Page 1128 - Softbound_Edition_19_en

P. 1128

Throttle valve

Throttle valves Throttle valve

Throttle non-return cartridge

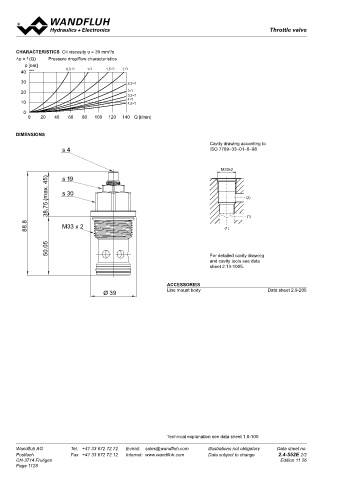

CHARACTERISTICS Oil viscosity υ = 30 mm /s Q = 25 l/min M18 x 1,5

2

∆p = f (Q) Pressure drop/flow characteristics ◆ Q max = 25 l/min ISO 7789

p [bar] ◆ N max

40 K4036 0,5 1 1,5 2 ◆ p = 350 bar

max

30 2,5

20 3

3,5

4 DESCRIPTION APPLICATION

10 4,5

Mecanically adjustable throttle valve in screw-in cartridge const- Throttle non-return valves are used where the volume flow in the

0 ruction for cavity according to ISO 7789. The one-piece throttle one direction via the spring loaded non-return valve has to be near-

0 20 40 60 80 100 120 140 Q [l/min]

1 2 non-return spool shifts into the completely open position with the ly free. In the opposite direction, the oil flows via the continuously

volume flow direction 2 to 1. The opening pressure of the valve is 1 adjustable, load depending throttle. The screw-in cartridge is

DIMENSIONS bar. With the volume flow direction from 1 to 2, the spool is pressed perfectly suitable for installation in control blocks and is installed in

against the adjustment spindle and reduces the volume flow to the sandwich plates (vertical stacked systems, corresponding data

Cavity drawing according to

s 4 ISO 7789–33–01–0–98 required extent via the throttle area, resp., throttle notch, milled sheets in this register). For machining the cartridge cavity in steel

laterally on the cone. When the adjustment spindle is screwed out, and aluminum blocks, cavity tools are available (hire or purchase).

the throttle closes practically leakage-free from 1 to 2, because the Please refer to the data sheets in register 2.13.

M33x2 hydraulic pressure and the spring press the throttle non-return

spool into the closed position.

s 19

(max. 45) s 30 (2) SYMBOL ACTUATION

38.75 (1) 2 Actuation Adjustment spindle M8 x 1

S = blockable key adjustment

Execution

D = blockable knob adjustment

88.8 M33 x 2 (1) Optionally:

K = lockable adjustment

1 G = star handle adjustment

50.05 Actuation angle → see Data sheet 2.0-50

a = 1800 ° (5 rotations)

For detailed cavity drawing

b

and cavity tools see data Actuation stroke S = 5 mm

b

sheet 2.13-1005.

TYPE CODE

ACCESSORIES DR PM18 - - #

Ø 39 Line mount body Data sheet 2.9-205 Throttle non-return valve

Type of adjustment Key S

Control knob D

Cover A

Screw-in cartridge M18 x 1,5

Nominal volume flow rate Q N 3,2 l/min 3,2

25 l/min 25

Sealing material NBR

FKM (Viton) D1

NBR 872 Z604

Design index (subject to change)

2.4-610

INSTALLATION NOTES STANDARDS

Mounting type Screw-in cartridge M18 x 1,5 Cartridge cavity ISO 7789

Mounting position Any, preferably horizontal Contamination ISO 4406

Tightening torque M = 40 Nm Screw-in cartridge efficiency

Technical explanation see data sheet 1.0-100 D

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.4-552E 2/2 www.wandfluh.com Illustrations are not binding Data subject to change 1/3 Edition: 19 11 2.4-610 E

CH-3714 Frutigen Edition 11 26

Page 1128