Page 1032 - Softbound_Edition_19_en

P. 1032

Proportional pressure reducing valve

Proportional pressure reducing valve Proportional pressure reducing valve

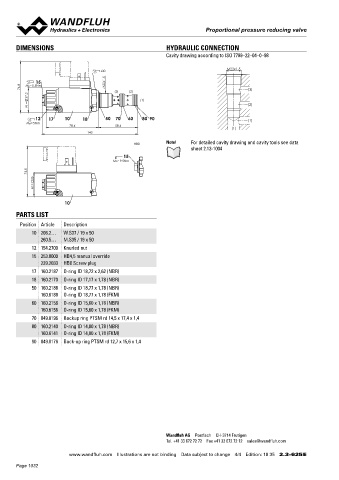

DIMENSIONS HYDRAULIC CONNECTION Proportional pressure reducing cartridge

Cavity drawing according to ISO 7789–22–04–0–98 ◆ direct operated by means of pilot spool M22 x 1,5

◆ Q = 20 l/min ISO 7789

max

M22x1.5 ◆ p = 350 bar

s30 max x II 2 G Ex db IIC T6, T4

◆ p N red max = 200 bar

15 M22x1.5 x II 2 D Ex tb III C T80 °C, T130 °C

76.8 MD=5.5Nm (3) (2) (3) x I M2 Ex db I Mb

37.2 Class I Division 1

(1) Class I Zone 1

W = (2)

12 17 10 18 50 70 60 80 90 (1)

DESCRIPTION

MD=5Nm APPLICATION

78.4 58.4

(1)

143 Direct operated proportional pressure reducing valve with pilot These valves are suitable for applications in explosion-hazard

spool actuation in screw-in cartridge construction for cavity areas, open cast and also in mines. The electrical remote control in

HB0 Note! For detailed cavity drawing and cavity tools see data according to ISO 7789. Proportionally to the solenoid current, the conjunction with process controls allows economical solutions

sheet 2.13-1004 solenoid force and the pressure in port A (1) rise. The valve func- with repeatable processes. The screw-in cartridge is perfectly sui-

15 tions practically independently of the pressure in port P (2). Pres- table for installation in control blocks and is installed in sandwich-

MD= 9.5Nm

sure increase in the consumer port A (1) to above the adjusted (vertical stacked systems) and in flange plates (corresponding data

74.8 value, e.g. through an active consumer, is avoided by discharging sheets in this register). For machining the cartridge cavity in steel

M = □35 excess oil to the tank T (3). With the solenoid deenergised, the oil and aluminum blocks, cavity tools are available (hire or purchase).

flows freely from consumer port A (1) to port T (3). For the control,

Please refer to the data sheets in register 2.13.

Wandfluh proportional amplifiers are available (see register 1.13).

The pressure tight encapsulated Ex-protection solenoid coil pre-

10

vents an explosion on the inside penetrating to the outside as well

PARTS LIST as an ignitable surface temperature.

Position Article Description

10 206.2… W.S37 / 19 x 50

260.5… M.S35 / 19 x 50 TYPE CODE

12 154.2700 Knurled nut M P B PM22 - - / / - #

15 253.8000 HB4,5 manual override Pressure reducing valve

239.2033 HB0 Screw plug

Direct operated by means of pilot spool

17 160.2187 O-ring ID 18,72 x 2,62 (NBR)

18 160.2170 O-ring ID 17,17 x 1,78 (NBR) Proportional, explosion proof execution Ex d

50 160.2188 O-ring ID 18,77 x 1,78 (NBR) Screw-in cartridge M22 x 1,5

160.6188 O-ring ID 18,77 x 1,78 (FKM)

60 160.2156 O-ring ID 15,60 x 1,78 (NBR) Execution L9 L15 / L17

160.6156 O-ring ID 15,60 x 1,78 (FKM) Nominal pressure range p [bar] 20 115 20 135

N

80

200

235

95

70 049.8196 Backup ring PTSM rd 14,5 x 17,4 x 1,4

Nominal voltage U 12 VDC G12

80 160.2140 O-ring ID 14,00 x 1,78 (NBR) N 24 VDC G24

160.6141 O-ring ID 14,00 x 1,78 (FKM)

90 049.8176 Back-up ring PTSM rd 12,7 x 15,6 x 1,4 Ambient temperature up to:

Nominal power P 9 W L9 40 °C or 90 °C

N

15 W L15 70 °C

17 W L17 70 °C (only UL / CSA)

Certification ATEX, IECEx, EAC,

CCC UL / CSA UL

Australia AU MA (nur L15) MA

Sealing material NBR

FKM (Viton) D1

Options without

amplifier M248

Design index (subject to change)

2.3-627

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 18 35 2.3-625 E www.wandfluh.com Illustrations are not binding Data subject to change 1/4 Edition: 21 21 2.3-627 E

Page 1032