Page 1145 - Softbound_Edition_19_en

P. 1145

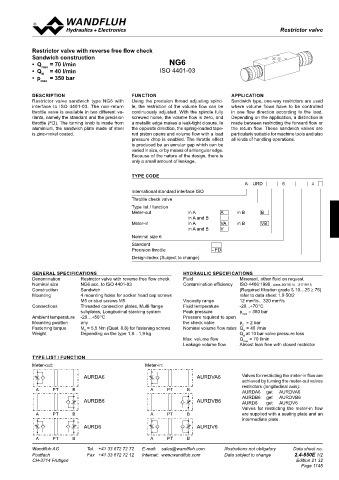

Restrictor valve

Restrictor valves Restrictor valves

CHARACTERISTICS Oil viscosity υ = 30 mm /s Restrictor valve with reverse free flow check

2

∆p = f (Q) Pressure loss/flow characteristics Q = f (n) Volume flow adjustment characteristics Sandwich construction

(Standard) • Q = 70 l/min NG6

max

p [bar] Q [l/min] • Q = 40 l/min ISO 4401-03

25 K0150 20 K0147 ∆ p = 20 bar • p N = 350 bar

20 15 max

15 ∆ p = 10 bar

10 ∆ p = 5 bar DESCRIPTION FUNCTION APPLICATION

10 Restrictor valve sandwich type NG6 with Using the precision thread adjusting spind- Sandwich type, one-way restrictors are used

5

5 interface to ISO 4401-03. The non-return le, the restriction of the volume flow can be where volume flows have to be controlled

0 0 throttle valve is available in two different va- continuously adjusted. With the spindle fully in one flow direction according to the load.

riants, namely the standard and the precision

Depending on the application, a distinction is

screwed home, the volume flow is zero, and

0 5 10 15 20 Q [l/min] 0 0.5 1 1.5 2 2.5 3 3.5 n [-]

∆p = f (Q) Pressure loss/flow characteristics Q = f (n) Volume flow adjustment characteristics throttle (FD). The turning knob is made from a metallic edge makes a leak-tight closure. In made between restricting the forward flow or

the opposite direction, the spring-loaded tape-

aluminium, the sandwich plate made of steel

the return flow. These sandwich valves are

over non-return valve (Precision throttle) is zinc-nickel coated. red piston opens and volume flow with a load particularly suitable for machine tools and also

p [bar] Q [l/min] pressure drop is enabled. The throttle effect all kinds of handling operations.

25 K0151 25 K0148 is produced ba an annular gap which can be

∆ p = 20 bar

20 20 varied in size, or by means of a triangular edge.

Because of the nature of the design, there is

15 15 ∆ p = 10 bar only a small amount of leakage.

10 10 ∆ p = 5 bar

5 5 TYPE CODE

0 0 A URD 6 #

0 5 10 15 20 Q [l/min] 0 1 2 3 4 5 n [-] International standard interface ISO

Q = f (n) Volume flow adjustment characteristics

(Precision throttle) Throttle check valve

Q [l/min] Type list / function

A PT B A PT B ∆ p = 20 bar

0.4 K0149 Meter-out in A A in B B

in A and B

0.3 ∆ p = 10 bar Meter-in in A VA in B VB

PARTS LISTS ∆ p = 5 bar in A and B V

A PT B 0.2 A PT B

Position Article Description Nominal size 6

0.1 Standard

10 160.2052 O-ring ID 5,28x1,78 Precision throttle - FD

15 160.2067 O-ring ID 6,75x1,78 0

A

in line with check valve PT B 0 0.5 A 1 PT 1.5 B 2 2.5 n [-] Design-Index (Subject to change)

20 114.1204 Turning knob

30 173.1650 Sealing plate BDB4 GENERAL SPECIFICATIONS HYDRAULIC SPECIFICATIONS

40 173.1700 Intermediate plate BZB4 Technical explanation see data sheet 1.0-100 Denomination Restrictor valve with reverse free flow check Fluid Mineraoil, other fluid on request

Nominal size NG6 acc. to ISO 4401-03 Contamination efficiency ISO 4406:1999, class 20/18/14…21/19/15

DIMENSIONS Construction Sandwich (Required filtration grade ß 10…25 ≥ 75)

Mounting 4 mounting holes for socket head cap screws refer to data sheet 1.0-50/2

20 28 M5 or stud screws M5 Viscosity range 12 mm /s…320 mm /s

2

2

14 Connections Threaded connection plates, Multi-flange Fluid temperature -20...+70 °C

subplates, Longitudinal stacking system Peak pressure p max = 350 bar

Ambient temperature -20…+50 °C Pressure required to open

P Mounting position any the check valve p = 2 bar

ö

Meter-out: ∅ 5,5 A B Fastening torque M = 5,5 Nm (Qual. 8.8) for fastening screws Nominal volume flow rates Q = 40 l/min

40 28,5 27 T To 14 Weight Depending on the type 1,8…1,9 kg Q at 10 bar valve pressure loss

N

D

Max. volume flow Q N = 70 l/min

max

Leakage volume flow Almost leak free with closed restrictor

44 27

30

A=71 TYPE LIST / FUNCTION

B=71

40 30 37 88 37 Meter-out: Meter-in:

15 AURDA6 AURDVA6 Valves for restricting the meter-in flow are

achieved by turning the meter-out valves

P A PT B A PT B restrictors (longitudinal axis):

A B AURDA6 get AURDVA6

T To AURDB6 AURDVB6 AURDB6 get AURDVB6

Meter-in: AURD6 get AURDV6

Valves for restricting the meter-in flow

A PT B A PT B are supplied with a sealing plate and an

1,5 30 1,5 10 VA=71 intermediate plate.

VB=71 AURD6 AURDV6

V=88

A PT B A PT B

Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no. Wandfluh AG Tel. +41 33 672 72 72 E-mail: sales@wandfluh.com Illustrations not obligatory Data sheet no.

Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.4-835E 2/2 Postfach Fax +41 33 672 72 12 Internet: www.wandfluh.com Data subject to change 2.4-850E 1/2

CH-3714 Frutigen Edition 03 40 CH-3714 Frutigen 20 21,5 19 Edition 21 32

17,8 Page 1145

T

∅ 5,5 45 ∅ 35 31 A B 21 32,5

P

60 32

42 A=92

B=92

49 120 49

40 30 10 15

T

A B

P

VA=92

1,5 42 1,5 VB=92

V=120