Corrosion protection

Reliable, proven surface protection options.

Constant exposure to saltwater and high-salinity air environments necessitates components with superior corrosion protection. With material upgrades in our Class K8, K9, and K10 providing protection for over 1,000 hours against red rust, we can ensure the right level of defense to maximize product lifetime.

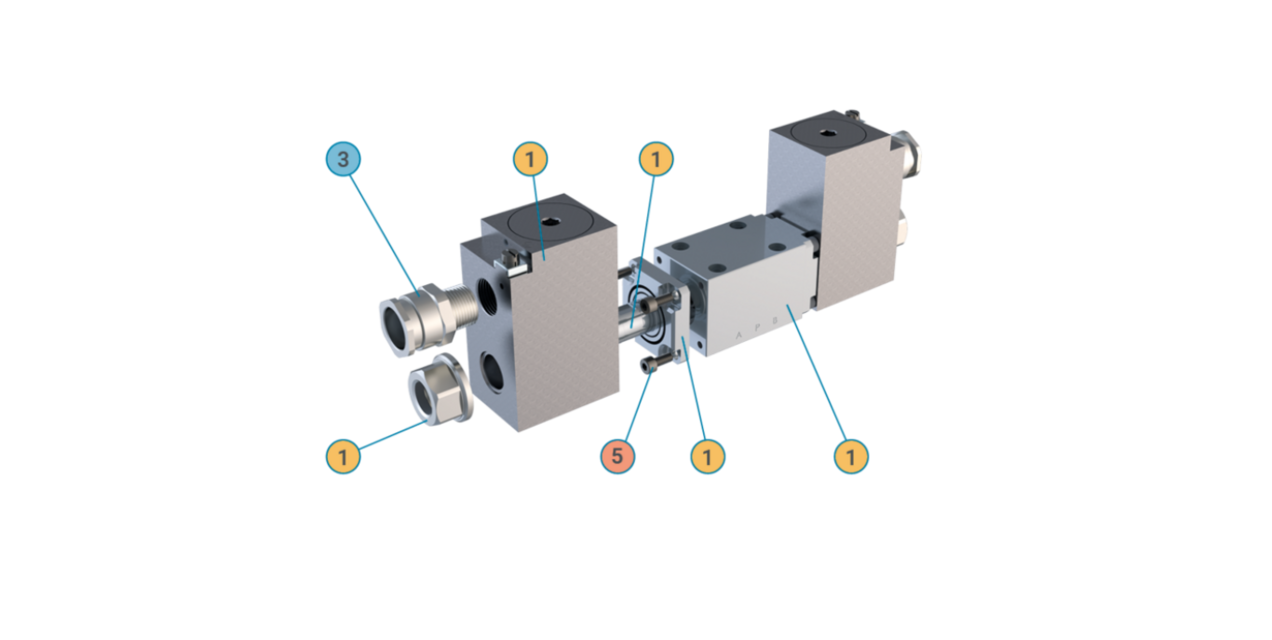

Valve actuation for corrosive and explosive atmospheres

For use in potentially explosive and corrosive environments, this product complies with Directive 2014/34/EU (ATEX). The flameproof enclosure, in accordance with IEC 60079-1/31, not only prevents internal explosions from escaping to the outside but is also constructed from AISI 316L stainless steel.

The certified design ensures that surface temperatures remain below ignition points and protects the coil surface from erosion caused by the external environment.

Features solenoid coil MKY45/18x60

- For potentially explosive and corrosive atmospheres

- Protection class IP65/66/67

- Surface finish AISI 316L

- Optionally with integrated proportional amplifier electronics

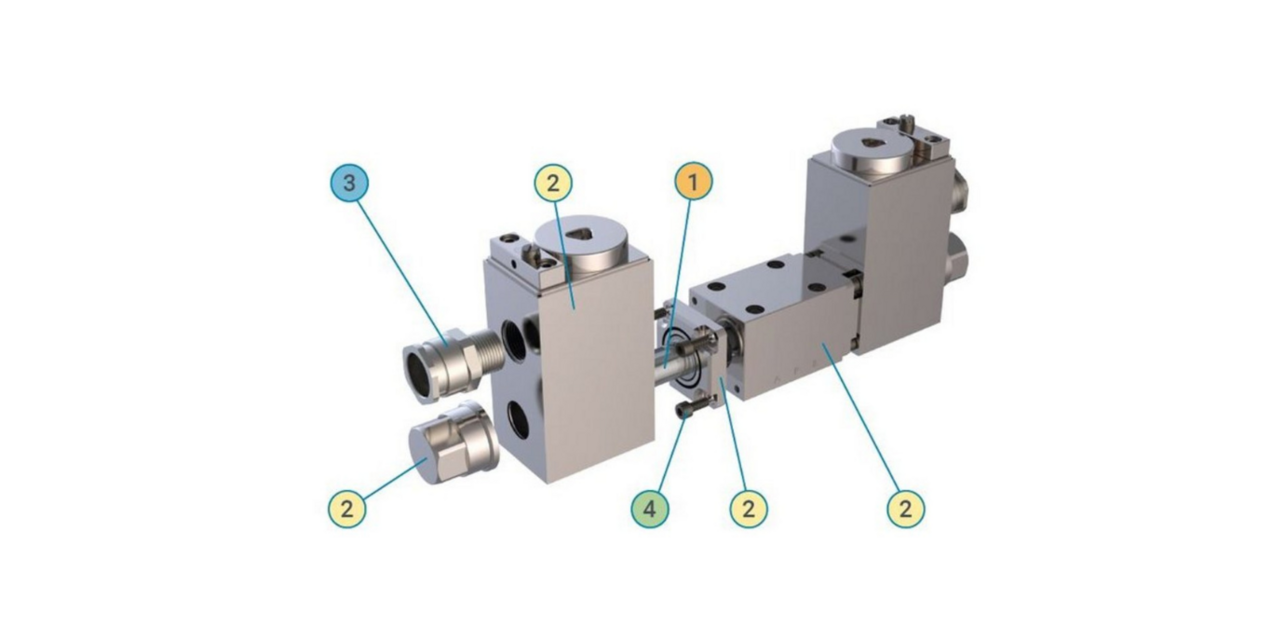

Corrosion protection class K8 (500-1,000 h salt spray test)

