Page 1126 - Softbound_Edition_19_en

P. 1126

Throttle valve

Throttle valves Throttle valves

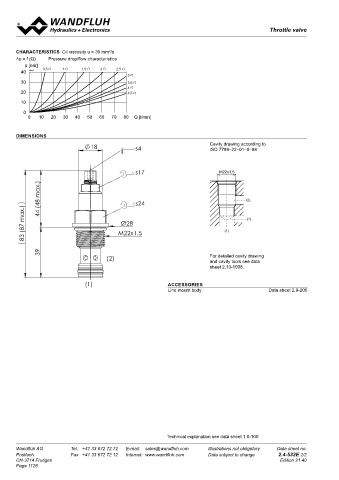

CHARACTERISTICS Oil viscosity υ = 30 mm /s Throttle valve

2

∆p = f (Q) Pressure drop/flow characteristics Screw-in cartridge M33x2

p [bar] • Q N max = 140 l/min ISO 7789

40 K4037 0,5 1 1,5 2 2,5 • Q = 140 l/min

3 • p max = 350 bar

30 3,5 max

4

20 4,5

DESCRIPTION FUNCTION APPLICATION

10 Manually adjustable, M33x2 screw-in cart- A fine tread on the adjustable throttle reveals Throttle valves can be used anywhere where

ridge throttle valve in accordance with cavity an annular gap. The adjusted throttle cross- volume flows can be infinitely controlled in both

0

0 10 20 30 40 50 60 70 80 Q [l/min] ISO 7789. The cartridge body made of steel is section produces a pressure drop which de- directions without taking pressure fluctuations

galvanized and therefore rust-protected. termines the volume flow. The volume flow is into account. Stepped tools are available for

zero when the throttle is screwed in (the metal making the receptacle bores in steel and alu-

sealing edge seals completely). The valve flow minium (hire or purchase). Please refer to the

DIMENSIONS is bidirectional. data sheets in register 2.13.

18 s4 Cavity drawing according to

ISO 7789–22–01–0–98

s17 M22x1,5 TYPE CODE

44 (48 max.) s24 (2) Throttle valve DN I PM33 - 140 #

83 (87 max.) M22x1.5 (1) (1) Screw-in cartridge M33x2 N 140 l/min

Type of adjustment

Ø28

Nominal volume flow rate Q

Design-Index (Subject to change)

39 (2) For detailed cavity drawing

and cavity tools see data

sheet 2.13-1008.

(1) ACCESSORIES

Line mount body Data sheet 2.9-205 GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

Description Throttle valve Fluid Mineral oil, other fluid on request

Construction Screw-in cartridge for cavity Contamination efficiency ISO 4406:1999,

acc. to ISO 7789 class 20/18/14…21/19/15

Mounting Screw-in thread M33x2 Required filtration grade (ß 10…25 ≥ 75)

Ambient temperature -20…+50 °C (refer to data sheet 1.0-50/2)

Mounting position any Viscosity range 12mm /s…320mm /s

2

2

Fastening torque M = 80 Nm Fluid temperature -20…+70 °C

D

Weight m = 0,37 kg Peak pressure p max = 350 bar

Volume flow direction 1 ↔ 2 Nominal volume flow rates Q = 140 l/min

N

Q at 10 bar valve pressure loss

N

Max. volume flow Q max = 140 l/min

Leakage volume flow Almost leak free with closed restrictor

SYMBOL

MECHANICAL ACTUATION

1 2 Screw adjustment with fork wrench and Allen key

Control storke S b = 4,5 mm

Control angle α = 1620° / 4,5 turns

b

s 4

Technical explanation see data sheet 1.0-100

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

s 19

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.4-532E 2/2 Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.4-552E 1/2

CH-3714 Frutigen Edition 21 40 (max. 45) CH-3714 Frutigen Edition 11 26

Page 1126 s 30

38.75

88.8 M33 x 2

50.05

Ø 39