Page 888 - Softbound_Edition_19_en

P. 888

Accumulator unloading valve Accumulator unloading valves

Accumulator loading valves

2

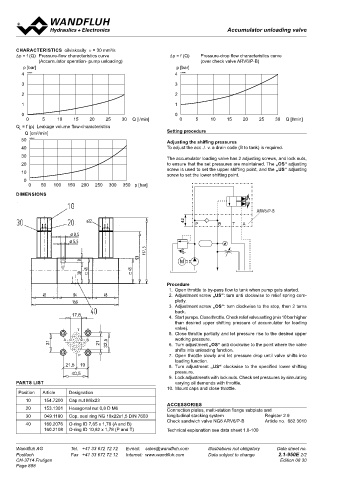

CHARACTERISTICS oilviskosity υ = 30 mm /s Accumulator unloading valve

∆p = f (Q) Pressure-flow characteristics curve ∆p = f (Q) Pressure-drop flow characteristics curve Sandwich construction

(Accumulator operation- pump unloading) (over check valve ARV6/P-B) • 1-point adjustment NG10

p [bar] p [bar]

4 K0597 4 K0598 • Pilot operated ISO 4401-05

• Q = 30 l/min

3 3 • p max = 400 bar

• p max = 350 bar

2 2 N max

1 1 DESCRIPTION FUNCTION APPLICATION

Sandwich type pilot operated accumulator un- If the P pressure exceeds the adjustable un- Accumulator loading valves are used in hydrau-

0 0 loading valve. Mounting interface acc. to ISO loading point, the pilot spool is opening the lic systems with accumulators. They allow a low

0 5 10 15 20 25 30 Q [l/min] 0 5 10 15 20 25 30 Q [l/min] 4401-05. The valve is available with two types pilot valve. A control flow starts to flow and the cost, energy saving system design in cases

Q = f (p) Leakage volume flow-characteristics of setting, both interlockable. There are three back end of the main spool is depressurised. where the cylinder flow demand varies consi-

L

3

Q [cm /min] B Setting procedure pressure stages to choose from. The valve has The resultant pressure difference displaces the derably or for retaining pressures over a period

main spool towards the spring and the valve

an adjustable unloading point and a defined

of time, e.g. for clamping processes. Note: An

B 50 K0587 Adjusting the shiffing pressures re-switching difference. The steel bodies of switches to unloading circulation. Because of additional relief valve for system protection

40 P T To adjust the acc ./. v. a drain code (B to tank) is required. the sandwich valve are phosphate coated. the difference in section in the pilot aerea, the must be installed. Please refere to the set-up

P 30 T The accumulator loading valve has 2 adjusting screws, and lock nuts, Steel cartridge body and adjustment spindle pilot flow is interrupted as soon as the pressure and connection exemple on page 2.

galvanised to protect them against corrosion.

in the accumulator drops by 15 % or 25 % of

20 A to ensure that the set pressures are maintained. The „OS“ adjusting The aluminium knob has a natural anodised the upper switching point. The pressures at

A screw is used to set the upper shifting point, and the „US“ adjusting finish. The quality of this product is reflected in the main spool are equilibrated and the spring

10 screw to set the lower shifting point. the good performance data and design. displaces the main spool to the closed position.

0 The pump can now build up the system pres-

0 50 100 150 200 250 300 350 p [bar] sure again as far as the unloading point and

the cycle starts again.

DIMENSIONS

ARV6/P-B

ARV6/P-B TYPE CODE

42

42 P B T A US S A10 - P #

P B T A

Accumulator unloading valve pilot operated

∗ ∗ Type of adjustment screw S

knob D

M

M Sandwich construction

International standard interface ISO, NG10

Type list / function in P

Procedure

1. Open throttle to by-pass flow to tank when pump gets started. Pressure range p 100 bar 100

2. Adjustment screw „US“: turn anti clockwise to relief spring com- N 160 bar 160

pletly. 350 bar 350

3. Adjustment screw „OS“: turn clockwise to the stop, then 2 turns

back. Design-Index (Subject to change)

4. Start pumpe. Close throttle. Check relief valve setting (min 10 bar higher

than desired upper shifting pressure of accumulator for loading

valve).

5. Close throttle partially and let pressure rise to the desired upper GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

working pressure. Description Pilot operated accumulator unloading valve Fluid Mineral oil, other fluid on request

6. Turn adjustment „OS“ anti clockwise to the point where the valve Norminal size NG10 according to ISO 4401-05 Contamination efficiency ISO 4406:1999, class 18/16/13

shifts into unloading function. Construction Sandwich construction (Required filtration grade ß6…10≥75)

7. Open throttle slowly and let pressure drop until valve shifts into Mounting 4 holes for socket cap screw M6 refer to data sheet 1.0-50/2

loading function. or studs M6 Viskosity range 12 mm /s…320 mm /s

2

2

8. Turn adjustment „US“ clockwise to the specified lower shifting Connections Connection plates Fluid temperature -20…+70 °C

pressure. Multi-station flange subplate Peak pressure p max = 400 bar

9. Lock adjustments with lock nuts. Check set pressures by simulating Longitudinal stacking system Norminal pressure p = 100 bar, p = 160 bar, p = 350 bar

N

N

N

PARTS LIST varying oil demands with throttle. Mounting position any Minimum pressure p = 50 bar for p 160 / 350 bar

N

min

10. Mount caps and close throttle. Ambient temperature -20...+50 °C p = 25 bar for p 100 bar

min

N

Position Article Designation Fastening torque M = 9,5 Nm (Qual 8.8) for fixing screw Diff. unloading/loading 15 ± 3 % for p = 160 / 350 bar

D

N

10 154.7200 Cap nut M6x23 M = 50 Nm for screw cartridge 25 ± 3 % for p = 100 bar

N

D

ACCESSORIES

min

20 153.1301 Hexagonal nut 0,8 D M6 Connection plates, multi-station flange subplate and Weight m = 2,7 kg Volume flow Q = 1…30 l/min

(over 30 l/min on request)

30 049.1180 Cop. seal ring NG 18x22x1,5 DIN 7603 longitudinal stacking system Register 2.9 Leakage volume flow Maximum 4 drops/min

Check sandwich valve NG6 ARV6/P-B Article no. 662.3010 in accumulator operation P - T

40 160.2076 O-ring ID 7,65 x 1,78 (A and B)

160.2108 O-ring ID 10,82 x 1,78 (P and T) Technical explanation see data sheet 1.0-100 For further hydraulic characteristics refer to data sheet: 2.1-548

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.1-950E 2/2 Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.1-960E 1/2

CH-3714 Frutigen Edition 08 30 CH-3714 Frutigen Edition 03 35

Page 888