Explosion protection

Hazardous locations require explosion-proof products

In contact with oxygen, gases, vapors or dust can explode. To ensure safety at all times, explosion protection is a top priority in our products.

Explosion Proof (Ex)

The Wandfluh Flameproof solenoid coil housing (Ex) is designed according to EN IEC 60079-1 and is essential for critical applications where electro-hydraulic system valves could ignite an explosive atmosphere. To ensure safety, the solenoid coil housing must contain and withstand any pressure created from potential internal thermal events caused by coil issues, preventing excessive heat and energy from escaping into the surrounding environment.

The housing design incorporates long and narrow internal vent channels that help dissipate any heat generated internally. Additionally, only the internal areas necessary for the EX secure manufacturing process are hermetically sealed to further maintain safety. Technically necessary gaps are designed to be so long and narrow that any hot gases escaping outside the housing lose their flammability. Only gaps required for the manufacturing process are hermetically sealed.

MKY45/18x60

The solenoid coil in accordance with Directive 2014/34/EU (ATEX) is suitable for use in potentially explosive atmospheres. The flameproof enclosure in accordance with EN IEC 60079-1/31 prevents an internal explosion from reaching the outside. It is designed in such a way that no ignitable surface temperatures occur.

Features

- IP65/66/67 protection rating

- AISI 316L surface finish

- Optional integrated amplification electronics

Intrinsic Safety (Ex ia)

Intrinsic safety (Ex ia) in accordance with EN IEC 60079-11 ensures that the equipment contains only electronic apparatus that meet the requirements for low current intrinsically safe operation.

These products are designed in such a way that they do not generate internal sparks or thermal effects even under the strict normal operation and certain fault condition test conditions specified in the standard, that could ignite an explosive atmosphere of subgroups IIA, IIB, IIC or dust-air mixtures of group III.

Coil Option: M_Z45

The M_Z45 solenoid coil option is designed for use with spool valves in potentially explosive atmospheres that must meet Intrinsically safe operating standards. Wandfluh recommends that in order to fully comply, one of the separate Intrinsic Security Power Supplies recommended in the M_Z45 data sheet is chosen to match the selected coil resistance and MUST be used at all times.

