Page 1030 - Softbound_Edition_19_en

P. 1030

Proportional pressure reducing valve

Proportional pressure reducing valve Proportional pressure reducing valve

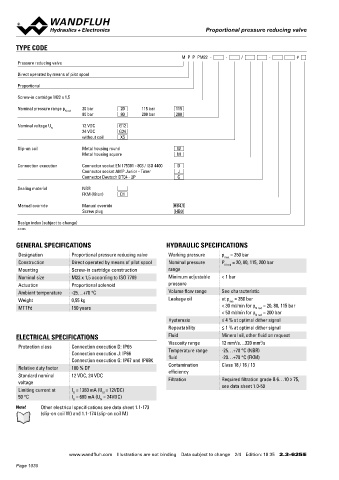

TYPE CODE PERFORMANCE SPECIFICATIONS

2

M P P PM22 - - / - # Oil viscosity u = 30 mm /s

Pressure reducing valve p =f (Q) Pressure volume flow characteristic p =f (Q) Pressure volume flow characteristic

Maximal adjustable pressure Minimal adjustable pressure

Direct operated by means of pilot spool

p [bar] p [bar]

Proportional K4167 K4168

300 100

90

Screw-in cartridge M22 x 1,5 250 80

200 p N red = 200 bar 70

60

Nominal pressure range p N red 20 bar 20 115 bar 115 150 50

80 bar 80 200 bar 200 100 p N red = 115 bar 40

30

p N red = 80 bar

50 20

Nominal voltage U 12 VDC G12 p N red = 20 bar 10

N 0 0

24 VDC G24 25 20 15 10 5 0 5 10 15 20 25 25 20 15 10 5 0 5 10 15 20 25

without coil X5 A T Q [l/min] P A A T Q [l/min] P A

Slip-on coil Metal housing round W

Metal housing square M p =f (I) Pressure adjustment characteristics

Bis I = 40 % leicht erhöhte Hysterese

Connection execution Connector socket EN 175301 - 803 / ISO 4400 D G

Connector socket AMP Junior - Timer J p [bar]

red

Connector Deutsch DT04 - 2P G 200 K4169 p N red = 200 bar

180

Sealing material NBR 160

140

FKM (Viton) D1 120 p N red = 115 bar

100

80 p N red = 80 bar

Manual override Manual override HB4,5 60

Screw plug HB0 40

20 p N red = 20 bar

0

Design index (subject to change) 0 10 20 30 40 50 60 70 80 90 100 I [%]

2.3-625

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

Designation Proportional pressure reducing valve Working pressure p = 350 bar

max

Construction Direct operated by means of pilot spool Nominal pressure P N red = 20, 80, 115, 200 bar ACCESSORIES MANUAL OVERRIDE

Mounting Screw-in cartridge construction range Proportional amplifier Register 1.13 HB4,5

Nominal size M22 x 1,5 according to ISO 7789 Minimum adjustable < 1 bar Electric plug B (black) Article no. 219.2002 Optionally: Screw plug (HB0), no actuation possible

Actuation Proportional solenoid pressure Technical explanations Data sheet 1.0-100

Ambient temperature -25…+70 °C Volume flow range See characteristic Hydraulic fluids Data sheet 1.0-50

Weight 0,55 kg Leakage oil at p = 350 bar

sys

MTTFd 150 years < 30 ml/min for p N red = 20, 80, 115 bar Filtration Data sheet 1.0-50

< 50 ml/min for p = 200 bar

N red

Hysteresis ≤ 4 % at optimal dither signal

Repeatability ≤ 1 % at optimal dither signal

ELECTRICAL SPECIFICATIONS Fluid Mineral oil, other fluid on request

Viscosity range 12 mm /s…320 mm /s

2

2

Protection class Connection execution D: IP65

Connection execution J: IP66 Temperature range -25…+70 °C (NBR) SURFACE TREATMENT SEALING MATERIAL

Connection execution G: IP67 and IP69K fluid -20…+70 °C (FKM)

Relative duty factor 100 % DF Contamination Class 18 / 16 / 13 ◆ The cartridge body, the slip-on coil and the armature tube are NBR or FKM (Viton) as standard, choice in the type code

zinc-nickel coated

efficiency

Standard nominal 12 VDC, 24 VDC Filtration Required filtration grade ß 6…10 ≥ 75,

voltage see data sheet 1.0-50

Limiting current at I = 1360 mA (U = 12VDC)

G

N

50 °C I = 680 mA (U = 24VDC)

G N

Note! Other electrical specifications see data sheet 1.1-173

(slip-on coil W) and 1.1-174 (slip-on coil M)

www.wandfluh.com Illustrations are not binding Data subject to change 2/4 Edition: 18 35 2.3-625 E www.wandfluh.com Illustrations are not binding Data subject to change 3/4 Edition: 18 35 2.3-625 E

Page 1030