Page 944 - Softbound_Edition_19_en

P. 944

Proportional pressure relief valve

Proportional pressure relief valve Proportional pressure relief valve

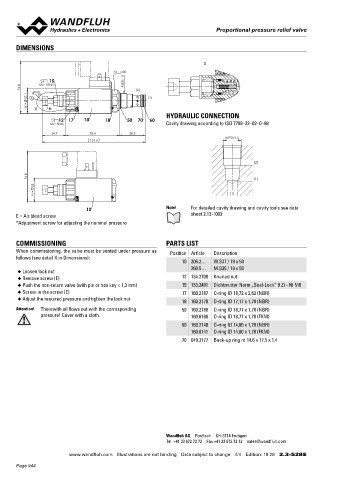

DIMENSIONS Proportional pressure relief cartridge

◆ pilot operated M22 x 1,5

X ◆ Q = 100 l/min ISO 7789

max

◆ p = 400 bar

s30 p max = 350 bar

15 M22x1.5 ◆ N max

76.8 MD=10Nm (2)

37.1 E s6 (1) DESCRIPTION APPLICATION

W = X * Pilot operated proportional pressure relief valve in screw-in The electrical remote control in conjunction with process controls

cartridge construction for cavity according to ISO 7789. High flow

allows economical solutions with repeatable processes. The

12 17 10 18 50 70 60 HYDRAULIC CONNECTION capacity, very sensitively adjustable. When the operating pressure screw-in cartridge is perfectly suitable for installation in control

MD=5Nm Cavity drawing according to ISO 7789–22–02–0–98 adjusted by means of the proportional solenoid is reached, the blocks and is installed in sandwich- (vertical stacked systems) and

34.7 78.4 38.5 valve opens and connects the protected line with the drain to the in flange plates (corresponding data sheets in this register). For

M22x1.5

151.6 tank. The back pressure in T (2) affects the pressure in P (1). For the machining the cartridge cavity in steel and aluminum blocks, cavity

control, Wandfluh proportional amplifiers are available (see tools are available (hire or purchase). Please refer to the data

register 1.13). sheets in register 2.13.

(2)

74.8 (1)

35 SYMBOL ACTUATION

M = (1) Actuation Proportional solenoid, wet pin push

(T) 2 type, pressure tight

10 Note! For detailed cavity drawing and cavity tools see data Execution W.S37 / 19 x 50 (Data sheet 1.1-173)

E = Air bleed screw sheet 2.13-1003 M.S35 / 19 x 50 (Data sheet 1.1-174)

*Adjustment screw for adjusting the nominal pressure Connection Connector socket EN 175301 – 803

(P) 1 Connector socket AMP Junior-Timer

Connector Deutsch DT04 – 2P

COMMISSIONING PARTS LIST

When commissioning, the valve must be vented under pressure as Position Article Description TYPE CODE

follows (see detail X in Dimensions): B V P PM22 - - / - #

10 206.2… W.S37 / 19 x 50 Pressure relief valve

260.5… M.S35 / 19 x 50

◆ Loosen lock nut Pilot operated

◆ Remove screw (E) 12 154.2700 Knurled nut

◆ Push the non-return valve (with pin or hex key < 1,3 mm) 15 153.2401 Dichtmutter Norm „Seal-Lock” 8 Zi - Ni M8 Proportional

◆ Screw-in the screw (E) 17 160.2187 O-ring ID 18,72 x 2,62 (NBR)

◆ Adjust the required pressure and tighten the lock nut Screw-in cartridge M22 x 1,5

18 160.2170 O-ring ID 17,17 x 1,78 (NBR)

Attention! Therewith oil flows out with the corresponding 50 160.2188 O-ring ID 18,77 x 1,78 (NBR) Nominal pressure range p 20 bar 20 200 bar 200

N

pressure! Cover with a cloth. 160.6188 O-ring ID 18,77 x 1,78 (FKM) 63 bar 63 275 bar 275

60 160.2140 O-ring ID 14,00 x 1,78 (NBR) 100 bar 100 350 bar 350

160 bar

160

160.6141 O-ring ID 14,00 x 1,78 (FKM)

70 049.3177 Back-up ring rd 14,6 x 17,5 x 1,4 Nominal voltage U 12 VDC G12

N

24 VDC G24

without coil X5

Slip-on coil Metal housing round W

Metal housing square M

Connection execution Connector socket EN 175301-803 / ISO 4400 D

Connector socket AMP Junior - Timer J

Connector Deutsch DT04 - 2P G

Sealing material NBR

FKM (Viton) D1

Manual override Manual override HB4,5

Screw plug HB0

Wandfluh AG Postfach CH-3714 Frutigen Design index (subject to change)

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com 2.3-529

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 19 28 2.3-528 E www.wandfluh.com Illustrations are not binding Data subject to change 1/3 Edition: 17 41 2.3-529 E

Page 944