Page 248 - Softbound_Edition_19_en

P. 248

Spool valve

Spool valve Spool valve

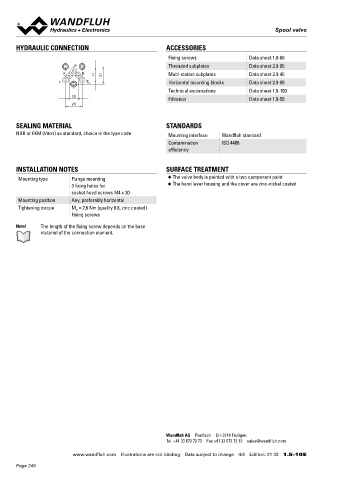

HYDRAULIC CONNECTION ACCESSORIES Spool valve

NG3-Mini

Fixing screws Data sheet 1.0-60 Flange construction

P Threaded subplates Data sheet 2.9-05 ◆ roller operated

A B 11 21 Multi-station subplates Data sheet 2.9-45 ◆ 4/2-way with spring reset

◆ Q = 8 l/min

T T 0 Horizontal mounting blocks Data sheet 2.9-85 max

◆ p = 350 bar

Technical explanations Data sheet 1.0-100 max

10

Filtration Data sheet 1.0-50

20

DESCRIPTION APPLICATION

Direct operated valve, roller operated with 4 connections in 5 Spool valves are mainly used for controlling direction of movement

SEALING MATERIAL STANDARDS chamber design. Without actuation, the spool is switched back to and stopping of hydraulic cylinders and motors. The direction of

NBR or FKM (Viton) as standard, choice in the type code Mounting interface Wandfluh standard the offset position. Precise spool fit, low leakage, long service life movement is determined by the position of the spool and its symbol.

Manually or mechanically operated valves are particularly suitable

time. Spool made from hardened steel, body from high quality

Contamination ISO 4406 hydraulic cast steel. for use in installations where no electric current is available or for

efficiency applications in explosion hazard areas. Miniature values are used

where both, reduced dimensions and weight are important.

INSTALLATION NOTES SURFACE TREATMENT

Mounting type Flange mounting ◆ The valve body is painted with a two component paint

3 fixing holes for ◆ The hand lever housing and the cover are zinc-nickel coated TYPE CODE

socket head screws M4 x 30 WD T F A03 - - #

Mounting position Any, preferably horizontal Spool valve, direct operated

Tightening torque M = 2,6 Nm (quality 8.8, zinc coated) Roller with spring reset

D

Fixing screws

Flange construction

Note! The length of the fixing screw depends on the base

material of the connection element. Mounting interface acc. to Wandfluh standard, NG3-Mini

Designation of symbols acc. to table Operation a-side …1

Operation b-side …2

Sealing material NBR

FKM (Viton) D1

Design index (subject to change)

1.5-15

GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

Designation 4/2-spool valve Working pressure p = 350 bar (p < 20 bar)

T

max

Construction Direct operated p = 315 bar (p > 20 bar)

max

T

Mounting Flange construction Tank pressure p T max = 100 bar

Nominal size NG3-Mini according to Wandfluh Maximum volume flow Q = 8 l/min, see characteristics

max

standard Leakage oil See characteristics

Actuation Roller actuated Fluid Mineral oil, other fluid on request

2

2

Ambient temperature -25…+70 °C Viscosity range 12 mm /s…320 mm /s

Weight 0,62 kg Temperature range -25…+70 °C (NBR)

MTTFd 150 years fluid -20…+70 °C (FKM)

Contamination Class 20 / 18 / 14

efficiency

Filtration Required filtration grade ß 10…16 ≥ 75,

see data sheet 1.0-50

ACTUATION

Actuation Roller

Actuation stroke s = 1,7 mm

Actuation force F = 90 - 120 N

Wandfluh AG Postfach CH-3714 Frutigen b

Tel. +41 33 672 72 72 Fax +41 33 672 72 12 sales@wandfluh.com

www.wandfluh.com Illustrations are not binding Data subject to change 4/4 Edition: 21 33 1.5-10 E www.wandfluh.com Illustrations are not binding Data subject to change 1/3 Edition: 21 33 1.5-15 E

Page 248