Page 1192 - Softbound_Edition_19_en

P. 1192

48

10,5

6,5

Ø

Ø

54

53

7 )

(

105

6,5

Ø

(120)

35 60 35 10 * 30 46 9,7 16,8 1,5 46 20,8 50 * 30 60 60

60 170

Flow control valve

Flow control valves Pressure compensating valves

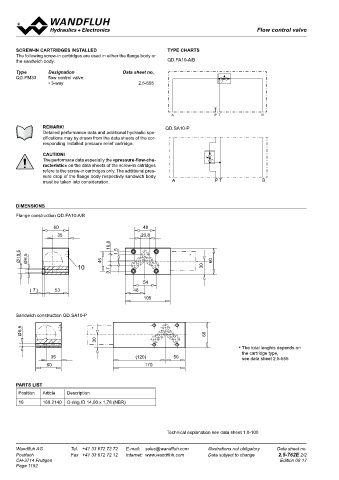

SCREw-IN CARTRIDGES INSTALLED TYPE CHARTS Pressure compensating valve

The following screw-in cartridges are used in either the flange body or Sandwich construction

the sandwich body: QD.FA10-A/B ®

• 2-way operation NG4-Mini

Type Designation Data sheet no. • Q max = 10 l/min

QD.PM33 flow control valve • p = 315 bar

• 3-way 2.5-555 max

DESCRIPTION FUNCTION APPLICATION

Pressure compensator valve with fixed setting The pressure compensator valve maintains a Pressure compensator sandwich valves are

in sandwich design with interface NG4-Mini constant differential pressure through an orifice usually stacked underneath proportional di-

A P T B acc. to Wandfluh standard with 4 ports. The (e.g. metering edge of a directional valve). The rectional valves. They are used in open loop

steel body of the sandwich valve is phospha- 2-way pressure compensator restricts the circuits. 2-way pressure compensators may

REMARK! QD.SA10-P tized and the cartridge body is zinc coated for volume flow in the meter-in mode. be installed in parallel pressure lines with a

Detailed performance data and additional hydraulic spe- corrosion protection. The load is sensed in common power source to operate actuators

cifications may by drawn from the data sheets of the cor- line A or B with an incorporated shuttle valve. individually. For each actuator the full pump

responding installed pressure relief cartridge. pressure is available.

CAUTION!

The performace data especially the «pressure-flow-cha-

racteristic» on the data sheets of the screw-in catridges

refere to the screw-in cartridges only. The additional pres- TYPE CODE

sure drop of the flange body respectivly sandwich body

must be taken into consideration. A P T B U Z F S A04 #

Pressure compensator, 2-way

DIMENSIONS Type of adjustment fixed setting

Flange construction QD.FA10-A/B Sandwich construction

60 48 Mounting interface acc. to Wandfluh standard, NG4-Mini

35 20,8 Design-Index (Subject to change)

16,8

10,5 6,5 1,5 *

Ø Ø 46 60 20 Ø 5.5

10 30

9,7

GENERAL SPECIFICATIONS UZFSA04 HYDRAULIC SPECIFICATIONS

54 Designation 2-way pressure compensating valve Hydraulic fluid Mineral oils, other media on request

40

( 7 ) 53 46 Size NG4-Mini acc. to Wandfluh standard Max. permissible ISO 4406:1999, class 18/16/13

Construction Sandwich construction contamination level (Recommended filter gauge ß6...10≥75)

16

24

105 Mounting 3 mounting holes for M5 socket head screws see data sheet 1.0-50/2

or M5 locking screws Viscosity range 12 mm /s ... 320 mm /s

2

2

Type of connection Thread connection plates Hydraulic fluid temperature -20 ...+70 °C

10

14.2

110

Sandwich construction QD.SA10-P 4.2 Rows of flange plates and horizontal Peak pressure p max = 315 bar

27 stacking system Differential pressure p Diff. = 10 bar

6,5 * Ambient temperature -20…+50 °C Maximum volume flow other differential pressures on request

any

= 10 l/min

Q

Installation position

max

Ø 60 Fastening torque M = 5,5 Nm (Qual. 8.8) for fixing screws Leakage volume flow see characteritics

D

30 P M = 50 Nm for screw cartridge

D

* The total lenghts depends on 40 Weight A m = 1,5 kg

B

the cartridge type, 14 T T0

35 (120) 50 see data sheet 2.5-555 24

60 170

SWITCHING DIAGRAMS MECHANICAL ACTUATION

14

28 Fixed setting design. Other differential pressures available on

PARTS LIST 2-way operation request.

Position Article Description

10 160.2140 O-ring ID 14,00 x 1,78 (NBR)

A P T B A P T B

Technical explanation see data sheet 1.0-100

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.5-762E 2/2 Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.5-820E 1/2

CH-3714 Frutigen A P T B Edition 08 17 CH-3714 Frutigen Edition 21 33

Page 1192

A P T B