Page 1199 - Softbound_Edition_19_en

P. 1199

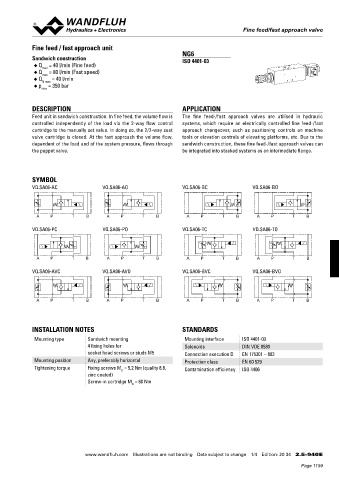

Fine feed / fast approach unit

Fine feed / fast approach valves Fine feed/fast approach valve

Fine feed / fast approach unit

CHArACTerISTICS Oil viscosity υ = 30 mm /s NG6

2

Q = f (p) Volume flow pressure characteristics (Fine feed) ∆p = f (Q) Pressure drops volume flow characteristic Sandwich construction

(Fast approach) ISO 4401-03

Q [l/min] ◆ Q = 40 l/min (Fine feed)

max

25 K0962 p [bar] ◆ Q = 80 l/min (Fast speed)

40 K0960 max

20 Q = 20 l/min ◆ Q N max = 40 l/min

N

15 Q = 16 l/min 30 ◆ p = 350 bar

max

N

10 20

5 Q N = 6,3 l/min 10

Q N = 2,5 l/min DESCRIPTION APPLICATION

0

0 50 100 150 200 250 300 350 p [bar] 0 Feed unit in sandwich construction. In fine feed, the volume flow is The fine feed-/fast approach valves are utilised in hydraulic

0 5 10 15 20 25 30 Q [l/min] controlled independently of the load via the 2-way flow control systems, which require an electrically controlled fine feed-/fast

∆p = f (Q) Pressure drop volume flow characteristic SCrew-IN CArTrIdGeS INSTALLed cartridge to the manually set value. In doing so, the 2/2-way seat approach changeover, such as positioning controls on machine

over non-return valve function of poppet valve The following screw-in cartridges are used in the sandwich body: valve cartridge is closed. At the fast approach the volume flow, tools or elevation controls of elevating platforms, etc. Due to the

p [bar]

40 K0961 Type Designation Data sheet no. dependent of the load and of the system pressure, flows through sandwich construction, these fine feed-/fast approach valves can

QZ.PM22 Flow control valve 2.5-535 the poppet valve. be integrated into stacked systems as an intermediate flange.

30

SVSPM22 Solenoid poppet valve 1.11-2082

20

10

SYMBOL

0 PArTS LIST VQ.SA06-AC VQ.SA06-AO VQ.SA06-BC VQ.SA06-BO

0 5 10 15 20 25 30 Q [l/min]

Position Article Description

ACCeSSOrIeS 10 160.2060 O-ring ID 6,07 x 1,78 (NBR)

Threaded connection plates and multi-flange subplates Register 2.9

Mating connector EN 175301-803 article no. 219.2002 A P T B A P T B A P T B A P T B

Technical explanation see data sheet 1.0-100

VQ.SA06-PC VQ.SA06-PO VQ.SA06-TC VQ.SA06-TO

TyPeS / dIMeNSIONS

VQ.SA04-PC VQ.SA04-PO

Control P, T, A, BV

VQ.SA04-PC VQ.SA04-PO A P T B A P T B A P T B A P T B

38.5

A P T B VQ.SA06-AVC VQ.SA06-AVO VQ.SA06-BVC VQ.SA06-BVO

VQ.SA04-TC VQ.SA04-TO

38.5 10

A P T B P

VQ.SA04-TC VQ.SA04-TO A B

40 10 T To

A PT B A PT B A P T B A P T B A P T B A P T B

VQ.SA04-AC VQ.SA04-AO A P B 76

40 T To

A PT B A PT B A

VQ.SA04-AC VQ.SA04-AO 53 65 65 58 76

A P T B A P T B 241 A INSTALLATION NOTES STANDARDS

VQ.SA04-BVC VQ.SA04-BVO 53 65 65 58 Mounting type Sandwich mounting Mounting interface ISO 4401-03

A P T B A P T B 241 4 fixing holes for Solenoids DIN VDE 0580

VQ.SA04-BVC VQ.SA04-BVO socket head screws or studs M5 Connection execution D EN 175301 – 803

Mounting position Any, preferably horizontal Protection class EN 60 529

A P T B A P T B Control AV, B Tightening torque Fixing screws M = 5,2 Nm (quality 8.8,

A P B zinc coated) D Contamination efficiency ISO 4406

T To

A P T VQ.SA04-AVC A P T VQ.SA04-AVO Screw-in cartridge M = 60 Nm

B

B

D

A P B

T To

VQ.SA04-AVC VQ.SA04-AVO B

A PT B A PT B

VQ.SA04-BC VQ.SA04-BO B

A PT B A PT B

VQ.SA04-BC VQ.SA04-BO

Dimensions of the other setting versions see data sheet 2.5-535

A P T B A P T B

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

A Postfach B A Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.5-920E 2/2 www.wandfluh.com Illustrations are not binding Data subject to change 1/4 Edition: 20 34 2.5-940 E

B

P

T

P

T

CH-3714 Frutigen Edition 12 33

Page 1199