The inductive switching technology

As a result of the modular structure of the WANDFLUH product range, the spool and poppet valves with the nominal sizes NG4, NG6 and NG10 can be supplemented by simple or redundant switching position monitoring. The inductive switching technology used offers a lot of security as a result of its contact-free and therefore wear-free switching properties.

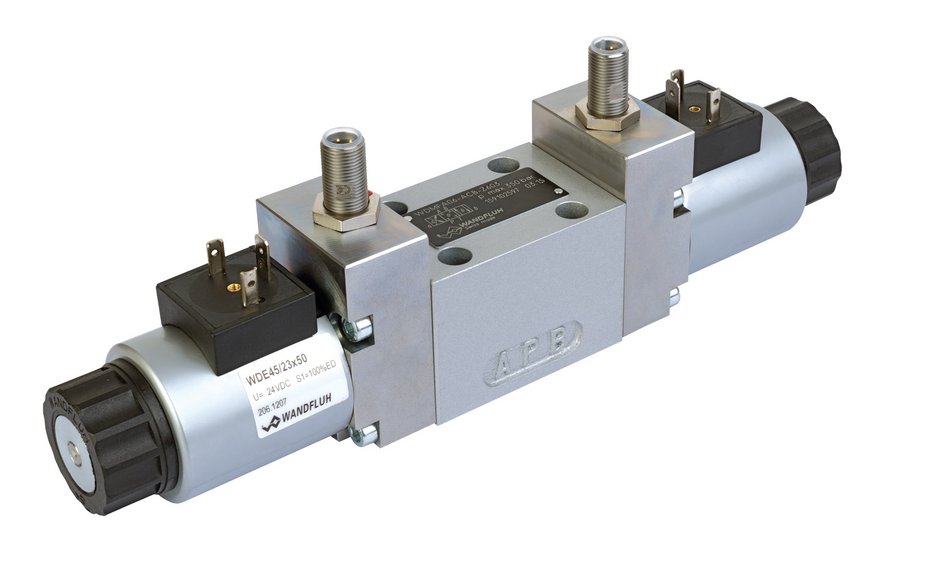

- Redundant switching position monitoring integrated in a Wandfluh spool valve.

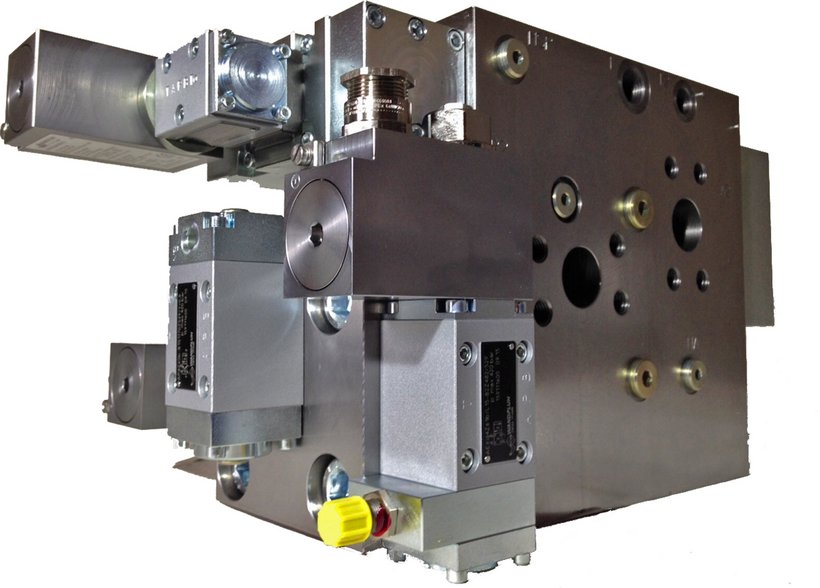

- Switching position monitoring integrated in a safety relevant hydraulic application.

Product description

Inductive switching technology is a very long lasting and secure method for monitoring the switching positions of a valve. By applying an electrical voltage, a magnetic field is generated at the tip of the switch. In the case of approaching magnetisable material, e.g. a valve spool, this magnetic field changes and this is something which results in an activation of the switch. The advantages over a mechanical switch are not just in terms of wear and tear, but in particular, they also lie in the early detection of a cable break or defective switch.

Characteristics

- Very secure switching characteristics as a result of inductive switching technology

- Wear free operation of the inductive switches

- Simple or redundant execution is possible

- Very long service life

Applications

- Installation in safety valves in the case of monitored systems

- In the case of pre-defined movement sequences with a risk of injury or accident in the case of system failure

- For controlling large forces as a switching point sensor (hydroelectric power station)

- For releasing successive valves in a complex hydraulic system

Further information

Further information can be found on www.wandfluh.comOr we will be happy to advise you in the selection of the suitable components or in the layout of your application.