The basic modules with a modular control design

The term basic systems describes the basic modules with a modular control design and also serial powerpacks. In a customer-specific design and construction, these are mainly used in industrial machinery. Both product types are manufactured in large numbers and at interesting prices.

Basic modules

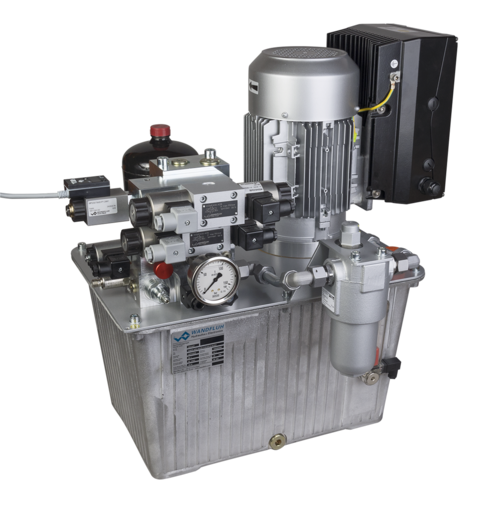

Wandfluh has launched a new line of energy-efficient powerpacks. The big difference between these energy-efficient powerpacks/basic modules and other commercially available hydraulic powerpacks is the conception of the interface which for the customer-specific circuit set-up can either be arranged directly on the powerpack, or in a decentral location. As a result, from a basic module and a customer-specific design, a system solution especially tailored to the customer's needs is realised.

In order to offer excellent functionality, energy efficiency, small space requirement, durability and reliability at low costs, a customer-specific hydraulic system is often designed using basic modules from the BM standard line.

The core element of the newly developed powerpack/basic modules is an intelligent basic control unit with an integrated economy circuit. The design basically consists of an electric motor, a hydraulic pump, filter units, and a pressure accumulator. For the calculation and the development of the basic control unit and the choice of the electric motor, special attention is paid to energy efficiency.

Up to 80 % energy savings thank to intelligent circuits

Due to the new, intelligent circuit diagram for the basic control unit, the motor operating time can be considerably reduced compared with the conventional accumulator unloading operation. This leads to significant energy savings of up to 80 % during operation. And in addition to the improved circuit diagram of the basic control unit, the new basic modules can optionally be equipped with a process-controlled frequency converter which leads to a further substantial improvement of the energy balance.

CHN Standard powerpack line

The proven CHN standard powerpack line remains part of the programme. It is also available as a ATEX execution. With tank volumes of up to 60 l, a pump flow rate of up to 25.5 l/min, and motor power of up to 7.5 kW, these powerpacks cover a broad spectrum.

BM-Compact4 Standard powerpack

The BM-Compact4 powerpack is often used for tensioning or clamping functions in milling machines. Due to its cost-optimised and compact construction it is suited for a wide variety of machine types. On the intelligent basic control unit with passive energy-saving circuit, the required valve circuits are installed, tested and delivered on a modular basis by the Wandfluh assembly personnel in a very short time.

| Tank volume | 6.3 l |

| Motor power | 0.18 … 0.75 kW |

| Pump flow rate | Up to 2.8 l/min |

| Basic control unit | Compact NG4 |

| Filtration | 6 µm |

| spin-on return filter |

BM-Compact6 Standard powerpack

The BM-Compact6 powerpack is often used for quick tensioning or clamping functions in machine tools. Due to its cost-optimised and compact construction, it is suited for a wide variety of machine types. On the intelligent basic control unit with passive energy-saving circuit, the required valve circuits are installed, tested and delivered on a modular basis by the Wandfluh assembly personnel in a very short time.

| Tank volume | 10.0 l |

| Motor power | 0.25 … 1.5 kW |

| Pump flow rate | Up to 10.0 l/min |

| Basic control unit | Choice of Compact NG4 or Flex NG6 |

| Filtration | 6 µm |

| spin-on return filter |

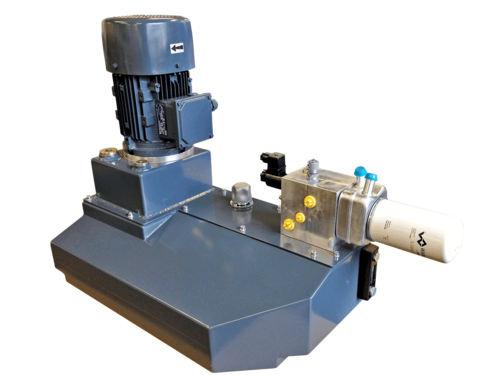

BM-Flex6 Standard powerpack

The BM-Flex 6 powerpack can be used with great flexibility in a wide variety of machine tools. This is ultimately a 10 l powerpack on which a suitably large accumulator can be mounted. On the intelligent basic control unit with active energy-saving circuit, the required valve circuits are installed, tested and delivered on a modular basis by the Wandfluh assembly personnel in a very short time.