Wandfluh standard valves and components are designed to meet the K8 protection level, which includes a salt spray test according to EN ISO 9227. They provide 500 to 1,000 hours of protection to red rust, and are made from rust- and acid-resistant steel, typically plated with zinc-nickel to ensure excellent resistance and provide off-the-shelf high resistance to surface damage.

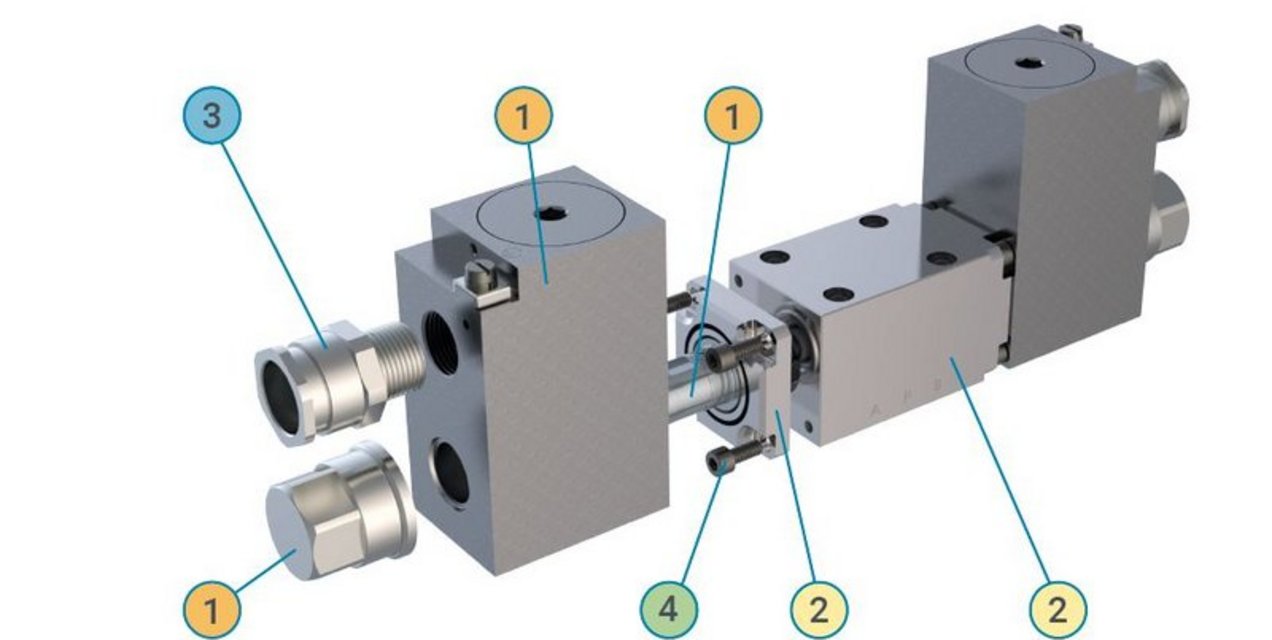

Corrosion protection class K9 (1,000 h salt spray test)

All external parts are made of AISI 316L stainless steel and are therefore resistant to corrosion, acids and chlorine. With the exception of the solenoid coil housing, which is coated with zinc-nickel. The rust resistance is at least 1,000 h salt spray test according to EN ISO 9227.

K9 is particularly suitable for extreme conditions, offshore and marine applications.

Corrosion protection class K10 (>1,000 h salt spray test)

All external parts, i.e. valve body and solenoid coil, are made of AISI 316L stainless steel. The corrosion resistance is at least 2,000 h salt spray test according to EN ISO 9227.

The highest level of corrosion protection is only applied to valves fitted with the explosion-proof solenoid coil MKY.

Salt spray test

In the salt spray test, the valve is exposed to a salt mist in accordance with ISO 9227, using a five percent NaCl solution to test the corrosion resistance. During the test, it is observed how long it takes for the first signs of red rust to appear. This test simulates extremely corrosive conditions and is an important indicator of the longevity and robustness of the valves in demanding environments.

Certificates

The coils are approved for use in areas with potentially explosive gas, vapor, mist, air and dust mixtures for zones 1/21 and 2/22.

- Ex db IIC T6, T4 Gb

- Ex tb IIIC T80°C, T130°C Db

- Ex db I Mb

- (Ex) II 2 G Ex db IIC T6, T4

- (Ex) II 2 D Ex tb IIIC T80°C, T130°C

- (Ex) I M2 Ex db I Mb

Robust protection for extreme operating conditions

In specialized markets that require stronger protection against corrosive atmospheres, high salinity environments, or aggressive liquids, advanced material offerings are crucial.

Wandfluh standard valves all meet the K8 standard and are made from rust- and acid-resistant steel, which is typically zinc-nickel plated to provide off-the-shelf high resistance to surface damage.

If additional protection from environmental erosion is needed, Wandfluh offers upgraded materials, including AISI 316L stainless steel, which provides >1000 hours of protection to red rust.