Page 956 - Softbound_Edition_19_en

P. 956

Proportional pressure relief valve

Proportional pressure relief valve Proportional pressure relief valve

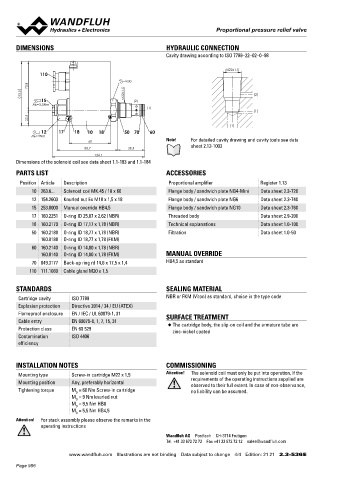

DIMENSIONS HYDRAULIC CONNECTION Proportional pressure relief cartridge with

Cavity drawing according to ISO 7789–22–02–0–98 integrated electronics M22 x 1,5

◆ pilot operated ISO 7789

M22x1.5 ◆ Q = 100 l/min

max

110 ◆ p = 400 bar

s30 ◆ p max = 350 bar

70.8 N max

93.3 M22x1.5 (2)

15 (2)

MD=5.5Nm

(1)

(1)

22.5 DESCRIPTION APPLICATION

(1) Pilot operated proportional pressure relief valve with integrated Proportional pressure relief valves with integrated electronics are

12 17 18 10 18 50 70 60 electronics as screw-in cartridge for cavity according to ISO perfectly suitable for demanding applications in which the pressure

MD=9Nm 7789. When the operating pressure adjusted by means of the pro- frequently has to be changed. They are used in applications where

60 Note! For detailed cavity drawing and cavity tools see data

sheet 2.13-1003 portional solenoid is reached, the valve opens and connects the high valve-to-valve reproducibility, easy installation, comfortable

88.7 38.5

protected line with the drain to the tank. The back pressure in T operation and high precision are very important. The integrated

134.1

Dimensions of the solenoid coil see data sheet 1.1-183 and 1.1-184 (2) affects the pressure in P (1). This proportional valve is very controller reliefs the machine control and operates the pressure

sensitively adjustable and suitable for high pressures. The Plug & control in a closed loop circuit. The applications are in the industri-

PARTS LIST ACCESSORIES Play valves are factory set and adjusted and have therefore a al as well as in the mobile hydraulics for the smooth control of

high valve-to-valve reproducibility. The control takes place via an hydraulic actuations. The screw-in cartridge is perfectly suitable

Position Article Description Proportional amplifier Register 1.13 analogue interface or a fieldbus interface (CANopen, J1939 or for installation in control blocks and is installed in sandwich-

10 263.6... Solenoid coil MK.45 / 18 x 60 Flange body / sandwich plate NG4-Mini Data sheet 2.3-720

Profibus DP). The parameterisation takes place by means of the (vertical stacked systems) and in flange plates (corresponding data

12 154.2603 Knurled nut Ex M18 x 1,5 x 18 Flange body / sandwich plate NG6 Data sheet 2.3-740 free of cost parameterisation and diagnostics software «PASO» sheets in this register). For machining the cartridge cavity in steel

15 253.8000 Manual override HB4,5 Flange body / sandwich plate NG10 Data sheet 2.3-760 or via fieldbus interface. The USB parameterisation interface is and aluminum blocks, cavity tools are available (hire or purchase).

17 160.2251 O-ring ID 25,07 x 2,62 (NBR) Threaded body Data sheet 2.9-200 accessible through a screw plug. As an option, these valves are Please refer to the data sheets in register 2.13.

18 160.2170 O-ring ID 17,17 x 1,78 (NBR) Technical explanations Data sheet 1.0-100 available with integrated controller. As feedback value genera- „PASO” is a Windows programm in the flow diagram

tors sensors with voltage or current output can be connected Note!

50 160.2188 O-ring ID 18,77 x 1,78 (NBR) Filtration Data sheet 1.0-50 directly. The available controller structures are optimised for style, which enables the intuitive adjustment and storing

160.8188 O-ring ID 18,77 x 1,78 (FKM) applications with hydraulic actuations. of all variable parameters. The data remain saved in

60 160.2140 O-ring ID 14,00 x 1,78 (NBR) case of a power failure and can also be reproduced and

transferred to other DSV.

160.8140 O-ring ID 14,00 x 1,78 (FKM) MANUAL OVERRIDE

70 049.3177 Back-up ring rd 14,6 x 17,5 x 1,4 HB4,5 as standard

110 111.1080 Cable gland M20 x 1,5

SYMBOL ACTUATION

STANDARDS SEALING MATERIAL

Cartridge cavity ISO 7789 NBR or FKM (Viton) as standard, choice in the type code (T) 2 Actuation Proportional solenoid, wet pin push

type, pressure tight

Explosion protection Directive 2014 / 34 / EU (ATEX) Connection Via device receptacle

Flameproof enclosure EN / IEC / UL 60079-1, 31

Cable entry EN 60079-0, 1, 7, 15, 31 SURFACE TREATMENT

◆ The cartridge body, the slip-on coil and the armature tube are

Protection class EN 60 529 zinc-nickel coated (P) 1

Contamination ISO 4406

efficiency

ELECTRICAL SPECIFICATIONS MANUAL OVERRIDE

INSTALLATION NOTES COMMISSIONING Protection class IP67 with suitable mating connector and HB4,5 as standard

Mounting type Screw-in cartridge M22 x 1,5 Attention! The solenoid coil must only be put into operation, if the closed housing cover

Mounting position Any, preferably horizontal requirements of the operating instructions supplied are Ramps Adjustable

observed to their full extent. In case of non-observance,

Tightening torque M = 60 Nm Screw-in cartridge no liability can be assumed. Parameterisation Via fieldbus or USB

D

M = 9 Nm knurled nut Supply voltage 12 VDC, 24 VDC

D

M = 9,5 Nm HB0 Note! Exact electrical specifications and detailed description

D

M = 5,5 Nm HB4,5

D of «DSV» electronics can be found on data sheet

Attention! For stack assembly please observe the remarks in the 1.13-76.

operating instructions

Wandfluh AG Postfach CH-3714 Frutigen

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 21 21 2.3-536 E www.wandfluh.com Illustrations are not binding Data subject to change 1/6 Edition: 20 40 2.3-537 E

Page 956