Page 358 - Softbound_Edition_19_en

P. 358

Proportional spool valve

Proportional spool valve Proportional spool valve

PERFORMANCE SPECIFICATIONS INSTALLATION NOTES MANUAL OVERRIDE

Oil viscosity u = 30 mm /s Mounting type Flange mounting ◆ Integrated (–) Actuation pin integrated in the armature tube.

2

Actuation by pressing the pin

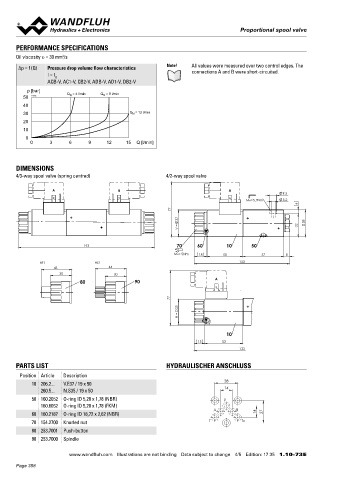

Δp = f (Q) Pressure drop volume flow characteristics Note! All values were measured over two control edges. The 3 fixing holes for ◆ Push-button (HF1) Integrated in the knurled nut. Actuation by

I = I G connections A and B were short-circuited. socket head screws M5 x 40 pressing the push-button

ACB-V, AC1-V, CB2-V, ADB-V, AD1-V, DB2-V Mounting position Any, preferably horizontal ◆ Spindle (HS1) Integrated in the knurled nut. Actuation by turning

Tightening torque M = 5,2 Nm (screw quality 8.8, zinc

p [bar] Q = 8 l/min D the spindle (continuously variable valve actuation)

50 K4045 Q N = 4 l/min N coated) Fixing screws Attention! The actuation of the manual override is possible up to a

M = 5 Nm knurled nut

40 D tank pressure of:

30 Q N = 12 l/min Note! The length of the fixing screw depends on the base 160 bar Integrated (–)

material of the connection element. 160 bar Push-button (HF1)

20 160 bar Spindle (HS1)

10

0

0 3 6 9 12 15 Q [l/min] STANDARDS ACCESSORIES

Mounting interface Wandfluh standard Mating connector grey (A) Article no. 219.2001

Solenoids DIN VDE 0580 Mating connector black (B) Article no. 219.2002

DIMENSIONS Connection execution D EN 175301 – 803 Threaded subplates Data sheet 2.9-10

4/3-way spool valve (spring centred) 4/2-way spool valve Protection class EN 60 529 Multi-station subplates Data sheet 2.9-50

Contamination efficiency ISO 4406 Horizontal mounting blocks Data sheet 2.9-90

A B A

9.5 Explications techniques Data sheet 1.0-100

MD=5.2Nm 5.2

6 Hydraulic fluids Data sheet 1.0-50

77 Filtration Data sheet 1.0-50

37 38 Relative duty factor Data sheet 1.1-430

V = 32 Proportional amplifier Register 1.13

193 70 60 10 50

MD= 5Nm 18 50 57 8 SURFACE TREATMENT SEALING MATERIAL

HF1 HS1 133 ◆ The valve body is painted with a two component paint NBR or FKM (Viton) as standard, choice in the type code

43 44 ◆ The armature tube and the plug screw are zinc coated

30 30 The slip-on coil is zinc-nickel coated

80 90 A ◆

77

35

N =

10

15 53

133

PARTS LIST HYDRAULISCHER ANSCHLUSS

Position Article Description

28

10 206.2... V.E37 / 19 x 50

260.5... N.S35 / 19 x 50 14

50 160.2052 O-ring ID 5,28 x 1,78 (NBR) P

160.6052 O-ring ID 5,28 x 1,78 (FKM)

A B

60 160.2187 O-ring ID 18,72 x 2,62 (NBR) 14 27

70 154.2700 Knurled nut T T0

80 253.7001 Push-button

90 253.7000 Spindle Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

www.wandfluh.com Illustrations are not binding Data subject to change 4/5 Edition: 17 35 1.10-73 E www.wandfluh.com Illustrations are not binding Data subject to change 5/5 Edition: 17 35 1.10-73 E

Page 358