Page 1101 - Softbound_Edition_19_en

P. 1101

Proportional Proportional

pressure reducing valves

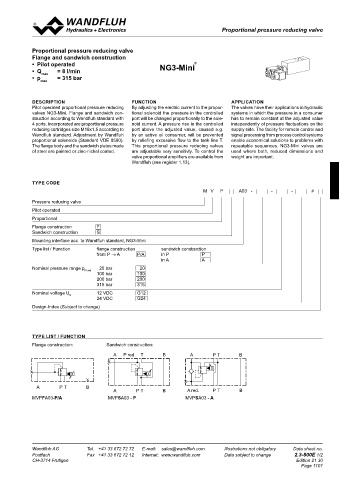

pressure relief valves Proportional pressure reducing valve

SCREW-IN CARTRIDGES INSTALLED Proportional pressure reducing valve

The following screw-in cartridges are used in either the flange body or the sandwich body: Flange and sandwich construction

• Pilot operated ®

Type Designation Data sheet no. Q max * • Q = 8 l/min NG3-Mini

BVPPM22 pilot operated 2.3-529 100 l/min • p max = 315 bar

BNIPM22 pilot operated, inverse 2.3-533 100 l/min max

BVBPM22 pilot operated, explosion proof Ex d 2.3-536 100 l/min

BVPPM22-../ME pilot operated, with integrated electronics 2.3-537 100 l/min

BDPPM22 direct operated 2.3-539 25 l/min

BDBPM22 direct operated, explosion proof Ex d 2.3-547 25 l/min DESCRIPTION FUNCTION APPLICATION

BDPPM22-../ME direct operated, with integrated electronics 2.3-561 25 l/min Pilot operated proportional pressure reducing By adjusting the electric current to the propor- The valves have their applications in hydraulic

valves NG3-Mini. Flange and sandwich con- tional solenoid the pressure in the controlled systems in which the pressure in a consumer

* Can deviate from the values on the data sheets of the screw-in cartridges. struction according to Wandfluh standard with port will be changed proportionally to the sole- has to remain constant at the adjusted value

4 ports. Incorporated are proportional pressure noid current. A pressure rise in the controlled independently of pressure fluctuations on the

reducing cartridges size M18x1,5 according to port above the adjusted value, caused e.g. supply side. The facility for remote control and

Wandfluh standard. Adjustment by Wandfluh by an active oil consumer, will be prevented signal processing from process control systems

GENERAL SPECIFICATIONS proportional solenoids (Standard VDE 0580). by reliefing excessive flow to the tank line T. enable economical solutions to problems with

Description Pilot operated proportional REMARK! The flange body and the sandwich plates made This proportional pressure reducing valves repeatable sequences. NG3-Mini valves are

pressure relief valve Detailed performance data and additional hydraulic and of steel are painted or zinc-nickel coated. are adjustable very sensitivly. To control the used where both, reduced dimensions and

Nominal size NG10 according to ISO 4401-05 electric specifications may by drawn from the data sheets valve proportional amplifiers are available from weight are important.

Constructions Flange or sandwich of the corresponding installed screw-in cartridge. Wandfluh (see register 1.13).

Operations Proportional solenoid

Mounting 4 fixing holes for socket head cap screws

M6 or studs M6 CAUTION! 10 20

Connections Threaded connection plates The performace data especially the „pressure-flow-cha- TYPE CODE 25 20

Multi-flange subplates racteristic„ on the data sheets of the screw-in catridges 15 24 M V P A03 - - 10 - #

Longitudinal stacking system refere to the screw-in cartridges only. The additional press- P G1/8" P G1/8"

Weight: • Flange type m = 2,34 kg ure drop of the flange body respectivly sandwich body must ∅ 7,5 Pressure reducing valve ∗ A B ∗

(without screw-in cartridge) • Sandwich type P, A, B m = 1,70 kg be taken into consideration. ∅ 4,2 T To 30 21 11 T A B To 30

• Sandwich type AB m = 1,94 kg Pilot operated 15 15

Proportional

5,5

24,5

DIMENSIONS Flange construction F 53 72 19 40 63 29

30

Flange construction Sandwich construction in A, B or AB Sandwich construction S 92

10 20 54 Mounting interface acc. to Wandfluh standard, NG3-Mini

48

20 20,8 Type list / Function flange construction sandwich construction

15

P P from P → A P/A in P P

∗ G1/4" ∗ ∗ 14 in A A

A B A B

♦ 60 T To 60 ♦ ♦ 46 T To 26,5 60 P G1/8"

∗

A

38 30 38 41 30 38 Nominal pressure range p N red 20 bar 20 B

∅ 4,2 100 bar T 100 To 30

6,5 200 bar 200 15 20,5

30 40 70 45 B= 1 10

Ø 315 bar 315

70 115 A= 110

AB= 132

Nominal voltage U N 12 VDC 63 G12 29

30

24 VDC 92 G24

Sandwich construction in P Design-Index (Subject to change)

∗ The envelop dimensions of the screw-in cartridge are shown on

∗ P

∗ their corresponding data sheets.

A B

♦ ♦

T To

♦ Distance plate ADP10/... must be ordered separatly.

TYPE LIST / FUNCTION

Flange construction: Sandwich construction:

A P red. T B A P T B A P T B

PARTS LIST ACCESSORIES

Proportional amplifier register 1.13

Position Article Description

Distance plate ADP10/29,5 (29,5 mm) art. no. 173.4456 A P T B

10 160.2140 O-ring ID 14,00 x 1,78 (NBR) A P T B A red. P T B A P T B red.

20 238.2406 Plug VSTI G1/4"-ED MVPFA03-P/A MVPSA03 - P MVPSA03 - A

Technical explanation see data sheet 1.0-100

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.3-760E 2/2 Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.3-800E 1/2

CH-3714 Frutigen Edition 17 01 CH-3714 Frutigen Edition 21 30

Page 1101