Page 1191 - Softbound_Edition_19_en

P. 1191

Flow control valves

Flow control valve

3-way flow control valve

Flange- and sandwich construction NG10

• Q max = 120 l/min ISO 4401-05

• Q N max = 100 l/min

• p max = 350 bar

DESCRIPTION FUNCTION APPLICATION

Direct operated, pressure compensated flow The 3-way flow control valve is designed to 3-way flow control valves are used where the

control valve in flange- and sandwich construc- keep the oil flow to any actuator constant irre- supply volume flow has to be kept constant

tion. Flow control screw-in cartridges M33x2 spectiv of the load. even when the load fluctuates. De-pending on

acc. to ISO 7789 are installed. The flange body the application, a distinction is made between

is painted, the sandwich plates and the outside restricting the forward flow or the return flow.

parts are phosphatised. The solenoid is zinc

coated.

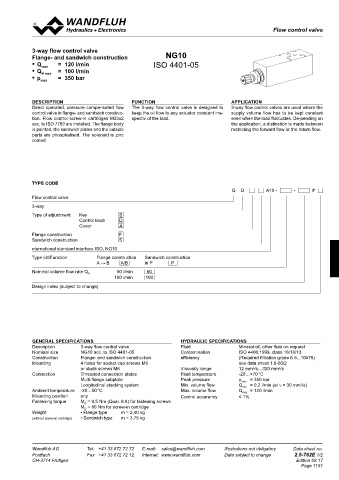

TYPE CODE

Q D A10 - - #

Flow control valve

3-way

Type of adjustment Key S

Control knob D

Cover A

Flange construction F

Sandwich construction S

nternational standard interface ISO, NG10

Type list/Function Flange construction Sandwich construction

A → B A/B in P P

50 l/min 50

Nominal volume flow rate Q N

100 l/min 100

Design index (subject to change)

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

Description 3-way flow control valve Fluid Mineral oil, other fluid on request

Nominal size NG10 acc. to ISO 4401-05 Contamination ISO 4406:1999, class 18/16/13

Construction Flange- and sandwich construction efficiency (Required filtration grade ß 6...10≥75)

Mounting 4 holes for socket cap screws M6 see data sheet 1.0-50/2

or studs screws M6 Viscosity range 12 mm 2 /s…320 mm /s

2

Connection Threaded connection plates Fluid temperature -20…+70 °C

Multi-flange subplate Peak pressure p max = 350 bar

Longitudinal stacking system Min. volume flow Q = 0,2 l/min (at ν = 30 mm /s)

2

min

Ambient temperature -20…50 °C Max. volume flow Q max = 120 l/min

Mounting position any Control accurancy ≤ 1%

Fastening torque M = 9,5 Nm (Qual. 8.8) for fastening screws

D

M = 80 Nm for screw-in cartridge

D

Weight • Flange type m = 2,40 kg

(without screw-in cartridge) • Sandwich type m = 3,75 kg

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.5-762E 1/2

CH-3714 Frutigen Edition 08 17

Page 1191