Page 19 - Softbound_Edition_19_en

P. 19

Filtering

Filtering

CONTAMINATION IN HYDRAULIC UNITS

One differentiates between the following kinds of contamination:

Initial contamination:

This contamination takes place during the erection and commissioning of the hydraulic units.

(Dust, swarf, rust, hammer scale, packaging residues, etc.)

Contamination by new oil:

The oil supplied by the oil supplier is often contaminated, therefore the oil definitely must be filtered before filling it into the unit.

Contamination during operation:

Entry of dirt into the hydraulic tank due to insufficient ventilation, piston rod seals, etc.

FILTER / DEGREE OF CONTAMINATION

In the Wandfluh product documentation, degrees of contamination and recommended filters are indicated as follows:

Example:

Maximum admissible degree of contamination ISO 4406:1999, class 18/16/13

Recommended filter with retention rate ß 6…10 ≥ 75

CONTAMINATION CLASSES

The contaminations classes indicate how many particles of a certain size are contained in 100 ml of hydraulc fluid. Usually control- and proportional

valves are the components most sensitive to contamination in the hydraulic unit. Therefore they determine the overall degree of contamination of

the hydraulic oil. At the moment, 5 classification systems are available (ISO 4406:1999, resp. NAS 1638 , SAE, Mil. std. 1246A). In the Wandfluh

product documentation the maximum admissible degrees of contamination are indicated in classes in accordance with ISO 4406:1999.

RETENTION RATE / BETA - VALUE

The retention rate of a filter element is the measure for the separation capacity of the filter for defined particle sizes. It is defined by the beta-value

(ß x) The ß x value is the ratio of all particles > x µm before the filter, to the particles > x µm after the filter.

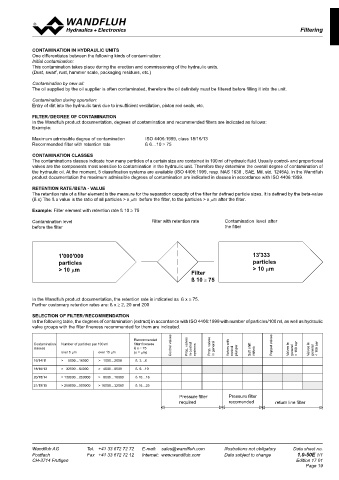

Example: Filter element with retention rate ß 10 ≥ 75

Contamination level Filter with retention rate Contamination level after

before the filter the filter

1'000'000 13'333

particles particles

> 10 µm > 10 µm

Filter

ß 10 ≥ 75

In the Wandfluh product documentation, the retention rate is indicated as ß x ≥ 75.

Further customary retention rates are: ß x ≥ 2, 20 und 200

SELECTION OF FILTER / RECOMMENDATION

In the following table, the degrees of contamination (extract) in accordance with ISO 4406:1999 with number of particles/100 ml, as well as hydraulic

valve groups with the filter fineness recommended for them are indicated.

Recommended

Contamination Number of particles per 100 ml filter fineness Control valves Poppet valves

classes ß x ≥ 75 Prop. valves in control systems Prop. valves in general Valves with Soft shift Valves in > 160 bar Valves in < 160 bar

over 5 µm over 15 µm (x = µm) control plunger valves general general

16/14/11 > 8000…16000 > 1000…2000 ß 3…6

18/16/13 > 32000…64000 > 4000…8000 ß 6…10

20/18/14 > 130000…250000 > 8000…16000 ß 10…16

21/19/15 > 250000…500000 > 16000…32000 ß 16…25

Pressure filter Pressure filter

required recomended return line filter

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 1.0-50E 1/1

CH-3714 Frutigen Edition 17 01

Page 19