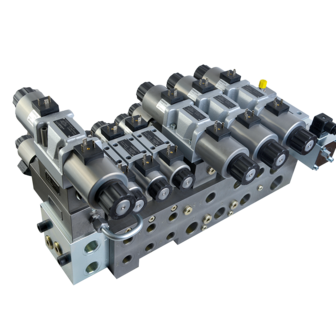

Control units

Based on classic control blocks, modular interlocking systems or monoblocks, our portfolio offers a wide range of electrohydraulic functions in a compact design.

Consulting

Hydraulic control units are the heart of modern drive systems - they precisely control pressure, volume flow and movement sequences. Whether simple functions or complex movement profiles: With our application-oriented advice, we support you from the initial idea to the optimum solution. Together, we select the right control unit, tailored to your requirements in stationary machines, mobile devices or automated systems. The focus is on functionality, energy efficiency, integration and future-proofing.

Thanks to our many years of experience, we develop solutions that can be flexibly adapted - compact, modular and reliable.

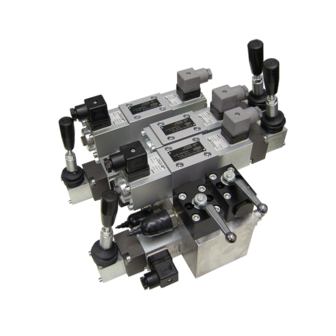

Design & Development

Our experts work with you to analyse your system requirements, define control functions, performance ranges and interfaces, and help you select the ideal components. Whether you need classic valve technology, integrated electronics or tailor-made compact solutions, we work with you to develop a control unit that is precisely tailored to your application.

Our development team accompanies the entire process – from conception to prototyping and test runs to series production. The result is a control unit that guarantees maximum functionality, reliability and durability – precisely tailored to your application.

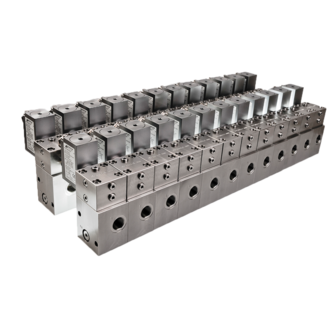

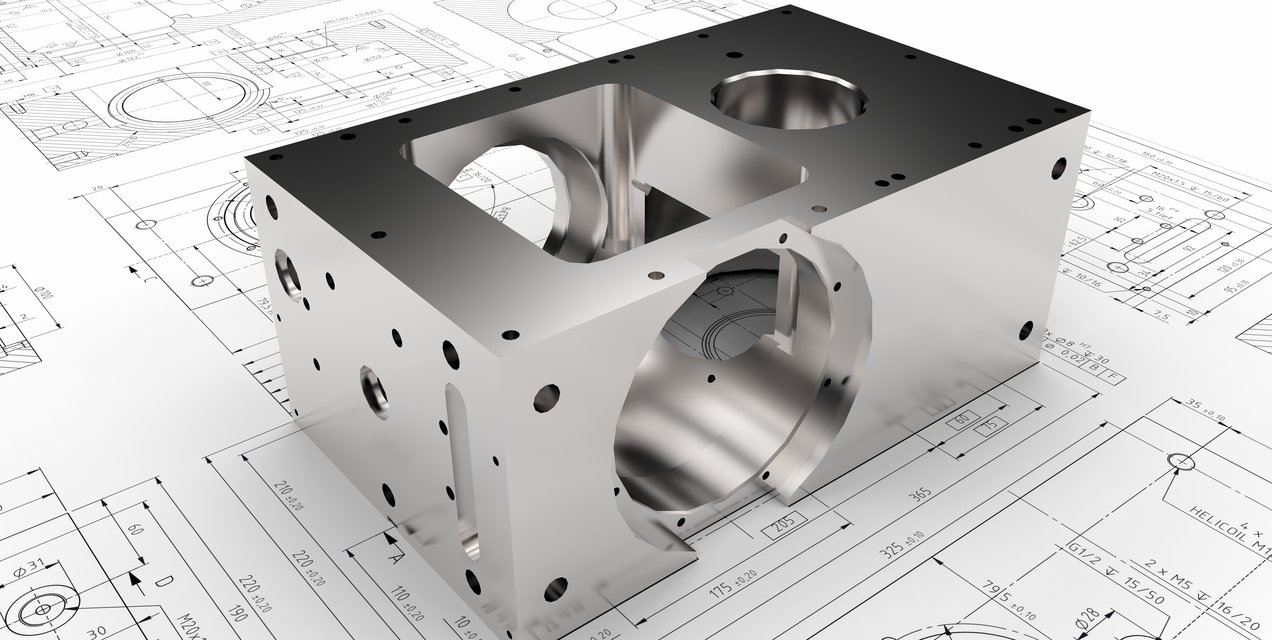

Manufacture

All components – from valve blocks and connection plates to integrated control elements – are manufactured, assembled and tested to fit perfectly in our production facilities. Close integration between development and production means that customer-specific requirements can be implemented directly. Machining on state-of-the-art machining centres ensures precise drilling patterns and clean channel routing,

while experienced specialists take care of the assembly and screw fastening of the units. Each control unit undergoes extensive testing before delivery, including leak, function and pressure tests. The result is a high-quality, reliable and durable control unit that is precisely tailored to your application.

Commissioning

The hydraulic control unit can be easily commissioned by the customer's specialist personnel. All necessary connections, setting options and functions are clearly marked and described in detail in the documentation supplied.

In preparation, the control unit and all hydraulic and electrical connections are installed in accordance with the installation instructions. After connection to the hydraulic system, commissioning is carried out step by step: build up the pressure supply, bleed the system, set the system parameters and carry out a function test. In particular, the control functions, leakage freedom and interaction with the overall unit should be checked.

Kundendienst

Even after commissioning, we are at your side with reliable customer service. If you have any questions, customisation requests or encounter malfunctions during operation, we offer fast and uncomplicated support – by telephone, email or, if desired, via remote access.

Our experienced technicians will assist you with troubleshooting, provide tips for optimisation or help you select the right spare parts. Thanks to well-documented documentation and clear labelling of all components, problems can be solved quickly even without on-site intervention.

For long-term reliability, we also offer maintenance recommendations and service concepts that ensure the reliable operation of your control unit for many years to come.