Page 1105 - Softbound_Edition_19_en

P. 1105

Proportional

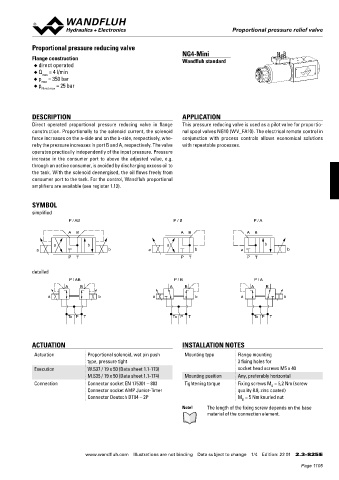

pressure reducing valves Proportional pressure reducing valve

Proportional pressure relief valve

Proportional pressure reducing valve

SCREw-IN CaRTRIDGES INSTallED

The following screw-in cartridges are used in either the flange body or the sandwich REMaRK! Flange construction NG4-Mini

body: Detailed performance data and additional hy- Wandfluh standard

Type Designation Data sheet no. Q max * draulic and electric specifications may by drawn ◆ direct operated

MVPPM22 pilot operated 2.3-629 20 l/min from the data sheets of the corresponding ◆ Q = 4 l/min

max

MQPPM22 pilot operated from connection P 2.3-641 20 l/min installed screw-in cartridge. ◆ p = 350 bar

MVBPM22 pilot operated, explosion proof Ex d 2.3-635 20 l/min p max = 25 bar

MVPPM22-../ME pilot operated, with integr.atedelectronics 2.3-632 20 l/min CaUTION! ◆ N red max

MQPPM22-../ME pilot operated from connection P, 2.3-643 20 l/min The performace data especially the „pressure-

with integrated electronics flow-characteristic„ on the data sheets of

the screw-in catridges refere to the screw-in

cartridges only. The additional press-ure drop

of the flange body respectivly sandwich body DESCRIPTION APPLICATION

* Can deviate from the value on the data sheets of the screw-in cartridges. must be taken into consideration. Direct operated proportional pressure reducing valve in flange This pressure reducing valve is used as a pilot valve for proportio-

** Do not unse anymore for new applications.

construction. Proportionally to the solenoid current, the solenoid nal spool valves NG10 (WV_FA10). The electrical remote control in

TyPE lIST / FUNCTION force increases on the a-side and on the b-side, respectively, whe- conjunction with process controls allows economical solutions

Flange construction: Sandwich construction:

A P red. T B A P T B A P T B reby the pressure increases in port B and A, respectively. The valve with repeatable processes.

A P red. T B A P T 20 B 10 A P T 28 B 30 operates practically independently of the input pressure. Pressure

24 14 increase in the consumer port to above the adjusted value, e.g.

22 through an active consumer, is avoided by discharging excess oil to

A P T B A P T B A red. P T B ∗ A P B G1/4" the tank. With the solenoid deenergised, the oil flows freely from

A P T B 22 A 27 14 P T T B red. 20 40 consumer port to the tank. For the control, Wandfluh proportional

To

A P T B A red. P T B A P T B red. amplifiers are available (see register 1.13).

5,5

9,5

MV.FA04-P/a MV.SA04 - P MV.SA04 - a MV.SA04 - B

Ø Ø 8 32 82 38

A P red. T B A P T B A P T B SYMBOL

40

120

A P red. T B A P T B A P T B

simplified

24 P / AB P / B P / A

22

A P T B A red. P T B P G1/4" A B A B A B

A P T B A P T B ♦ ♦ ∗ A P T A B B red. 40

A red.

A

A

MQ.FA04-P/a MQ.SA04 - P P T B MQ.SA04 - a P T B 22 MQ.SA04 - B P T T B red. 26,8 a b a b

To

a b a b a b

DIMENSIONS 5,5 40 82 38

Ø

Flange construction Sandwich construction in A or B 120 P T P T P T

20 10 28 30 18 detailed

24 14 P / AB P / B P / A

22 P G1/4" A B A B A B

♦ ♦ ∗ A B 40

∗ A P B G1/4" 20 T To 28,5 a b a b a b

27 14 40

22 T To 20 5,5

Ø 40 83 39

9,5 5,5 122 To P T To P T To P T

Ø Ø 8 32 82 38

40 120

For sandwich red. pressure in B cartridge is located on B-side.

Sandwich construction in P

24

22 ACTUATION INSTALLATION NOTES

Actuation Proportional solenoid, wet pin push Mounting type Flange mounting

P

∗ A B G1/4"

♦ ♦ 40 type, pressure tight 3 fixing holes for

22 T To 26,8 Execution W.S37 / 19 x 50 (Data sheet 1.1-173) socket head screws M5 x 40

∗ The envelop dimensions of the screw-in cartridge are shown on

5,5 40 M.S35 / 19 x 50 (Data sheet 1.1-174) Mounting position Any, preferably horizontal

Ø 82 38 their corresponding data sheets.

120 Connection Connector socket EN 175301 – 803 Tightening torque Fixing screws M = 5,2 Nm (screw

D

♦ Distance plate BDP4/... must be ordered separatly. Connector socket AMP Junior-Timer quality 8.8, zinc coated)

18 Connector Deutsch DT04 – 2P M = 5 Nm knurled nut

PaRTS lIST aCCESSORIES D

Proportional amplifier register 1.13 Note! The length of the fixing screw depends on the base

Position Article Description A P B G1/4"

∗

♦ ♦ 40 Distance plate BDP4/12 (12 mm) art. no. 173.1450 material of the connection element.

10 617.3 ... Screw-in cartridge T To 28,5 Distance plate BDP4/20 (20 mm) art. no. 173.1451

20

20 5,5 160.2052 O-ring ID 5,28x1,78 Distance plate BDP4/30 (30 mm) art. no. 173.1452

40

83

30 Ø 238.2406 Plug VSTI G1/4"-ED 39

122

(only flange and sandwich type in P) Technical explanation see data sheet 1.0-100

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.3-820E 2/2 www.wandfluh.com Illustrations are not binding Data subject to change 1/4 Edition: 22 01 2.3-825 E

CH-3714 Frutigen Edition 14 04

Page 1105