Page 916 - Softbound_Edition_19_en

P. 916

10

15

P 20 10 20

7,5 4,2 ∗ A B G1/8"

Ø Ø 21 11 30

T To

5,5 24,5 53 19

Pressure reducing valve

30 72 Pressure reducing valves Pressure reducing valves

16

2

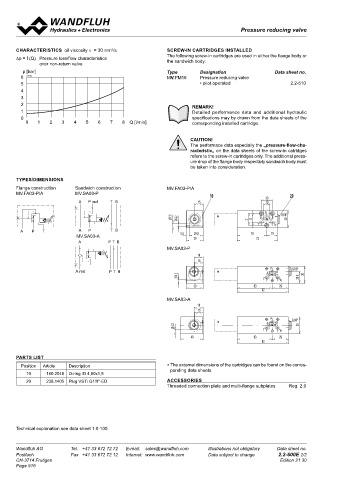

CHARACTERISTICS oil viscosity υ = 30 mm /s SCREW-IN CARTRIDGES INSTALLED Pressure reducing valve

15 The following screw-in cartridges are used in either the flange body or

∆p = f (Q) Pressure loss/flow characteristics Flange- and sandwich construction

over non-return valve A P B G1/8" the sandwich body: • Q = 8 l/min ®

∗

4,2 30 max NG3-Mini

p [bar] T To 20,5 Type Designation Data sheet no. • p = 315 bar

Ø

6 K0130 30 63 29 MV.PM18 Pressure reducing valve • p max = 200 bar

5 92 • pilot operated 2.2-510 N red max

4

3 16 DESCRIPTION FUNCTION APPLICATION

2 15 REMARK! Flange or sandwich type directly operated The spool is held in the home position by the Pressure reducing valves are used for keeping

1 ∗ P G1/8" Detailed performance data and additional hydraulic 3-way pressure reducing valve NG3-Mini in spring. The connection to the consumer is fully the pressure constant in a consumer, irrespec-

open. The reduced pressure can be adjusted at

accordance with Wandfluh standard. The

tive of pressure fluctuations on the supply side.

0 4,2 A B 30 specifications may by drawn from the data sheets of the

Ø 0 1 2 3 4 5 6 7 T 8 To Q [l/min] corresponding installed cartridge. valve reduces the inlet pressure to a preset the adjustment spindle, irrespective of the inlet If several consumers are used, the reduced

output pressure. The integrated pressure relief

pressure can be set individually with the aid if

pressure. If the reduced pressure increases,

40 63 29 function prevents the reduced pressure from it displaces the valve towards the spring. The one pressure control valve for each consumer.

92 being exceeded as a result of external forces. volume flow at the valve inlet is then throttled, Generally speaking, pressure control valves

CAUTION! Two types of setting and four pressure stages controlling the reduced pressure. If forces are used for reducing a hydraulic pressure to

The performace data especially the „pressure-flow-cha- are available. A pressure gauge connection acting on the consumer allow the reduced a lower level. The integrated pressure relief

racteristic„ on the data sheets of the screw-in catridges

refere to the screw-in cartridges only. The additional press- is provided in the reduced connection. The pressure to be increased above the set value, function obviates the need for any additional

pressure relief valve in the reduced pipe. Di-

the spool is displaced until the valve inlet closes

flange valve body is painted, the other parts

ure drop of the flange body respectivly sandwich body must

be taken into consideration. are zinc-nickel coated. and the tank port opens. The pressure increase rectly operated pressure reducing valves also

is then limited to a low value, controlled by keep the reduced pressure stable, even under

the spring. very difficult operating conditions. Mini-3 valves

TYPES/DIMENSIONS are used where both, reduced dimensions and

Flange construction Sandwich construction MV.FA03-P/A weight are important.

MV.FA03-P/A MV.SA03-P

10 20 20

A P red T B 15 10

P TYPE CODE

7,5 4,2 ∗ A B G1/8"

Ø Ø 21 11 30 M D A03 - - #

T To

A P T A P T B 5,5 24,5 53 19 Pressure reducing valve

MV.SA03-A 30 72 Direct operated

A P T B

MV.SA03-P Type of adjustment Key S

Control knob

D

16 Flange construction F

15 Sandwich construction S

P G1/8" Mounting interface acc. to Wandfluh standard, NG3-Mini

A red P T B ∗ A B

4,2 30 Type list / function Flange design Sandwich design

Ø 20,5

T To P → A P/A in P P

A P T B 30 63 29

92

Pressure range p N red 32 bar 32

MV.SA03-A 80 bar 80

16 200 bar 200

15

A P T B red P Design-Index (Subject to change)

∗ A B G1/8"

4,2 30

Ø

T To

40 63 29

92

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

PARTS LIST Description Direct operated pressure reducing valve Fluid Mineral oil, other fluid on request

ISO 4406:1999, class 1816/13

Contamination efficiency

NG3-Mini according to Wandfluh standard

Nominal size

Position Article Description ∗ The external dimensions of the cartridges can be found on the corres- Constructions Flange- or sandwich (Required filtration grade ß 6…10≥75)

ponding data sheets. Mounting 3 mounting holes for zyl. screws M4 or refer to data sheet 1.0-50/2

10 160.2045 O-ring ID 4,50x1,5 double ended screws M4 Viscosity range 12 mm /s…320 mm /s

2

2

20 238.1405 Plug VSTI G1/8"-ED ACCESSORIES Connections Threaded connection plates Fluid temperature -20…+70 °C

Threaded connection plate and multi-flange subplates Reg. 2.9 Multi-flange plates Peak pressure p = 315 bar

Longidutinal stacking system Tank load in connection T p max = 50 bar

T max

Ambient temperature -20…+50 °C Nominal pressure p N red = 32 bar, 80 bar and 200 bar

Mounting position any Volume flow Q = 0…8 l/min

A P red T B Fastening torque M = 2,8 Nm (quality 8.8)

D

Weight m = 0,54 kg (Flange, Sandwich P)

Technical explanation see data sheet 1.0-100

A P T A P T B

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory P T B Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

A

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.2-600E 2/2 Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.2-605E 1/2

CH-3714 Frutigen Edition 21 30 CH-3714 Frutigen Edition 21 30

Page 916

A red P T B

A P T B

A P T B red