Features

- Protection class IP65/66/67

- Surface finish AISI 316L

- Optionally available with integrated amplifier electronics

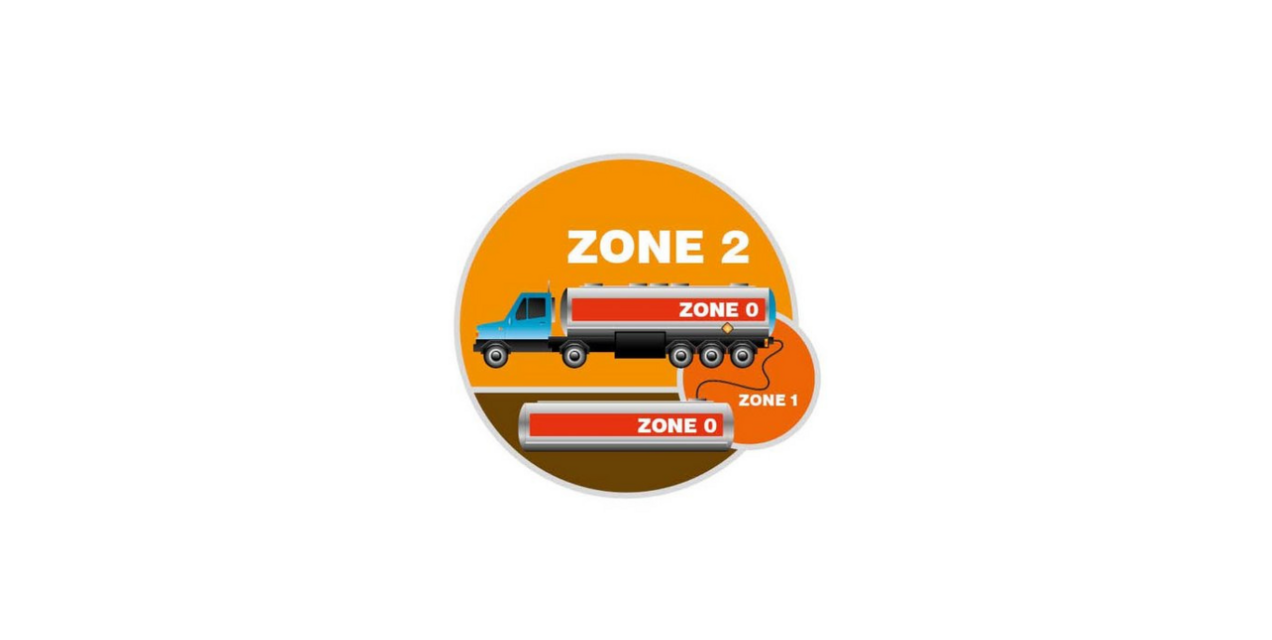

Explosion protection zones

Potentially explosive areas are assessed according to their hazard potential and divided into corresponding zones. We distinguish between the following six explosion protection zones:

Areas at risk of gas explosions

Zone 0: This zone represents the highest level of risk, where an explosive atmosphere is continuously or frequently present. It's an area where ignitable concentrations of flammable gases or vapors are present continuously, or for long periods, or frequently.

Zone 1: This zone is characterized by a high probability of an explosive atmosphere occurring under normal operating conditions. It's an area where ignitable concentrations of flammable gases or vapors are likely to occur occasionally.

Zone 2: This zone represents a lower risk, where an explosive atmosphere is unlikely to occur under normal operating conditions. If an explosive atmosphere does occur, it is likely to exist only for a short time.

