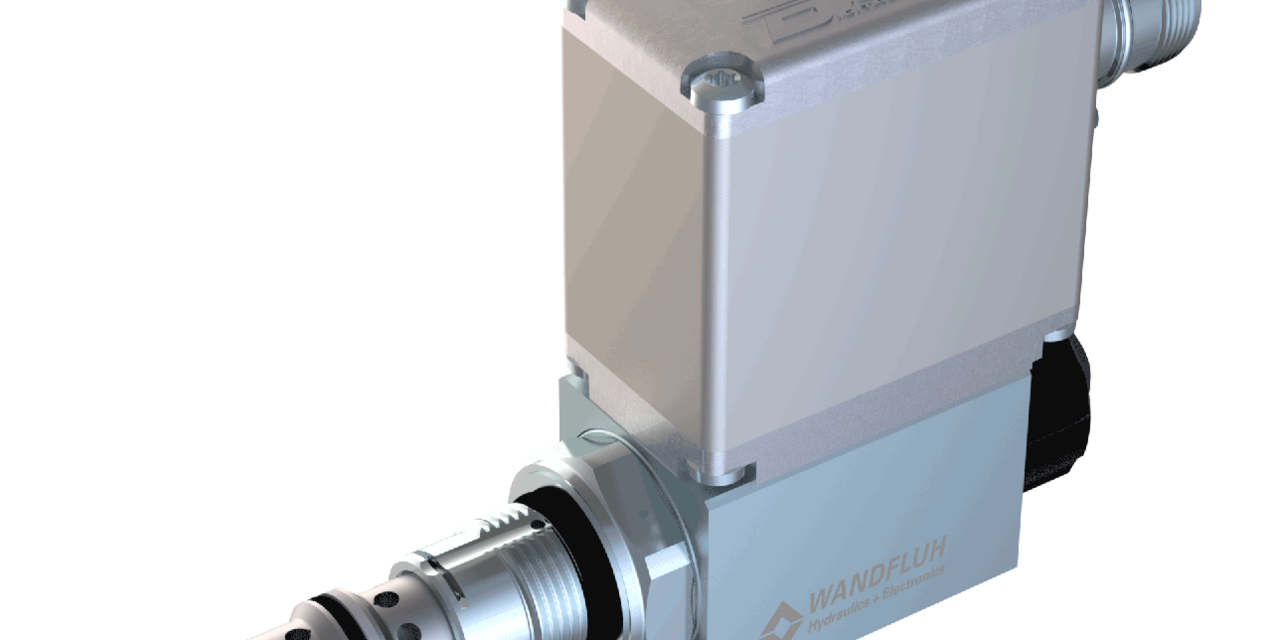

Proportional pressure reducing cartridge pilot operated (slip-on coil, integrated electronics)

Description

Pilot operated proportional pressure reducing valve with integrated electronics in screw-in cartridge construction for cavity according to ISO 7789. Proportionally to the solenoid current, the solenoid force and the pressure in port A (1) rise. The valve functions practically independently of the pressure in port P (2). Pressure increase in the consumer port A (1) to above the adjusted value, e.g. through an active consumer, is avoided by discharging excess oil to the tank T (3). With the solenoid deenergised, the oil flows freely from consumer port A (1) to port T (3). The Plug & Play valves are factory set and adjusted and have therefore a high valve-to-valve reproducibility. The control takes place via an analogue interface or a fieldbus interface (CANopen, J1939 or Profibus DP). The parameterisation takes place by means of the free of cost parameterisation and diagnostics software «PASO» or via fieldbus interface. The USB parameterisation interface is accessible through a screw plug. As an option, these valves are available with integrated controller. As feedback value generators sensors with voltage or current output can be connected directly. The available controller structures are optimised for applications with hydraulic actuations.

Application

Proportional pressure reducing valves with integrated electronics are perfectly suitable for demanding applications in which the pressure frequently has to be changed. They are used in applications where high valve-to-valve reproducibility, easy installation, comfortable operation and high precision are very important. The integrated controller reliefs the machine control and operates the pressure control in a closed loop circuit. The applications are in the industrial as well as in the mobile hydraulics for the smooth control of hydraulic actuations. The screw-in cartridge is perfectly suitable for installation in control blocks and is installed in sandwich- (vertical stacked systems) and in flange plates (corresponding data sheets in this register). For machining the cartridge cavity in steel and aluminum blocks, cavity tools are available (hire or purchase). Please refer to the data sheets in register 2.13.

Key facts

Proportional pressure reducing cartridge with integrated electronics

- pilot operated

- Qmax = 40 l/min

- pmax = 400 bar

- pN red max = 350 bar

Contact us now

Do you have questions about this product or need help finding the best solution for your project? Our network of experienced sales experts is here to support you – personally, competently, and close to you.

To the sales networkDatasheet & downloads

Accessories

Options

Type: PDF

Size: 2 MB

![[Translate to English:] SD73_2 Electronics for hydraulic valve SD73_2](/fileadmin/_processed_/5/7/csm_SD73_2__2a06e8b576.png)