Page 1017 - Softbound_Edition_19_en

P. 1017

Proportional pressure reducing valve

Proportional pressure reducing valve

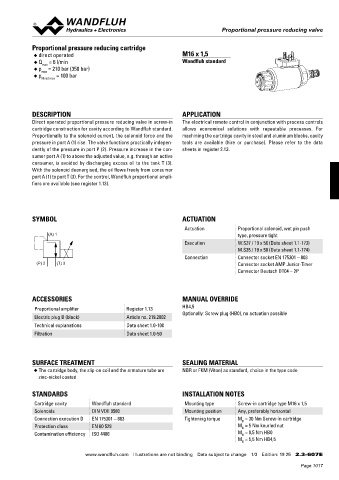

Proportional pressure reducing cartridge

◆ direct operated M16 x 1,5

◆ Q = 6 l/min Wandfluh standard

max

◆ p = 210 bar (350 bar)

max

◆ p = 100 bar

N red max

DESCRIPTION APPLICATION

Direct operated proportional pressure reducing valve in screw-in The electrical remote control in conjunction with process controls

cartridge construction for cavity according to Wandfluh standard. allows economical solutions with repeatable processes. For

Proportionally to the solenoid current, the solenoid force and the machining the cartridge cavity in steel and aluminum blocks, cavity

pressure in port A (1) rise. The valve functions practically indepen- tools are available (hire or purchase). Please refer to the data

dently of the pressure in port P (2). Pressure increase in the con- sheets in register 2.13.

sumer port A (1) to above the adjusted value, e.g. through an active

consumer, is avoided by discharging excess oil to the tank T (3).

With the solenoid deenergised, the oil flows freely from consumer

port A (1) to port T (3). For the control, Wandfluh proportional ampli-

fiers are available (see register 1.13).

SYMBOL ACTUATION

Actuation Proportional solenoid, wet pin push

(A) 1 type, pressure tight

Execution W.S37 / 19 x 50 (Data sheet 1.1-173)

M.S35 / 19 x 50 (Data sheet 1.1-174)

Connection Connector socket EN 175301 – 803

(P) 2 (T) 3 Connector socket AMP Junior-Timer

Connector Deutsch DT04 – 2P

ACCESSORIES MANUAL OVERRIDE

Proportional amplifier Register 1.13 HB4,5

Electric plug B (black) Article no. 219.2002 Optionally: Screw plug (HB0), no actuation possible

Technical explanations Data sheet 1.0-100

Filtration Data sheet 1.0-50

SURFACE TREATMENT SEALING MATERIAL

◆ The cartridge body, the slip-on coil and the armature tube are NBR or FKM (Viton) as standard, choice in the type code

zinc-nickel coated

STANDARDS INSTALLATION NOTES

Cartridge cavity Wandfluh standard Mounting type Screw-in cartridge type M16 x 1,5

Solenoids DIN VDE 0580 Mounting position Any, preferably horizontal

Connection execution D EN 175301 – 803 Tightening torque M = 30 Nm Screw-in cartridge

D

Protection class EN 60 529 M = 5 Nm knurled nut

D

Contamination efficiency ISO 4406 M = 9,5 Nm HB0

D

M = 5,5 Nm HB4,5

D

www.wandfluh.com Illustrations are not binding Data subject to change 1/3 Edition: 19 25 2.3-607 E

Page 1017