Features

Compared to conventional slip-in valves or to competitor products on the hydraulics market, the C_ENxx 2-way cartridge valves are characterised by the following features:

In applications above a certain size, such as in aluminum processing in the form of casting presses with holding pressure systems, in the opening mechanisms of large ship hatches, in large goods lifts or cranes, powerful hydraulic systems are required. In order to handle these demanding tasks at an efficient speed, a correspondingly powerful valve technology is required that provides precise control and sensitivity despite the high flow rates.

Contact us for more information on product details, prices and short delivery times.

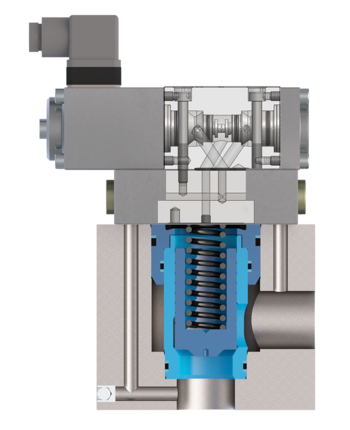

2-way slip-in cartridge valves are particularly compact logic elements for block design. They make it possible to realise a multitude of hydraulic functions for a high-flow application in the smallest possible space within a control block. During the design of the new valve series, state-of-the-art flow simulation software was then also used, which led to an optimised geometry of the valves. Thanks to the new valve design, it was possible to practically double the flow rate with the same pressure loss Δp compared to the previous models.

The range of 2-way slip-in cartridge valves in the nominal sizes NG16, NG25, NG32, NG40 has been extended by an additional nominal size NG50. This series is characterised by a three-piece design, which results in a higher pressure resistance. The new series is then also approved for a system pressure of up to 630 bar (9,000 psi) in operation, as used in applications such as presses or die casting systems. This significantly higher power density of the new valves ultimately makes it possible to build even more compactly and to plan with a smaller nominal size when designing a hydraulic circuit. The result is even smaller, more efficient and above all significantly lighter control blocks compared to the previous market.

With the new series from Wandfluh, hydraulic logic modules with a system pressure of 630 bar and up to a maximum flow rate of 2.360 l/min (at ∆p of 5 bar) can be combined in one block to form a complex circuit while saving space and weight. The modular design of the individual valve parts and the use of suitable cover and pilot valve combinations allow a wide range of different functions. Thanks to the low pressure drop ∆p, this type of circuit is very efficient and, compared to a conventional hydraulic solution, has few interfaces where leakage to the outside would be possible at all.

| Designation | Pressure | Flow |

|---|---|---|

| C_EN16 | 630 bar | 270 l/min |

| C_EN25 | 630 bar | 600 l/min |

| C_EN32 | 630 bar | 980 l/min |

| C_EN40 | 630 bar | 1,620 l/min |

| C_EN50 | 630 bar | 2,360 l/min |

Volume flow data at ∆p of 5 bar

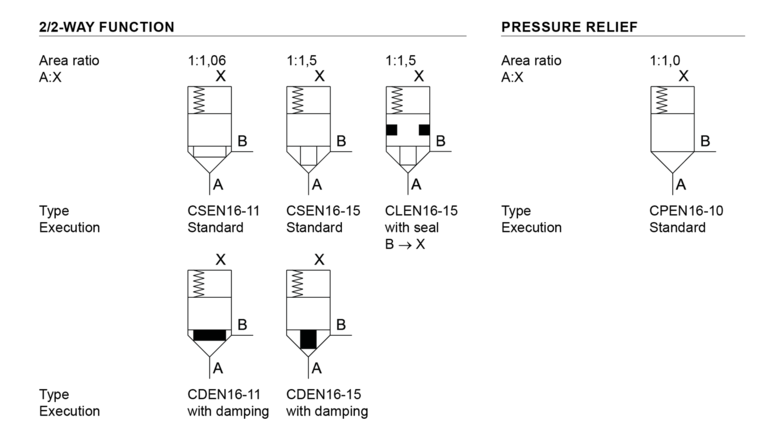

The valves are available in two different basic versions: the seat-tight switching function and the pressure function. The switching function is available with different opening ratios and can be supplemented by pistons with non-return function, damping nose and/or seal. Due to the modular design of the individual valve parts and the use of corresponding cover and pilot valve combinations, it is possible to obtain a wide range of different functions. These include, for example, spool valves with start, stop and directional control or pressure valves for pressure limitation, pressure relief, pressure sequence and unloading function or non-return valves.

The various "functions", "Area ratio" and "Type executions" can be found on the individual data sheets.

The bore with the 2-way slip-in valve is covered with a control cover. On it is a pilot valve that determines the function of the hydraulic circuit. Due to the wide variety of hydraulic systems in the different fields of application, there is a large selection of pilot valves. These range from simple throttle valves to damped flow control valves and load-compensated, seat-tight flow control valves. A large selection of proportional valves can also ensure sensitive lifting and lowering of heavy loads in any operating mode.

Compared to conventional slip-in valves or to competitor products on the hydraulics market, the C_ENxx 2-way cartridge valves are characterised by the following features:

Mobile

Offshore

Metal and plastic casting

Bending and pressing

2-way cartridge valves are typically used in various applications where high hydraulic performance is required in a limited space. They can be very easily integrated into a control block and driven via a pilot valve with individual function. A special feature of these new C_ENxx 2-way cartridge valves is the low pressure loss even at very high flow rates.