamber system. With the integrated spool position sensor tasks due to the high resolution, large volume flow and low hystere-

149 (LVDT), the actual position of the spool is continuously recorded sis. They are used where good valve–to–valve reproducibility, easy

20 50 10 70 60 and made to follow the transmitted command value. By means of installation, comfortable operation and high precision are very im-

MD= 5.2Nm MD=1.2Nm MD=1.2Nm this internal position control, a minimum hysteresis and excellent portant. The integrated controller reliefs the machine control and

3 42 38 7

101 dynamic characteristics are assured. The Plug & Play valves are operates the axis (position, angle, pressure, etc.) in a closed cont-

factory set and adjusted and have therefore a high valve-to-valve rol loop. The applications are in the industry as well as in the mobile

reproducibility. Proportional to the electronically transmitted hydraulics for the smooth control of hydraulic actuators. Some

command value, the spool stroke, the spool opening and the valve examples: control of the rotor blades of wind generators, forestry

volume flow increase. The control takes place via an analogue and earth moving machines, machine tools and paper production

interface or a fieldbus interface (CANopen, J1939 or Profibus DP). machines, simple position controls, robotics and fan control.

HYDRAULIC CONNECTION MANUAL OVERRIDE The parameterisation takes place by means of the free of cost para - Miniature values are used where both, reduced dimensions and

Screw plug with integrated manual override (HB4,5). Actuation by meterisation and diagnostics software «PASO» or via fieldbus weight are important.

pressing the push button interface. The USB parameterisation interface is accessible

P

through a screw plug. As an option, these valves are available with

A B 11 21 integrated controller. As feedback value generators sensors with

T T 0 voltage or current output can be connected directly. The available

controller structures are optimised for applications with hydraulic

10 actuations.

20

SYMBOL

Symmetrical control Meter-in control

S4D41 V4D42

PARTS LIST ACCESSORIES A B A B

0

Position Article Description Proportional amplifier Register 1.13 a 0 b a b

a b a b

10 256.2453 Proportional solenoid PI29V-G24 Threaded subplates Data sheet 2.9-05

256.2418 Proportional solenoid PI29V-G12 Multi-station subplates Data sheet 2.9-45 P T P T

20 253.8000 Screw plug with integrated manual override Module type manifold blocks Data sheet 2.9-85

HB4.5 (Data sheet 1.1-300)

Technical explanations Data sheet 1.0-100

30 219.2001 Electric plug A (grey) Filtration Data sheet 1.0-50

35 219.2002 Electric plug B (black) ELECTRICAL SPECIFICATIONS ACTUATION

Relative duty factor Data sheet 1.1-430

50 246.0141 Socket head screw M3 x 40 DIN 912 Protection class IP67 with suitable mating connector and Actuation Proportional solenoid, wet pin push

60 246.0109 Socket head screw M3 x 8 DIN 912 closed housing cover type, pressure tight

70 160.2045 O-ring ID 4,50 x 1,50 (NBR) Ramps Adjustable Connection Via device receptacle

Parameterisation Via fieldbus or USB

Supply voltage 24 VDC

Note! Exact electrical specifications and detailed description

of «DSV» electronics can be found on data sheet

1.13-76.

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 20 05 1.10-66 E www.wandfluh.com Illustrations are not binding Data subject to change 1/6 Edition: 21 48 1.10-70 E

Page 348