Page 314 - Softbound_Edition_19_en

P. 314

Spool valve

Spool valve Spool valve

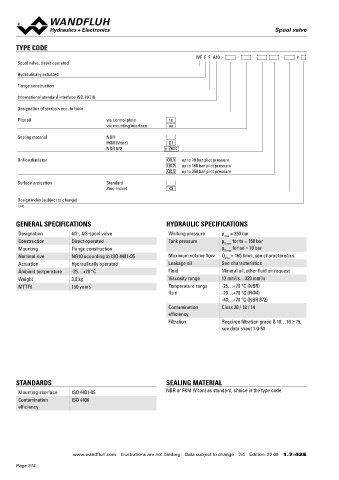

TYPE CODE ACTUATION INSTALLATION NOTES

WF F F A10 - - - - # Actuation Hydraulically operated Mounting type Flange mounting

Spool valve, direct operated Pilot pressure Recommended p = 20 bar 4 fixing holes for

v

∆p (x-y) < 3 bar for a stable position socket head screws M6 x 40

Hydraulically actuated

∆p (x-y) > 12 bar for secure switching Mounting position Any, preferably horizontal

Flange construction Tightening torque M = 10.5 Nm ± 10 %, quality 8.8

D

International standard interface ISO, NG10 Note! The length of the fixing screw depends on the base

material of the connection element.

Designation of symbols acc. to table

Pilot oil via control plate te

via mounting interface ae

Sealing material NBR PERFORMANCE SPECIFICATIONS

FKM (Viton) D1 Oil viscosity u = 30 mm /s

2

NBR 872 y-Z604

p = f (Q) Performance limits Q = f (Q) Leakage volume flow characteristics

Orifice diameter Q0,9 up to 70 bar pilot pressure L per control edge

Q0,7 up to 160 bar pilot pressure

Q0,6 up to 350 bar pilot pressure p [bar] Q [cm /min]

3

350 K4263 200 K4264

Surface protection Standard 300

Zinc-nickel K8 250 150

200

Design index (subject to change) 150 100

1.7-42 100 50

50

0 Q [l/min] 0 p [bar]

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS 0 20 40 60 80 100 120 140 160 0 50 100 150 200 250 300 350

Designation 4/2-, 4/3-spool valve Working pressure p = 350 bar

max

Construction Direct operated Tank pressure p T max for te = 160 bar

Mounting Flange construction p T max for ae = 70 bar Δp = f (Q) Pressure drop-volume flow characteristics Volume flow direction

Nominal size NG10 according to ISO 4401-05 Maximum volume flow Q = 160 l/min, see characteristics ∆p [bar] Symbol P - A P - B P - T A - T B - T

max

Actuation Hydraulically operated Leakage oil See characteristics 20 K4265 1 BA1 / BA2 / BA3 3 3 - 2 1

Ambient temperature -25…+70 °C Fluid Mineral oil, other fluid on request 15 2 BCA 3 3 - 2 1

2

2

Weight 3,0 kg Viscosity range 12 mm /s…320 mm /s 3 BDA 3 3 - 2 1

MTTFd 150 years Temperature range -25…+70 °C (NBR) 10

fluid -20…+70 °C (FKM) 5

-40…+70 °C (NBR 872) 0

Contamination Class 20 / 18 / 14 0 20 40 60 80 100 120 140 160 Q [l/min]

efficiency

Filtration Required filtration grade ß 10…16 ≥ 75,

see data sheet 1.0-50

ACCESSORIES SURFACE TREATMENT

Fixing screws Data sheet 1.0-60 Standard:

Threaded subplates Data sheet 2.9-40 -The valve body is painted with a two component paint

-The screw plug and the control plate are zinc-nickel coated

Multi-station subplates Data sheet 2.9-70

Horizontal mounting blocks Data sheet 2.9-110 Optionally (K8):

STANDARDS SEALING MATERIAL Technical explanations Data sheet 1.0-100 -All external parts are zinc-nickel coated

Mounting interface ISO 4401-05 NBR or FKM (Viton) as standard, choice in the type code Filtration Data sheet 1.0-50 ISO 9227 (800 h) salt spray test

Contamination ISO 4406

efficiency

www.wandfluh.com Illustrations are not binding Data subject to change 2/4 Edition: 22 09 1.7-42 E www.wandfluh.com Illustrations are not binding Data subject to change 3/4 Edition: 22 09 1.7-42 E

Page 314