Page 5 - Mobile_EN_WEB

P. 5

APPLICATION FUNCTION

An electric high mast truck is a typical example of a hydrau-

POTATO HARVESTER lic lifting and lowering application. Lifting is usually carried

out directly via the built-in hydraulic pump, as the load coun-

teracts the direction of movement. For a controllable and

gentle lowering function, appropriate hydraulic valves are

used, which allow the oil to flow back into the tank in a con-

Potato harvesting is a globally essential process in the trolled manner via a bypass. In simple systems, this task

agricultural industry. To efficiently and effectively harvest is performed by a classic poppet valve. For more complex

undamaged potatoes, the use of a potato harvester hy- applications with increased requirements, load-compensa- COMPONENTS

ted proportional valves or load-compensated flow regulators

draulic system is crucial and plays a vital role in various are used. The design of the valve ensures that the lowering Various valves are available for the lowering movement.

aspects of the harvesting process where it is responsible speed is kept constant regardless of the load. These valves • Soft-closing poppet valve S2206-S1841

for powering the different components of the harvester, are also available in a seattight design. This ensures that

the fork remains in position when deenergized and does not

such as the motors, conveyors, diggers, ploughshears slowly lower due to leakage. • Proportional throttle valves DNPPM22 (25LPM) and DN-

PPM33 (63LPM)

(cutting blades) and separators while precisely adjusting

the machines operation to compensate for conditions • Load-compensated flow control valves QNPPM22 and

QNPPM33

and products being farmed.

• Leak-free flow control valves QSPPU10 and QSPPM33

These all-in-one valves control the lowering speed inde-

pendently of the load and are tight when deenergized. The

fork remains in position.

FUNCTION APPLICATION SPECIALTIES

The hydraulic system offers high power density and contribu- • With heavy loads, the system can tend to oscillate (boun-

tes significantly to the overall efficiency of the potato harves- cing effect), which can be absorbed and corrected with

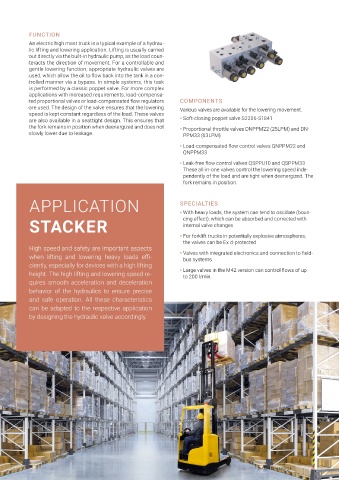

ter, generating significant force and torque, enabling efficient STACKER internal valve changes

digging and the smooth lifting of potatoes from the ground

in various soil conditions, ensuring reduced bruising and a • For forklift trucks in potentially explosive atmospheres,

thorough and successful harvest. the valves can be Ex d-protected

Its ability to control and transmit the required speed and High speed and safety are important aspects • Valves with integrated electronics and connection to field-

power through precision low loss hydraulic valve products when lifting and lowering heavy loads effi- bus systems

allows for the design of smaller, more compact and light- ciently, especially for devices with a high lifting

weight machines, reducing energy consumption and increa- • Large valves in the M42 version can control flows of up

sing maneuverability, making the harvester more productive height. The high lifting and lowering speed re- to 200 l/min.

and cost-effective. quires smooth acceleration and deceleration

COMPONENTS behavior of the hydraulics to ensure precise

At the heart of the system are high quality hydraulic elec- and safe operation. All these characteristics

tro-proportional or ON/OFF valves that direct flow and pro-

portional or pre-set pressure valves for system safety or to can be adapted to the respective application

control the force needed for successful operation of a ma- by designing the hydraulic valve accordingly.

chine function. These valves can be flange or screw-in car-

tridge format, typically mounted in a manifold assembly or

provided as a sectional valve such as the Higher flow PMV or

the CMV(A) suited for lower flows and pressures.

SPECIALTIES

• Pilot flow to large flow control valves for cylinders, motors,

brakes etc.

• Full electro-hydraulic control of ON/OFF and proportional

products for remote control

• Mobile MD2 electronics interface to SAE J1939 data on

PTO RPM’s, and sensors

• Parameterization software for commissioning and

maintenance

4 WANDFLUH MOBILE WANDFLUH MOBILE 5