Page 307 - Softbound_Edition_19_en

P. 307

Spool valve

Spool valve

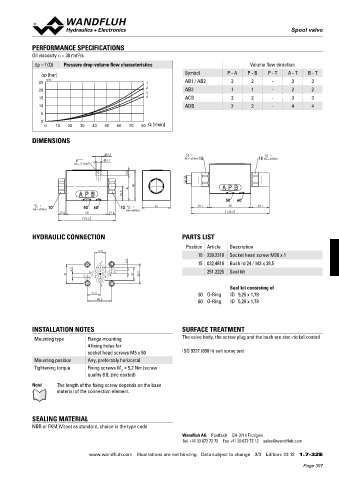

PERFORMANCE SPECIFICATIONS

Oil viscosity u = 30 mm /s

2

Δp = f (Q) Pressure drop-volume flow characteristics Volume flow direction

∆p [bar] Symbol P - A P - B P - T A - T B - T

25 K4256 1 AB1 / AB2 2 2 - 3 3

20 2 AB3 1 1 - 2 2

3

15 4 ACB 2 2 - 3 3

10 ADB 2 2 - 4 4

5

0

0 10 20 30 40 50 60 70 80 Q [l/min]

DIMENSIONS

9.5

5.2 MD=60Nm15 15 MD=60Nm

MD= 5.2Nm

8

G1/4"

41 49

23.5

50 60

10 50 60 10 46 30.1 68 30.1

MD=60Nm MD=60Nm

12.6 68 12.6 128.2

93.2

HYDRAULIC CONNECTION PARTS LIST

Position Article Description

17.8

10 239.2210 Socket head screw M20 x 1

T 6.5 15 032.4818 Bush rd 24 / M3 x 38,5

6.5 251.2225 Seal kit

31 x A B y 21 32.5

P

Seal kit consisting of

21.5 50 O-Ring ID 9,25 x 1,78

40.5 60 O-Ring ID 5,28 x 1,78

INSTALLATION NOTES SURFACE TREATMENT

Mounting type Flange mounting The valve body, the screw plug and the bush are zinc-nickel coated

4 fixing holes for

socket head screws M5 x 50 ISO 9227 (800 h) salt spray test

Mounting position Any, preferably horizontal

Tightening torque Fixing screws M = 5,2 Nm (screw

D

quality 8.8, zinc coated)

Note! The length of the fixing screw depends on the base

material of the connection element.

SEALING MATERIAL

NBR or FKM (Viton) as standard, choice in the type code

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

www.wandfluh.com Illustrations are not binding Data subject to change 3/3 Edition: 23 12 1.7-32 E

Page 307