Industrial

Designed for efficiency, productivity, precision, and longevity

Hydraulic systems for the production of the future

Applications in the machinery industry have always focused on precision, efficiency, and reliability. With the advent of Industry 4.0, the industrial production landscape is evolving, leading to new expectations for hydraulic systems. The requirements for valves and electronic components are becoming increasingly complex. These components must consistently provide precision, adaptability to specific machinery, future proof the systems, and provide responsive control behavior.

We meet these standards through the innovative design of our intelligent electronics and corresponding software that work in harmony with our valve products. This approach ensures the realization of precise and dynamic motion sequences in industrial production systems.

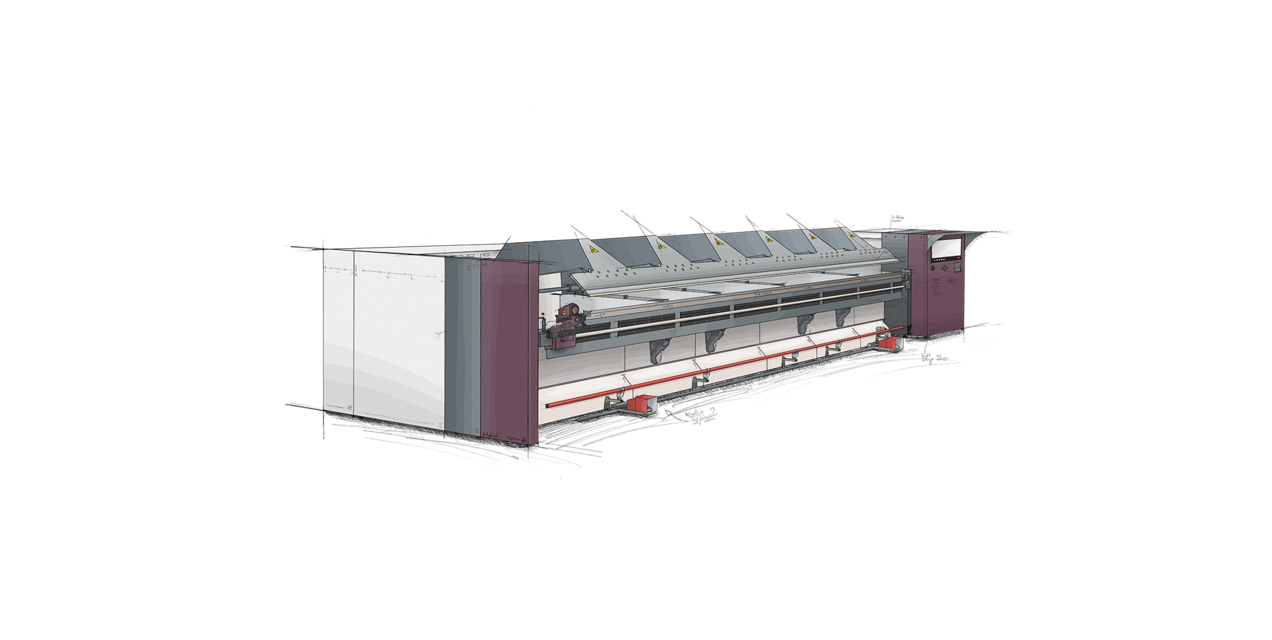

Application bending machine

In advanced bending machines, hydraulic actuators are managed by responsive proportional valves and intelligent electronics. This allows for quick adjustments to accommodate various materials and bending processes. While precise positioning of the actuators is crucial, compliance with strict safety requirements is mandated. Wandfluh can support safety systems by monitoring of the valve positions using integrated sensors.

Application clamping systems

A stable clamping force provided by workholding devices is essential for precise and safe machining. Ensuring high-pressure accuracy allows for uniform part clamping and helps prevent vibrations or displacement in jigs and fixtures. With Wandfluh integrated pressure protection, the clamping force remains consistent even during a power failure, reducing the risk of accidents.

Application press construction

High working pressures and large oil volume flows are key requirements in press construction. The machines are cost-intensive and differ primarily in terms of their performance and efficiency. Decisive factors here are fast press cycles, high process reliability and energy-efficient hydraulic components. These requirements also apply to die casting technology, where comparable valve technology is used.

What sets us apart

- Integrated hydraulic systems utilizing in-house electronics

- State-of-the-art valve technology with spool LVDT feedback

- High power density (up to 350 bar / 120 l/min)

- Compact designs with a small footprint (NG3-Mini, NG4-Mini)

- High response, precision, and repeatability

- Linear characteristics with low hysteresis

- Precise flow and pressure control for fine adjustments

- Low maintenance requirements

- Custom adaptations available for individual customers

- Worldwide customer service

Electronic Controls

A comprehensive range of amplifiers and controllers is available for valve management. These digital modules are individually configurable and can be precisely set using the PASO configuration software, which employs a structured block diagram approach. This method enhances clarity and intuitiveness in understanding control paths, as well as simplifies setup and installation.

Additionally, the PASO program provides real-time monitoring of controller health and features integrated data logging for current parameters, allowing for thorough analysis of operational data. Alongside electronic modules designed for discrete installation into control cabinets, Wandfluh also offers valves with on-board electronics (OBE) that come factory-calibrated and nulled to ensure simple and easy installation.

To the products

Various valves, control electronics and much more - here you will find an overview of our products with applications for industrial applications.

Features of our products

Here you will find more information about the specific properties of our products.

Individual solutions

Our valves have a modular design and are very flexible in their composition. In this way, various standard functional elements can be combined with each other and individual solutions are easy to implement.