Page 1195 - Softbound_Edition_19_en

P. 1195

Pressure compensating valves Pressure compensating valves

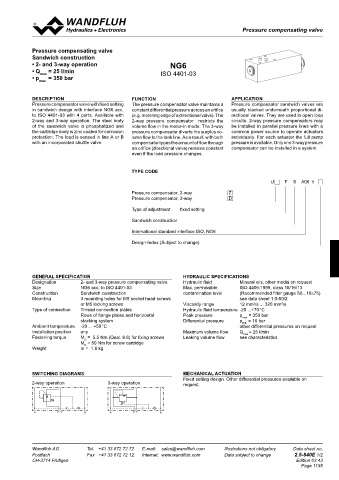

Pressure compensating valve

2

CHARACTERISTICS Oil viscosity υ = 30 mm /s Pressure compensating valve

∆p = f (Q) Pressure drop-volume flow curve Q = f (p) Leakage volume flow cruve Sandwich construction

L

2-way operation • 2- and 3-way operation NG6

p [bar] Q [cm /min] • Q max = 25 l/min ISO 4401-03

3

25 K0348 200 K0350 • p = 350 bar

max

20 150

15

100 DESCRIPTION FUNCTION aPPlICaTION

10 Pressure compensator valve with fixed setting The pressure compensator valve maintains a Pressure compensator sandwich valves are

5 50 in sandwich design with interface NG6 acc. constant differential pressure across an orifice usually stacked underneath proportional di-

to ISO 4401-03 with 4 ports. Available with (e.g. metering edge of a directional valve). The rectional valves. They are used in open loop

0 0 2-way and 3-way operation. The steel body 2-way pressure compensator restricts the circuits. 2-way pressure compensators may

0 2 4 6 8 10 Q [l/min] 0 50 100 150 200 250 300 350 p [bar] of the sandwich valve is phosphatized and volume flow in the meter-in mode. The 3-way be installed in parallel pressure lines with a

the cartridge body is zinc coated for corrosion pressure compensator diverts the surplus vo- common power source to operate actuators

protection. The load is sensed in line A or B lume flow to the tank line. As a result, with both individually. For each actuator the full pump

with an incorporated shuttle valve. compensator types the amount of flow through pressure is available. Only one 3-way pressure

DIMENSIONS an orifice (directional valve) remains constant compensator can be installed in a system.

SCREW-IN CARTRIDGES INSTALLED even if the load pressure changes.

20 Ø 5.5 The following screw-in cartridges are used in the sandwich body:

UZFSA04 Type Designation Data sheet no. TYPE CODE

2-way operation

2.5-630

UZFPM22

40 U F S A06 #

24 16 Pressure compensator, 2-way Z

Pressure compensator, 3-way D

10 Type of adjustment fixed setting

4.2 110 14.2

27 Sandwich construction

International standard interface ISO, NG6

P

Design-Index (Subject to change)

40 A B

14

T T0

24

20

Ø 5.5

14

28 GENERal SPECIFICaTION HYDRaUlIC SPECIFICaTIONS

UDFSA06

UZFSA06

Designation 2- and 3-way pressure compensating valve Hydraulic fluid Mineral oils, other media on request

Size NG6 acc. to ISO 4401-03 Max. permissible ISO 4406:1999, class 18/16/13

Construction Sandwich construction contamination level (Recommended filter gauge ß6...10≥75)

40

PARTS LIST ACCESSORIES Mounting 3 mounting holes for M5 socket head screws see data sheet 1.0-50/2

16

24

2

2

Thread connection plates and rows of flange plates register 2.9 or M5 locking screws Viscosity range 12 mm /s ... 320 mm /s

Position Article B Description A P T B Type of connection Thread connection plates Hydraulic fluid temperature -20 ...+70 °C

P T

A

10 Rows of flange plates and horizontal Peak pressure p = 350 bar

120

10 160.2052 O-Ring ID 5,28 x 1,78 4.2 32 stacking system 14.2 Differential pressure p max = 10 bar

Diff.

20 238.1405 Locking screw DIN 908 G1/8" Ambient temperature -20 ... +50 °C other differential pressures on request

19

21.5

Installation position any Maximum volume flow Q max = 25 l/min

Fastening torque M = 5,5 Nm (Qual. 8.8) for fixing screws Leaking volume flow see characteristics

D

M = 50 Nm for screw cartridge

T

D

Weight m = 1,8 kg

Technical explanation see data sheet 1.0-100 45 31 21 A B 32.5

16

P

SWITCHING DIaGRaMS MECHaNICal aCTUaTION

17.8 Fixed setting design. Other differential pressures available on

2-way operation 3-way operation request.

A P T B A P T B

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.5-820E 2/2 Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.5-840E 1/2

CH-3714 Frutigen Edition 21 33 CH-3714 Frutigen Edition 03 43

Page 1195