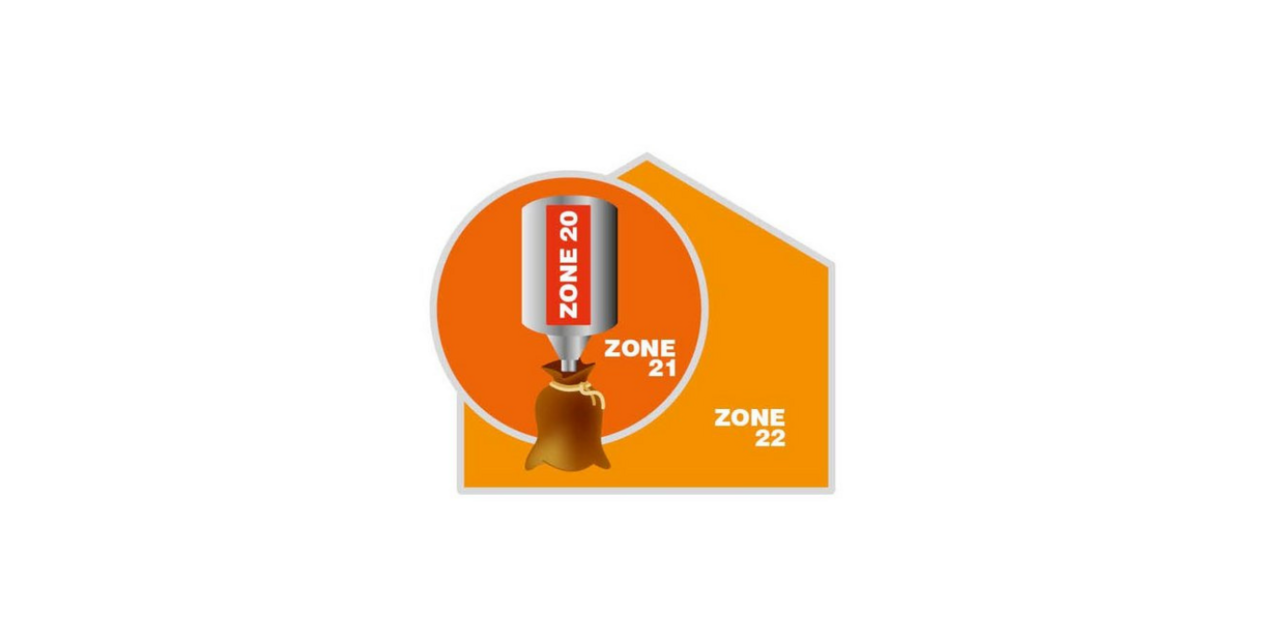

Areas with flammable dusts

Zone 20: This zone is characterized by the continuous or frequent presence of a cloud of combustible dust in the air. It's considered the most hazardous dust zone, requiring the highest level of protection for equipment.

Zone 21: In this zone, a cloud of combustible dust is likely to occur during normal operation, although not continuously. This zone requires a medium level of protection for equipment.

Zone 22: This zone is classified as a location where a dust cloud is not likely to occur under normal operating conditions, and if it does, it will only be present for a short period. This zone requires the least stringent level of protection for equipment.

Types of protection

Our innovation and proven Ex Coil design techniques ensure that all operational characteristics are in accordance with the Classes, Divisions, and Groups or Zones of an assumed explosive mixture.

Each EX or EX ia coil has multiple options available allowing the final selection to meet the criteria required by the system that will operate in the hazardous area.

Certificates

Our solenoid coils are certified for use in zones with potentially explosive gas, vapor, air and dust mixtures in zones 1/21 and 2/22.

- Ex db IIC T6, T4 Gb

- Ex tb IIIC T80°C, T130°C Db

- Ex db I M

- Ex ia I Ma

- Ex ia II C T5/T6

- (Ex)II 2 G Ex db IIC T6, T4

- (Ex)II 2 D Ex tb IIIC T80°C, T130°C

- (Ex) I M2 Ex db I Mb

- (Ex) I M1 Ex ia I Ma

- (Ex) II 1G Ex ia IIC Ga T6, T5

Application examples

Surface and Underground Mining

Hydraulic systems play a crucial role in various tasks within the mining industry. These applications often occur in potentially explosive environments, such as those containing dust, flammable liquids, or gases. To prevent explosions, explosion-proof technology is essential. This is especially critical in underground mining, where an explosion could lead to severe injuries, significant material damage, and even the collapse of the mine.

Tankers and LNG ships

Explosion-proof equipment is vital on tankers and LNG ships due to the constant presence of highly flammable cargo and vapors. It is deployed in "hazardous areas" such as cargo tanks, pump rooms, manifold areas, and ventilation outlets. This equipment, including electro-hydraulics and control systems, is engineered to prevent and contain any internal sparks or explosions, preventing them from igniting the surrounding volatile atmosphere, thereby ensuring the safety of crew, cargo, and the vessel. International maritime regulations mandate its use

Hydraulic valves and systems in port facilities control critical machinery like cranes, reach stackers, and container handlers. They precisely direct fluid flow to power lifting, steering, and braking systems, enabling efficient and safe cargo operations.

Hydraulic flow and pressure control valves are extensively used in offshore facilities for critical functions like controlling blowout preventers (BoP’s), operating subsea equipment (RoV’s), managing crane and winch torque systems, and precise speed regulation in drilling and production processes.

Hydraulic valves in chemical plants control fluid flow, pressure, and temperature within process lines, reactors, and various machinery. They're essential for precise chemical dosing, mixing, separation, and shit-off safety systems.

Durable and corrosion-resistant valves

In various application markets, particularly those requiring strong corrosion protection, advanced technology is essential. Wandfluh valves are constructed from rust- and acid-resistant steel, providing high resistance to challenging conditions such as saltwater, moisture, and abrasive substances.

These valves are utilized in demanding environments and to address the diverse solution requirements, we offer a range of flow and pressure valves available with numerous options. This ensures that we can deliver the right products that promise reliable performance and a long service life, even under extreme operating conditions.