Page 322 - Softbound_Edition_19_en

P. 322

Spool valve

Spool valve Spool valve

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS MANUAL OVERRIDE ACCESSORIES

Designation 4/2-spool valve Working pressure p = 315 bar Integrated in the cover. Actuation by pressing the pin. Fixing screws Data sheet 1.0-60

max

Construction Direct operated Tank pressure p = 160 bar Threaded subplates Data sheet 2.9-40

T max

Mounting Flange construction System pressure 25…315 bar Multi-station subplates Data sheet 2.9-70

Nominal size NG10 according to ISO 4401-05 Reversal pressure Maximum 90% of the system pressure Horizontal mounting blocks Data sheet 2.9-110

Actuation Integral pressure reversal Maximum volume flow Q = 60 l/min, see characteristics

max Technical explanations Data sheet 1.0-100

Ambient temperature -25…+70 °C Minimum volume flow Q = 4 l/min

min Filtration Data sheet 1.0-50

Weight 4,8 kg Fluid Mineral oil, other fluid on request

MTTFd 150 years Viscosity range 12 mm /s…320 mm /s

2

2

Temperature range -25…+70 °C (NBR)

fluid -20…+70 °C (FKM)

Contamination Class 20 / 18 / 14

efficiency

Filtration Required filtration grade ß 10…16 ≥ 75, SEALING MATERIAL COMMISSIONING

see data sheet 1.0-50 NBR or FKM (Viton) as standard, choice in the type code Attention! The reversal pressure adjusted on the pressure reliefs

must not exceed a maximum of 90% of the system

pressure.

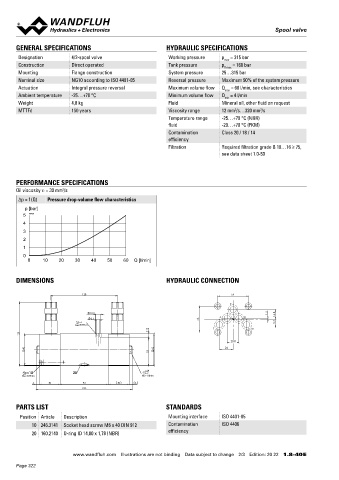

PERFORMANCE SPECIFICATIONS

2

Oil viscosity u = 30 mm /s

Δp = f (Q) Pressure drop-volume flow characteristics

p [bar] INSTALLATION NOTES SURFACE TREATMENT

5 K0435 The valve body is coated with a two component paint

Mounting type Flange mounting ◆

4 The covers and the screws are zinc coated

4 fixing holes for ◆

3 socket head screws M6 x 65

2 Mounting position Any, preferably horizontal

1 Tightening torque Fixing screws M = 8,9 Nm (quality 8.8,

D

0 zinc coated)

0 10 20 30 40 50 60 Q [l/min]

Note! The length of the fixing screw depends on the base

material of the connection element.

DIMENSIONS HYDRAULIC CONNECTION

128 54

P

10.5 1.5

16.8

6.5 46 A B

MD=8.9Nm 9.7

T To

7

123

20.8

60 62 24

55

10 20 s14

MD= 8.9Nm MD= 10Nm

6 40 93 40 6

185

PARTS LIST STANDARDS

Position Article Description Mounting interface ISO 4401-05

10 246.3141 Socket head screw M6 x 40 DIN 912 Contamination ISO 4406

20 160.2140 O-ring ID 14,00 x 1,78 (NBR) efficiency Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

www.wandfluh.com Illustrations are not binding Data subject to change 2/3 Edition: 20 22 1.8-40 E www.wandfluh.com Illustrations are not binding Data subject to change 3/3 Edition: 20 22 1.8-40 E

Page 322