| Tank volume | 10.0 l |

| Motor power | 0.25 …1.5 kW |

| Pump flow rate | Up to 10.0 l/min |

| Basic control unit | Choice of Compact NG4 or Flex NG6 |

| Filtration | 6 µm |

| spin-on return filter |

BM-Reform6/F Standard powerpack

The BM-Reform6/F powerpack is used in machine tools with very demanding criteria regarding functionality and energy efficiency. In order to achieve the highest possible energy efficiency, it can be optionally equipped with a frequency converter which is mounted directly on the motor and which offers full industry 4.0 conformity. To ensure the highest oil purity for critical applications, a pressure filter can be additionally mounted. On the intelligent basic control unit with active energy-saving circuit, the required valve circuits are installed, tested and delivered on a modular basis by the Wandfluh assembly personnel in a very short time.

| Tank volume | 25.0 l |

| Motor power | 0.25 … 1.5 kW |

| Pump flow rate | Up to 19.0 l/min |

| Basic control unit | Choice of Reform NG6 or Flex NG6 |

| Filtration | 6 µm |

| spin-on return filter |

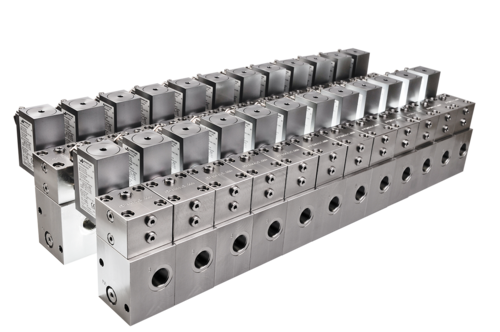

Serial powerpacks

Wandfluh specialises in highly specific powerpacks for machine tools. Special tanks are designed for installation situations with restriced space, control units and hydraulic circuits are adapted application-specifically to the machine. Apart from hydraulically controlled movements, lubrication functions are also controlled. Wandfluh powerpacks are available in a power range from 0.25 to 55 kW, with tank sizes between 3 and 1,500 litres.

Serial powerpack for grinding machines

Customer-specific serial powerpacks for grinding machines. The hydraulic powerpack has a separate lubrication circuit with a maximum pressure of 1 bar and also a high-pressure circuit for the oil supply of the hydraulic functions such as clamping, tensioning, or moving dressers.

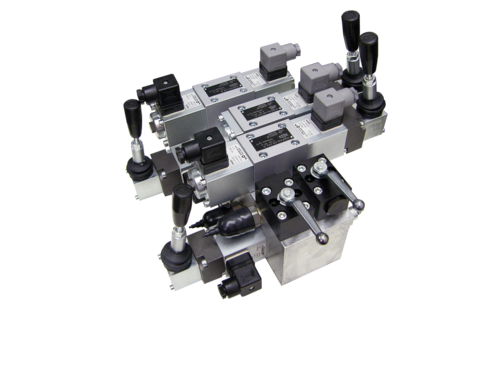

Serial powerpack for machining centres

Customer-specific serial powerpack for a compact 5-axis machining centre. The machining centre is particularly used in the watch industry. As a result, fully comprehensive extreme precision was required. The hydraulic control is designed to be decentralised. The tank with the pressure supply is located separately from the control unit.

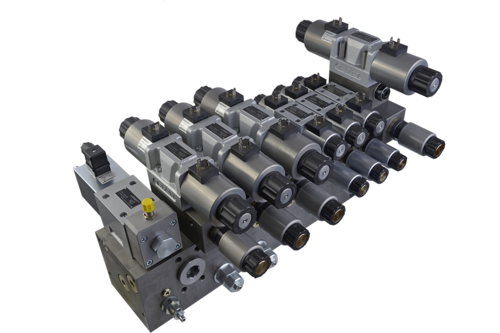

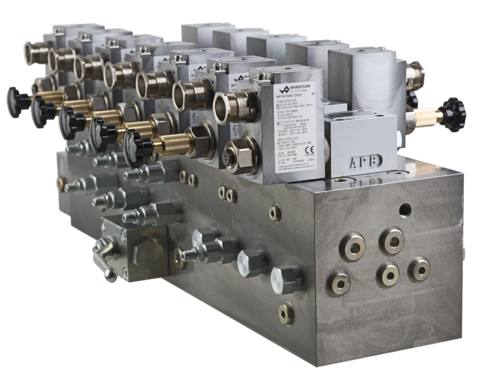

Control unit for the hydraulic start of an electrical emergency powerpack

Control units for the hydraulic start of an electrical emergency powerpack in the offshore area. Depending on the case, Wandfluh control units are developed as a modular or fully integrated construction, and manufactured at the factory in Frutigen.

Control unit for unloading systems for gas tankers

Control unit for unloading systems associated for gas tankers.Highest demands with respect to explosion protection and manual overrides for all safety relevant functions are fulfilled. Small space conditions ask for an extremely compact construction of the complex hydraulic control.

Control unit for precise docking of aircraft stairs

Control units produced in large numbers for precise docking of stairs to passenger aircrafts. These are developed with easy operation and reliability are in the foreground of this development.

Control unit for sheet metal bending machines

Control unit NG10 for fast and highly precise movements of sheet metal bending machines.