Page 290 - Softbound_Edition_19_en

P. 290

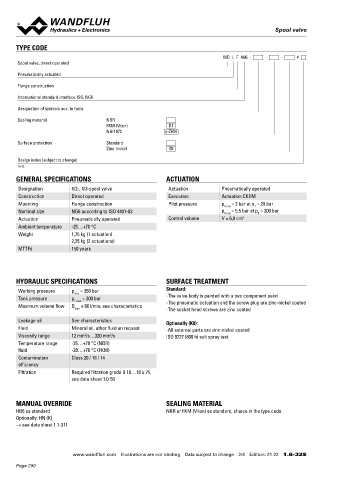

Spool valve

Spool valve Spool valve

TYPE CODE PERFORMANCE SPECIFICATIONS

2

WD L F A06 - - - # Oil viscosity u = 30 mm /s

Spool valve, direct operated p = f (Q) Performance limits Q = f (Q) Leakage volume flow characteristics

L

Pneumatically actuated per control edge

3

p [bar] Q [cm /min]

Flange construction K4259 150 K0232_3

350

300 120

International standard interface ISO, NG6

250 90

200

Designation of symbols acc. to table

150 60

100

Sealing material NBR 50 30

FKM (Viton) D1 0 0

NBR 872 y-Z604 0 10 20 30 40 50 60 70 80 Q [l/min] 0 50 100 150 200 250 300 350 p [bar]

AB3/AB1/ACB/ADB/AFB/AGB

Surface protection Standard BEA

Zinc-nickel K8

Δp = f (Q) Pressure drop-volume flow characteristics Volume flow direction

Design index (subject to change)

1.6-32 ∆p [bar] Symbol P - A P - B P - T A - T B - T

30 K0171 5 AB1 / AB2 / AB3 2 2 - 1 1

GENERAL SPECIFICATIONS ACTUATION 25 1 ACB / AC1 / CB2 2 2 - 1 1

Designation 4/2-, 4/3-spool valve Actuation Pneumatically operated 20 2 ADB / AD1 / DB2 2 2 - 3 3

Construction Direct operated Execution Actuation CKIIM 15 3 4 BEA / BE1 / EA2 2 2 5 2 2

10

Mounting Flange construction Pilot pressure p V min = 2 bar at p = 20 bar 5 AFB / AF1 / FB2 4 4 - 3 3

T

Nominal size NG6 according to ISO 4401-03 p V min = 5,5 bar at p = 200 bar 0

T

Actuation Pneumatically operated Control volume V = 6,9 cm 3 0 10 20 30 40 50 60 70 80 Q [l/min] AGB / AG1 / GB2 4 4 - 1 1

Ambient temperature -25…+70 °C

Weight 1,75 kg (1 actuation)

2,25 kg (2 actuations) DIMENSIONS

MTTFd 150 years 4/3-way valve (spring centred) 4/2-way valve (spring reset)

4/2-way valve (impulse)

9.5

5.2 MD=5.2Nm

G1/8"

8

HYDRAULIC SPECIFICATIONS SURFACE TREATMENT

Working pressure p = 350 bar Standard:

max -The valve body is painted with a two component paint 45 49

Tank pressure p = 200 bar 41

T max -The pneumatic actuation and the screw plug are zinc-nickel coated

Maximum volume flow Q = 80 l/min, see characteristics

max -The socket head screws are zinc coated

10 20 10 50 30

Leakage oil See characteristics Optionally (K8): 186 MD=5.2Nm 54 68 12.6 MD=60Nm

Fluid Mineral oil, other fluid on request -All external parts are zinc-nickel coated 139.6

Viscosity range 12 mm /s…320 mm /s ISO 9227 (800 h) salt spray test

2

2

Temperature range -25…+70 °C (NBR)

fluid -20…+70 °C (FKM) HYDRAULIC CONNECTION PARTS LIST

Contamination Class 20 / 18 / 14 Position Article Description

efficiency 17.8 10 254.4059 Pneumatic actuation CKIIM

Filtration Required filtration grade ß 10…16 ≥ 75, T 20 246.2160 Socket head screw M5 x 60 DIN 912

see data sheet 1.0-50 A B

31 21 32.5 30 239.2210 Socket head screw M20 x 1

50 160.2093 O-ring ID 9,25 x 1,78 (NBR)

P 160.6092 O-ring ID 9,25 x 1,78 (FKM)

MANUAL OVERRIDE SEALING MATERIAL 21.5

HB6 as standard NBR or FKM (Viton) as standard, choice in the type code 40.5

Optionally: HN (K)

→ see data sheet 1.1-311

www.wandfluh.com Illustrations are not binding Data subject to change 2/4 Edition: 21 22 1.6-32 E www.wandfluh.com Illustrations are not binding Data subject to change 3/4 Edition: 21 22 1.6-32 E

Page 290