Page 1167 - Softbound_Edition_19_en

P. 1167

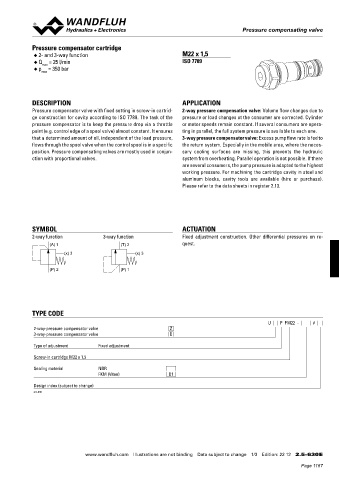

Pressure compensator valve

Flow control valves Pressure compensating valve

CHARACTERISTICS Oil viscosity ν = 30 mm 2 /s Pressure compensator cartridge M22 x 1,5

Q = f (n) Volume flow adjustment characteristics (at p = 350 bar) Q = f (p) Volume flow pressure characteristic ◆ 2- and 3-way function

◆ Q = 25 l/min ISO 7789

max

Q [l/min] Q [l/min] ◆ p = 350 bar

120 K0944_1 120 K0944_2 max

Q = 100 l/min

100 N 100 Q = 100 l/min

N

80 80

60 Q N = 50 l/min 60 Q N = 50 l/min

40 40 DESCRIPTION APPLICATION

20 20 Pressure compensator valve with fixed setting in screw-in cartrid- 2-way pressure compensation valve: Volume flow changes due to

0 0

0 1 2 3 4 n [-] 0 50 100 150 200 250 300 350 p [bar] ge construction for cavity according to ISO 7789. The task of the pressure or load changes at the consumer are corrected. Cylinder

pressure compensator is to keep the pressure drop via a throttle or motor speeds remain constant. If several consumers are opera-

Δp = f (Q) Pressure drop volume flow characteristic 1→ 2 Δp = f (Q) Pressure drop volume flow characteristic 1→ 3 point (e.g. control edge of a spool valve) almost constant. It ensures ting in parallel, the full system pressure is available to each one.

that a determined amount of oil, independent of the load pressure, 3-way pressure compensator valve: Excess pump flow rate is fed to

p [bar] p [bar] flows through the spool valve when the control spool is in a specific the return system. Especially in the mobile area, where the neces-

N

40 K0944_3 15 K0944_4 Q = 50 l/min

position. Pressure compensating valves are mostly used in conjun- sary cooling surfaces are missing, this prevents the hydraulic

30 12 Q N = 100 l/min ction with proportional valves. system from overheating. Parallel operation is not possible. If there

9 are several consumers, the pump pressure is adapted to the highest

20

6 working pressure. For machining the cartridge cavity in steel and

10 3 aluminum blocks, cavity tools are available (hire or purchase).

Please refer to the data sheets in register 2.13.

0 0

0 20 40 60 80 100 120 130 140 Q [l/min] 0 20 40 60 80 100 120 Q [l/min]

DImENSIONS / SECTIONAL DRAWING

Screw adjustment «S» Knob adjustment «D» Cavity drawing acc. to

ISO 7789–33–04–0–98

Ø26 SYMBOL ACTUATION

s3

Ø 17 M33x2 2-way function 3-way function Fixed adjustment construction. Other differential pressures on re-

20 10 (A) 1 (T) 2 quest.

s 10 (x) 3 (x) 3

30

52,3 15 59,8

s36 (3) (P) 2 (P) 1

Ø 40

60

133,05 M 33x2 140,55 (2)

80,75 50 (1)

80 TYPE CODE

U F PM22 - #

70 (1) 2-way-pressure compensator valve Z

40 For cavity details and 3-way-pressure compensator valve D

cavity tools, see data sheet

2.13-1040 Type of adjustment Fixed adjustment

PARTS LIST ACCESSORIES Screw-in cartridge M22 x 1,5

Flange-/sandwich plate NG10 Data sheet 2.5-762

Position Artikcle Description Sealing material NBR

10 1 114.2299 Knob 1 3 Line mount body Data sheet 2.9-210 FKM (Viton) D1

3

15 234.1060 Plate Design index (subject to change)

2

20 193.1040 Safety plate RD4 DIN 6799

2.5-630

30 153.1302 Hexagonal nut 0,5D M6x3,2

2

40 160.2236 O-ring ID 23,52x1,78

50 160.2238 O-ring ID 23,81x2,62

60 160.2298 O-ring ID 29,82x2,62

70 049.3276 Back-up ring RD 24,1x27x1,4

80 049.3297 Back-up ring RD 24,5x29x1,4

Technical explanation see data sheet 1.0-100

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.5-555E 2/2 www.wandfluh.com Illustrations are not binding Data subject to change 1/3 Edition: 22 12 2.5-630 E

CH-3714 Frutigen Edition 10 33

Page 1167