As a result of the wide diversity of hydraulic systems in lifting and lowering functions, there is a wide selection of valves available, ranging from simple throttle valves to damped flow control valves and load-compensated, seattight flow control valves. The range of variation in the specialised proportional technology can guarantee the correct choice of a proportional hydraulic valve, so that sensitive lifting and lowering is ensured in every mode of operation.

Sensitive lifting, lowering and control of heavy loads

In mobile hydraulics, lowering is usually controlled via proportional valves in the bypass. The lifting and lowering speed is generally limited by load-independent flow control valves in order not to exceed the maximum safety speed. To be able to work at higher speeds and thus more efficiently, and yet to be able to lift and lower the loads evenly and safely, a slightly more complex hydraulic circuit is required. Different hydraulic concepts can be used for this purpose.

Efficiency and Flexibility

In order to be able to use large and expensive agricultural machinery as efficiently and flexibly as possible, there is a wide range of attachments on the market that make agricultural machinery indispensable helpers for work in the field. On the one hand, these attachments can be hydraulically lifted directly on the vehicle for turning manoeuvers and crossings, and on the other hand most attachments are additionally supplied by hydraulic hoses from the agricultural machine. In addition to hydraulic motors, several cylinders are usually controlled directly in order to lift or lower heavy loads safely, similar to forklifts, lifting platforms, cranes or others.

Load-independent

For lowering the load, independence of the load is even more important than for lifting. The manufacturer of a forklift truck, for example, has to ensure, that a maximum speed is not exceeded under any circumstances - not even in case of maximum load. On the other hand, even with the fork unloaded, achieving this speed limit is desirable in order to assure a high productivity of the device. One further requirement is a good resolution in the range of lower speeds. This is necessary to lower and put down loads sensitively as well as to pick them up accurately.

Proportional flow control valves

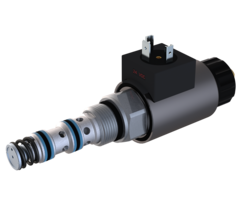

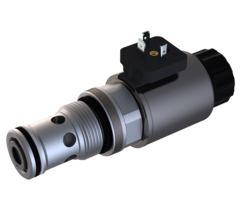

A leakage-free 2/2-way poppet valve is used for the holding function. For a controlled, sensitive and precise lowering of the load, the valve is opened and a proportionally adjustable throttle or flow control valve is actuated via a solenoid. These flow control valves differ from conventional throttle valves mainly due to the additionally integrated pressure compensator, which ensures a load-independent lowering speed. For smaller hydraulic systems, M22 valves (25 l/min) are used, for larger systems, M33 valves (up to 80 l/min). Especially in systems with multiple cylinders, the optimal coordination between volume flow and actuating accuracy is a key factor. The challenge here is to avoid the bouncing effect (swinging when lowering the load). Depending on the hydraulic version, a proportional throttle valve (DNPPM33) or a flow control valve with an internal damping system (QNPPM33) is used.

All-in-one

This solution is one of the most efficient ways to lift or lower large loads sensitively and load-compensated. It is a valve that closes in a tight fit when deenergised, thus keeping the load in a stable position. In addition, the oil quantity is controlled in a sensitive manner in proportion to the control flow and the speed is kept constant regardless of the load. QSPPU10 valves (UNF10, up to 35 l/min) are used for smaller all-in-one solutions, and M33 valves (up to 100 l/min) are used for larger hydraulic systems. Because the all-in-one solution combines multiple functions in one valve, the hydraulic diagram is considerably simplified by eliminating load holding and speed limiting valves. This results in lower costs and a compact hydraulic system in which any bouncing effect can be eliminated by default. Electric control is carried out through conventional, commercially available proportional electronics with pulse-width modulation PWM current control. In doing so, the current control ensures that the valve always works the same way, independent of the temperature.

Functioning of the all-in-one valve

This video illustrates the operation of the QSPPU10_25 seat tight 2-way proportional flow control cartridge with integrated pressure compensator. The cutaway model shows how the pressure balance spring compensates for a change in load so that the lowering speed always remains constant regardless of the load.