Page 240 - Softbound_Edition_19_en

P. 240

Solenoid operated spool valve

Solenoid operated spool valve Solenoid operated spool valve

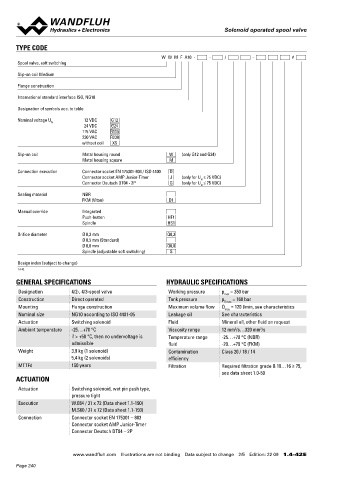

TYPE CODE ELECTRICAL SPECIFICATIONS MANUAL OVERRIDE

W W M F A10 - - / - # Protection class Connection execution D: IP65 ◆ Integrated (–) Actuation pin integrated in the armature tube.

Spool valve, soft switching Connection execution J: IP66 Actuation by pressing the pin

Connection execution G: IP67 and IP69K ◆ Push-button (HF1) Integrated in the knurled nut. Actuation by

Slip-on coil Medium pressing the push-button

Relative duty factor 100 % DF

Flange construction Switching frequency Since switching is damped and slow, ◆ Spindle (HS1) Integrated in the knurled nut. Actuation by turning

the spindle (continuously variable valve actuation)

switching frequency is of secondary

International standard interface ISO, NG10 Attention! The actuation of the manual override is possible up to a

importance.

7

Designation of symbols acc. to table Service life time 10 (number of switching cycles, tank pressure of:

20 bar Integrated (–)

theoretically) 20 bar Push-button (HF1)

Nominal voltage U 12 VDC G12 Voltage tolerance ± 10 % with regard to nominal voltage 80 bar Spindle (HS1)

N

24 VDC G24

115 VAC R115 Standard nominal 12 VDC, 24VDC, 115 VAC, 230 VAC

230 VAC R230 voltage AC = 50 to 60 Hz, rectifier integrated in

without coil X5 the connector socket

Slip-on coil Metal housing round W (only G12 and G24) Note! Other electrical specifications see data sheet 1.1-190

Metal housing square M (slip-on coil W) and 1.1-193 (slip-on coil M)

Connection execution Connector socket EN 175301-803 / ISO 4400 D

Connector socket AMP Junior-Timer J (only for U ≤ 75 VDC)

N

Connector Deutsch DT04 - 2P G (only for U ≤ 75 VDC)

N

COMMISSIONING SURFACE TREATMENT

Sealing material NBR ◆ The valve body is painted with a two component paint

FKM (Viton) D1 Attention! When commissioning, the valve must be vented under

pressure (max. two rotations of screw E). ◆ The screw plug is zinc-nickel coated

Manual override Integrated ◆ The slip-on coil and the armature tube are zinc-nickel coated

Push-button HF1

Spindle HS1

Orifice diameter Ø 0,3 mm Q0,3 STANDARDS SEALING MATERIAL

Ø 0,5 mm (Standard) Mounting interface ISO 4401-05 NBR or FKM (Viton) as standard, choice in the type code

Ø 0,8 mm Q0,8

Spindle (adjustable soft switching) S Solenoids DIN VDE 0580

Connection execution D EN 175301 – 803

Design index (subject to change) Protection class EN 60 529

1.4-42

Contamination efficiency ISO 4406

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

Designation 4/2-, 4/3-spool valve Working pressure p = 350 bar

max

Construction Direct operated Tank pressure p = 160 bar ACCESSORIES INSTALLATION NOTES

T max

Mounting Flange construction Maximum volume flow Q = 120 l/min, see characteristics

max Mating connector grey (A) Article no. 219.2001 Mounting type Flange mounting

Nominal size NG10 according to ISO 4401-05 Leakage oil See characteristics Mating connector black (B) Article no. 219.2002 4 fixing holes for

Actuation Switching solenoid Fluid Mineral oil, other fluid on request socket head screws M6 x 40

Ambient temperature -25…+70 °C Viscosity range 12 mm /s…320 mm /s Fixing screws Data sheet 1.0-60 Mounting position Any, preferably horizontal

2

2

if > +50 °C, then no undervoltage is Temperature range -25…+70 °C (NBR) Threaded subplates Data sheet 2.9-30 Tightening torque Fixing screw

admissible fluid -20…+70 °C (FKM) Multi-station subplates Data sheet 2.9-60 M = 10,5 Nm ± 10 % (screw quality 8.8,

D

Weight 3,9 kg (1 solenoid) Contamination Class 20 / 18 / 14 Horizontal mounting blocks Data sheet 2.9-100 zinc coated)

5,4 kg (2 solenoids) efficiency Technical explanations Data sheet 1.0-100 max. tank pressure 80 bar

MTTFd 150 years Filtration Required filtration grade ß 10…16 ≥ 75, Filtration Data sheet 1.0-50 M = 13,5 Nm ± 10 % (screw quality 10.9,

D

see data sheet 1.0-50 zinc coated)

ACTUATION Relative duty factor Data sheet 1.1-430 Knurled nut M = 5 Nm

D

Actuation Switching solenoid, wet pin push type, Note! The length of the fixing screw depends on the base

pressure tight material of the connection element.

Execution W.E64 / 31 x 72 (Data sheet 1.1-190)

M.S60 / 31 x 72 (Data sheet 1.1-193)

Connection Connector socket EN 175301 – 803

Connector socket AMP Junior-Timer

Connector Deutsch DT04 – 2P

www.wandfluh.com Illustrations are not binding Data subject to change 2/5 Edition: 22 09 1.4-42 E www.wandfluh.com Illustrations are not binding Data subject to change 3/5 Edition: 22 09 1.4-42 E

Page 240