Page 27 - Softbound_Edition_19_en

P. 27

Solenoids Solenoids

Solenoid

CHARACTERISTICS DC AC Proportional solenoid PI29V

Static pressure tightness 350 bar (seal diameter of valve Totale stroke (mm) 2,5 2,5 to VDE 0580

max. 15 mm) Working stroke (mm) 1 1 Plug plate to ISO 4400 / DIN 43650

With seal diameter of valve = 27 mm: Nominal power (W) 15

Static pressure tightness = 100 bar (VA) 17 Protection class IP65

Coil winding insulation class H Armature weight (kg) 0,014 0,014

Connection / Power supply Over device plug connection to Solenoid weight (kg) 0,21 0,21

ISO 4400 / DIN 43650,(2P+E), Voltage range (VDC) 10-250

other connections on request (VAC) 24-250

Protection class to EN 60 529 IP65 DESCRIPtION fuNCtION APPLICAtION

Relative duty factor 100 % The PI29V is a proportional solenoid. Its design The horizontal force-stroke characteristics in Essential for hydraulic proportional-way-,

Reference temperature 50 °C corresponds to VDE standard 0580. The steel the working stroke range means that: pressure- and current valves. Because of the

Seal Viton, other on request housing is zinc coated as a standard. Static – a more or less linear force absorption can be risk of overheating, the solenoid must never be

Fluid Mineral oil, other fluid on request pressure tightness is 350 bars. All o-rings are achieved with constant stroke and increasing used separately. The lenght of the fixing screws

Switching cycles 15 000/h 12VDC 24VDC 115VAC 230VAC Viton. The solenoids are fixed to the valve current absorption; depends on the base material of the body. An

Mounting screws 4 x M3 (Quality 8.8) Nominal resistance (Ω) 10 42 650 2’650 with four screws. Depending on the intended – a more or less linear stroke variation can be o-ring is used for the valve seal. Information

Housing Zinc coated steel housing, Number of windings (-) 740 1’490 5’800 11’000 use, the solenoid can be supplied with a plug achieved when working against a spring and on screws and o-rings will be found in the

other surface treatments on request. Inductivity (mH) 17 70 - - screw, or with integrated manual override. The with increasing current absorption. data sheets relating to the valves concerned.

connector plate corresponds to ISO 4400 and This ensures that the reference voltage is ade- Before changing the plug screw or the screw

DIN 43650. quate at the specified reference temperature to with integrated manual override, care must

reach the limit current in every case. be taken to ensure that the solenoid is not

under pressure. Risk of injury! The maximum

operating pressure is determinded by the valve

actually used.

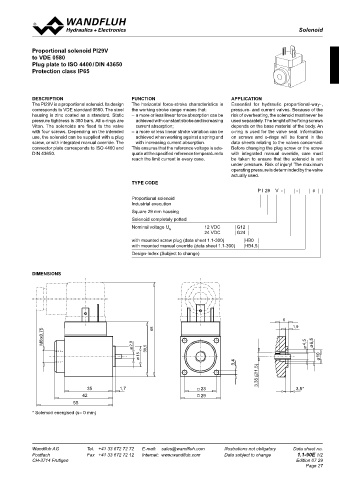

tYPE CODE

P I 29 V - - #

PERfORMANCE ACCESSOIRES Proportional solenoid

Industrial execution

F = f (s) Force-stroke characteristics Plug HB0 ∗ Article No. 239.2033 Square 29 mm housing

F [N] Plug with integrated manual override HB4,5 ∗ Article No. 253.8000

70 K0056 ∗ acc. data sheet 1.1-300 Solenoid completely potted

Nominal voltage U 12 VDC G12

N

Special manual override see data sheet 1.1-310 24 VDC G24

60 with mounted screw plug (data sheet 1.1-300) HB0

Plug grey Article No. 219.2001 with mounted manual override (data sheet 1.1-300) HB4,5

Plug black Article No. 219.2002

50 Design-Index (Subject to change)

40

DIMENSIONS

30

1

20

2

10

6

1,9

0 8x0,75 68

0 0,5 1,0 1,5 2,0 2,5 s [mm]

M 2,9 4,5 6,5

39,5

15 10

1: U = 100 % U N Reference temperature = 20 °C (15W)

2: U = 90 % U Reference temperature = 50 °C 3,4

N

Solenoid in operating temperature (9W)

The values refer to U = 24VDC. 3,35 (∅1,5)

N

With other nominal voltages deviations can occur. 35 1,7 23 3,5*

For curve 2 the solenoid has been mounted on a body 30 x 38.

42 29

55

* Solenoid energised (s= 0 mm)

Technical explanation see data sheet 1.1-400

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 1.1-85E 2/2 Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 1.1-90E 1/2

CH-3714 Frutigen Edition 05 01 CH-3714 Frutigen Edition 07 29

Page 27